The intricacies of 4Wrd Rexroth systems are vital in the advancement of industrial automation and robotics. As a leading technology in motion control solutions, 4Wrd Rexroth combines precision with flexibility, contributing to more efficient and reliable manufacturing processes. Delve into its applications, benefits, and industry impact through an expert analysis that clarifies its strategic role in modern industry settings.

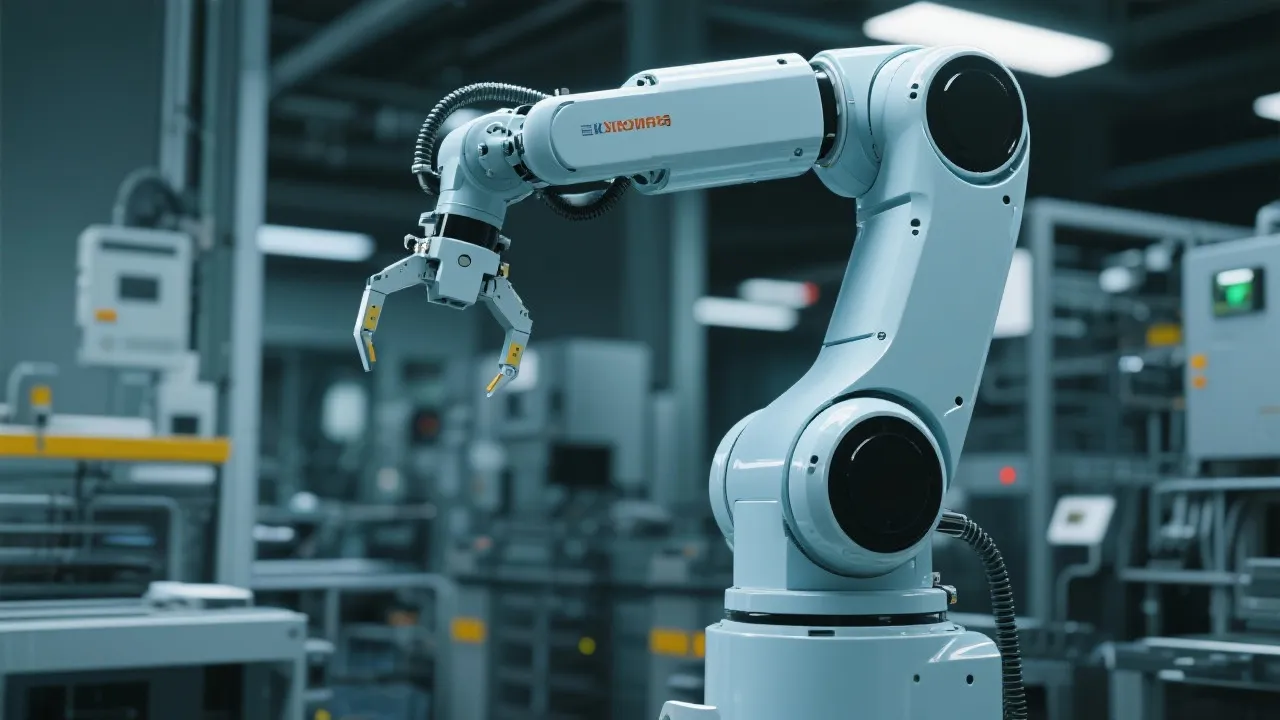

The 4Wrd Rexroth system stands at the forefront of industrial automation, influencing the dynamics of manufacturing and robotic operations. Known for its precision and adaptability, Rexroth products integrate seamlessly into a variety of applications, ensuring reliable and efficient performance across different sectors. The system's motion control capabilities are particularly valued for their contribution to enhanced productivity and operational flexibility. The advanced technology utilized in Rexroth systems allows them to interface smoothly with other industrial technologies, providing a holistic approach to process automation and control. This integration facilitates real-time monitoring, allowing for proactive adjustments and ensuring optimal operational conditions.

In contemporary industrial settings, automation and robotics are key drivers of productivity. 4Wrd Rexroth plays a crucial role in this evolution by providing sophisticated solutions that optimize motion control. The technology serves diverse sectors, from automotive to consumer electronics, facilitating faster and more accurate production processes. Its integration into manufacturing lines allows for smoother operations and minimizes downtime through its robust design. The adaptability of Rexroth systems permits users to upgrade their existing workflows, aligning with the evolving trends in the workforce and technological advancements. This means that businesses are not only able to keep pace with competition but also remain agile in the face of rapidly changing consumer demands.

Industries from automotive to aerospace have adopted 4Wrd Rexroth solutions due to their reliability and adaptability. In the automotive industry, for instance, they contribute to precision tasks such as assembly and material handling. The aerospace sector benefits from the enhanced accuracy and control that Rexroth systems provide, ensuring safety and quality in production. Furthermore, sectors like pharmaceuticals are incorporating 4Wrd Rexroth systems to ensure compliance with regulatory standards while maintaining high productivity levels. The stringent requirements for contamination control in pharmaceutical manufacturing make Rexroth systems a favored choice due to their precision and robust design.

One notable use case is in the production of electric vehicles (EVs), where Rexroth motion control systems are being deployed to assemble battery packs with remarkable precision. The importance of battery assembly in electric vehicles cannot be overstated, and the 4Wrd Rexroth technology ensures that each component is fitted correctly, thereby reducing the risk of failures and enhancing vehicle reliability. In addition, the consumer electronics sector benefits from Rexroth’s capability to handle delicate components with the necessary finesse during assembly processes, ensuring high-quality products while minimizing the risk of damage to sensitive parts.

| Feature | 4Wrd Rexroth | Competitor A | Competitor B |

|---|---|---|---|

| Precision | High | Moderate | High |

| Adaptability | Extensive | Limited | Moderate |

| Maintenance | Low Requirement | High Requirement | Moderate Requirement |

| Cost Efficiency | High Long-Term | Moderate | High Initial |

| Integration Complexity | Minimal | High | Moderate |

| Support and Training | Comprehensive | Limited | Variable |

The successful implementation of 4Wrd Rexroth technology requires careful planning and understanding of the specific needs of the production line. Here’s a step-by-step guide to integrating this system into your operations:

To harness the full potential of 4Wrd Rexroth technology, businesses should consider integrating it with other advanced industrial technologies. For instance, combining Rexroth systems with Artificial Intelligence (AI) can enhance predictive maintenance, allowing systems to inform operators about potential failures based on historical data. Furthermore, incorporating IoT (Internet of Things) devices can provide real-time data analytics, enabling manufacturers to fine-tune operations based on current performance metrics. This integration leads to a more interconnected production environment, facilitating data-driven decision-making that significantly boosts productivity.

To better appreciate the capabilities of 4Wrd Rexroth, let's examine real-world implementations:

In an automotive plant, the integration of Rexroth's 4Wrd technology allowed for the automation of assembly tasks that were previously performed manually. By utilizing advanced motion control systems, the company achieved a reduction in assembly time by 30%. The precise coordination of robotic arms and conveyor systems resulted in a significant boost in productivity and a decrease in labor costs. Additionally, the consistency in quality improved, leading to fewer defects and greater customer satisfaction.

A leading pharmaceutical manufacturer implemented 4Wrd Rexroth systems to enhance the accuracy of filling and packaging processes. The result was an increase in compliance with stringent regulatory standards while also maximizing production efficiency. With the Rexroth technology, the facility managed to achieve a 25% decrease in waste due to inaccurate fills and a 40% improvement in overall production speed, demonstrating the system's effectiveness in high-stakes environments where precision is imperative.

What makes 4Wrd Rexroth unique compared to its competitors?

Its precision, adaptability, and low maintenance needs set it apart from others, providing superior control and efficiency. The focus on customization also ensures that each system is designed to meet the specific challenges faced by different industries.

How does 4Wrd Rexroth improve production line efficiency?

By reducing cycle times and enhancing resource utilization, it significantly boosts throughput and minimizes operational disruptions. Moreover, its capability to integrate with existing systems means that businesses do not have to overhaul their entire processes to achieve these improvements.

Is 4Wrd Rexroth suitable for small-scale operations?

Absolutely. Its versatility allows it to be tailored for operations of any size, enhancing capabilities without excessive scaling costs. Small manufacturers can employ Rexroth technologies to streamline their processes effectively, resulting in a competitive edge in the market.

The evolution of 4Wrd Rexroth technology is closely tied to the broader trends in industrial automation. As industries increasingly embrace Industry 4.0 principles, the integration of smart technologies will become paramount. Enhanced collaboration between machines and humans through advanced interfaces will further streamline operations and improve resource management. Additionally, sustainability is becoming a focal point in manufacturing, driving the demand for energy-efficient systems. The ability of Rexroth’s technology to optimize energy consumption will play a significant role in helping companies meet their sustainability goals.

Looking forward, we can expect to see advancements in machine learning algorithms that enhance the functionality of 4Wrd Rexroth systems. These developments will lead to systems that can learn from their operational contexts and make real-time adjustments to improve efficiency and precision further. Furthermore, the proliferation of edge computing will enable localized processing of data, leading to faster decision-making and reduced latency. As these trends continue to shape industrial automation, Rexroth's commitment to innovation will ensure its products remain at the cutting edge of technology.

The strategic integration of 4Wrd Rexroth technology into industrial settings is a forward-looking approach to bolstering performance and efficiency. As industries continue to embrace automation and robotic solutions, systems like Rexroth's are playing an increasingly pivotal role in shaping the future of manufacturing. By focusing on precision, adaptability, and technological integration, Rexroth stands ready to support the evolving needs of modern industries. As the landscape of industrial automation grows more complex, those who leverage these advanced systems will be well-positioned to thrive in the face of challenges and seize new opportunities.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!