This article delves into the Rexroth Dz6dp2, a vital component in the hydraulic systems known for its efficiency in pressure management. As part of the well-regarded Rexroth lineup, these components are designed to enhance performance in industrial applications. Explore the functions, benefits, and integration techniques of the Rexroth Dz6dp2 to optimize hydraulic systems effectively.

The Rexroth Dz6dp2 is a key player in the world of industrial hydraulics, offering precision and reliability for a variety of applications. Known for its robust construction and adaptability, this component is pivotal in systems where precise pressure control is paramount. The ability to function effectively under various environmental conditions makes the Rexroth Dz6dp2 a top choice among engineers and engineers alike, ensuring that machinery operates efficiently and maintains longevity.

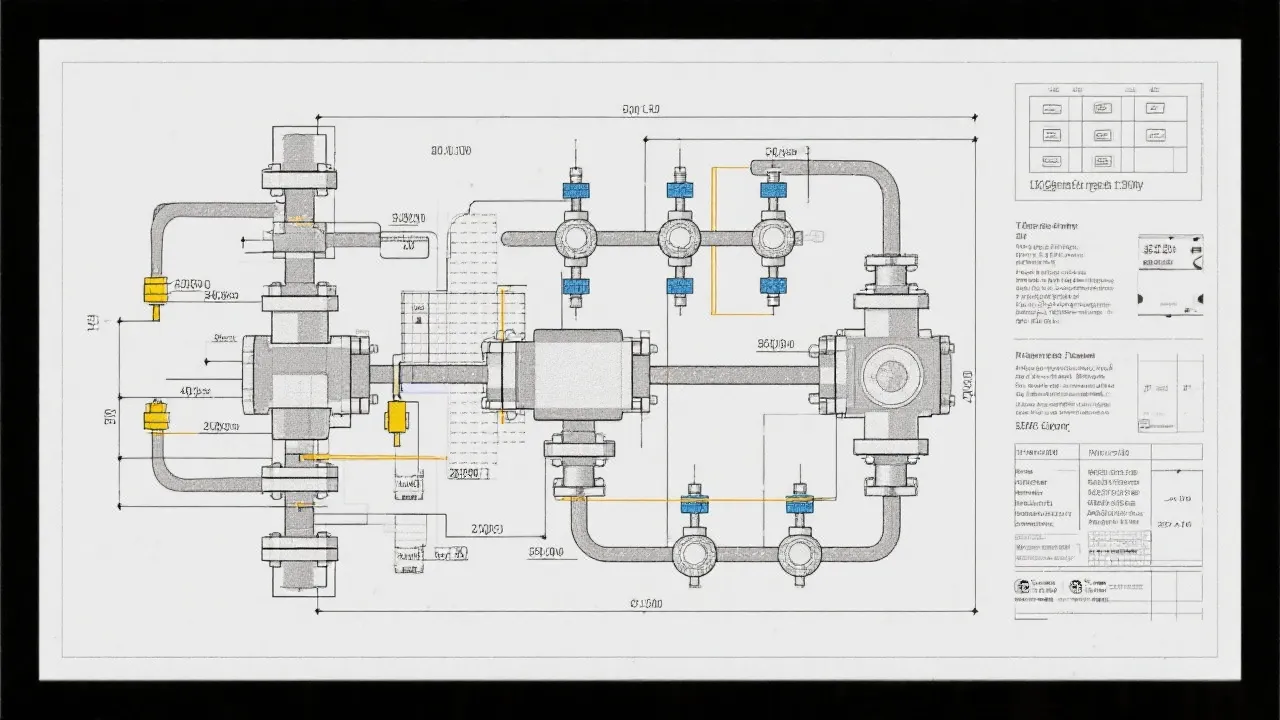

Hydraulic systems are the backbone of many industrial applications, from manufacturing to large-scale construction equipment. Within these intricate systems, components like the Rexroth Dz6dp2 play an essential function by regulating fluid flow, managing pressure, and ensuring that machinery operates smoothly and safely. The performance of hydraulic systems largely hinges on the reliability and accuracy of their individual components, emphasizing the importance of using high-quality elements like the Dz6dp2. It is this precision in pressure management that allows complex machines to perform efficiently and reliably, thereby boosting productivity across various industries.

Hydraulic systems rely on the principles of fluid mechanics, where liquids are used to transmit power and perform mechanical work. In many cases, the Dz6dp2 acts as a pressure relief valve, protecting equipment from damaging pressure surges that can arise during operation. By allowing excess pressure to escape safely, this component prevents potential failures that could lead to costly downtime and repairs. Additionally, the ability to achieve rapid response times enhances overall system performance, contributing to faster cycle times in manufacturing processes.

The Rexroth Dz6dp2 is crafted with a focus on durability and precision. Its features include advanced pressure control mechanisms, compatibility with various hydraulic fluids, and an ergonomic design that facilitates easy integration into existing systems. These aspects make it a preferred choice for engineers seeking to maintain high standards of operational efficiency. Let's take a closer look at its enhanced features and their implications for hydraulic systems.

For those in search of the Rexroth Dz6dp2, it is widely available through authorized distributors and suppliers of hydraulic components. Major industrial supply houses and specialized hydraulic distributors often stock this component, given its popularity and demand. Potential buyers should verify supplier credentials to ensure they receive genuine and high-quality products, as the market can include counterfeit items masquerading as the original Rexroth engineering.

In addition to traditional retailers, many online platforms and e-commerce sites offer convenient purchasing options. However, it is crucial to prioritize reputable sellers who provide transparent information regarding product specifications and warranty conditions. Relying on established suppliers can often provide peace of mind and ensure that customers receive the full benefits of product longevity and support.

Integrating the Rexroth Dz6dp2 into a hydraulic system should be approached with precision and care to fully leverage its capabilities. Proper alignment, secure fitting, and routine maintenance checks are essential steps in ensuring that the component performs optimally and extends the lifespan of the entire system. A well-executed installation includes a thorough review of the existing hydraulic design, ensuring compatibility with other components, and considering the overall flow dynamics within the system.

The installation process may involve the following steps:

Routine maintenance checks should involve not only visual inspections of the Dz6dp2 but also testing its performance under varying operational conditions. Ensuring that it continues to meet the prescribed pressure levels will aid in spotting potential issues before they escalate into serious failures.

The longevity of the Rexroth Dz6dp2 can be significantly enhanced by following a set of best practices for maintenance. A proactive maintenance approach entails regular inspections, making necessary adjustments, and promptly addressing any issues that may arise. Below are several recommended practices to keep the Dz6dp2 in optimal condition:

While the Rexroth Dz6dp2 is primarily known for its role in standard hydraulic systems, its versatility allows for adaptation in several specialized applications. Some notable uses include:

Its precision engineering, coupled with durability, makes it an ideal choice for maintaining efficient and reliable hydraulic operations. It withstands harsh industrial conditions while ensuring accurate pressure management.

While designed for industrial settings, its versatility allows for adaptation in some non-industrial contexts where hydraulic systems are implemented, such as in automotive or agricultural applications.

Regular inspections and servicing based on the manufacturer's recommendations are essential to keep the component functioning properly. Typically, these checks should be conducted at least once a quarter, or more frequently in high-usage scenarios.

A drop in performance may indicate wear or the need for adjustments. First, check for leaks or blockages in the hydraulic lines. If performance issues persist, consult the manufacturer's guidance or contact a qualified technician for a thorough inspection.

In conclusion, the Rexroth Dz6dp2 serves as an impressive piece of hydraulic engineering, aiding in the precision, efficiency, and safety of complex industrial processes. Its robust design, operational excellence, and adaptable applications are testaments to Rexroth’s commitment to quality and performance. Understanding the intricacies of this component not only assists in proper integration and maintenance but also highlights its extensive potential across various industries, making it an invaluable element in modern hydraulic technology.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!