This comprehensive guide explores the intricacies of Dbds Rexroth systems, a well-respected name in hydraulic valve components. Known for their innovative design and performance efficiency, Dbds Rexroth products are pivotal in various industries, including manufacturing and automation, enhancing precision and reliability.

Dbds Rexroth systems represent the pinnacle of hydraulic technology, renowned for their ability to transform industrial operations with precision and reliability. These systems are integral to the manufacturing, automation, and construction sectors, offering unmatched performance in controlling hydraulic fluids. With their precision and reliability, Dbds Rexroth systems are not just a tool; they are a critical component that underpins modern manufacturing and processing techniques, enabling a more efficient approach in industries that rely heavily on hydraulic systems. By enhancing efficiency and ensuring stable operation across various applications, Dbds Rexroth systems establish themselves as a leader in hydraulic technology.

The Dbds Rexroth suite encompasses hydraulic valves designed for dynamic applications. Their primary role is to regulate the flow of hydraulic fluid, ensuring optimal performance across various mechanisms. Using high-strength materials and innovative design, these valves maintain their functionality under high-pressure conditions, which is essential for maintaining system reliability. Additionally, the integration of advanced materials helps in enhancing the lifespan of the components. Dbds Rexroth systems are lauded for their durability and efficiency, making them essential in today's modern industrial applications. Their impact is felt not only in the functionality of machines but also in their ability to contribute to economic efficiency through reduced operational costs and downtime.

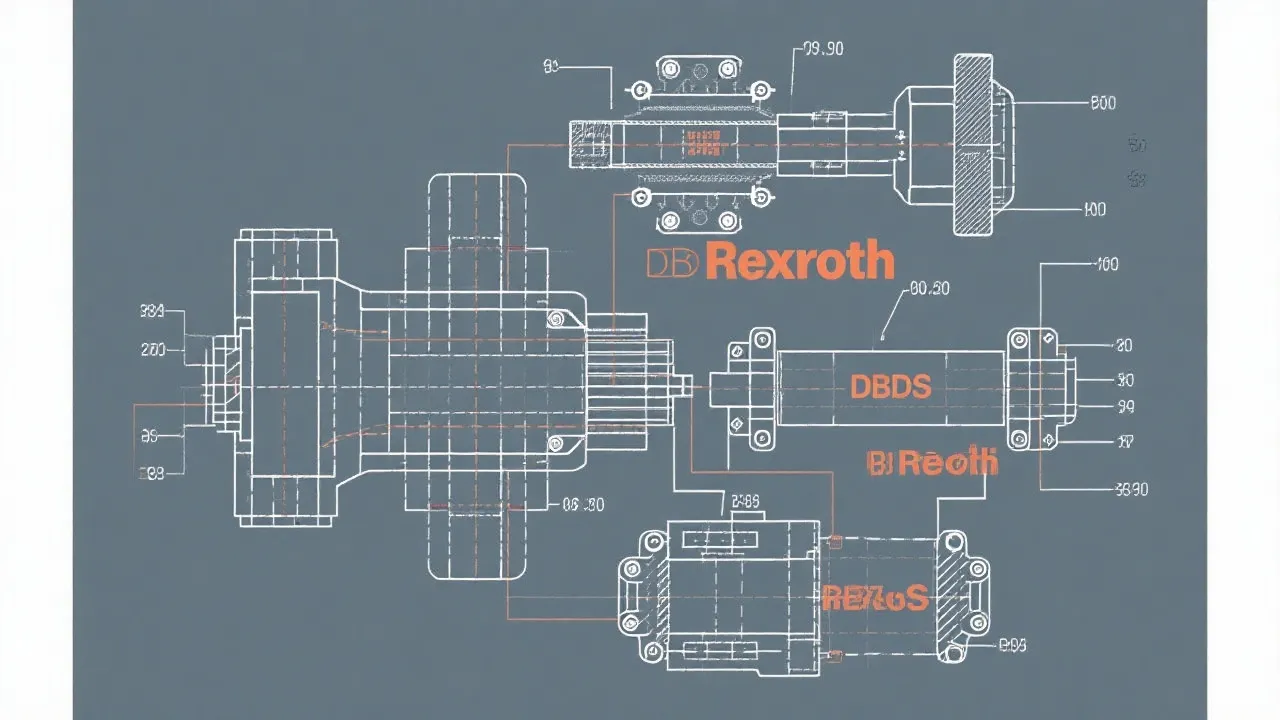

The core components of Dbds Rexroth valves include spools, housings, and actuators, each contributing to the precise control of fluid dynamics. Spools within the valve dictate flow direction, determining how fluid moves through the system. This functionality is critical in applications that require specific flow patterns to achieve desired operational outputs. The housing, made from durable materials, provides structural integrity and protects the internal components from external pressures and contaminants. Actuators manage the valve operation, optimizing fluid routing to meet specific operational needs. Advanced actuator technologies, including electric and hydraulic actuation methods, further enhance precision, allowing for quicker and more reliable valve adjustments, thereby increasing the overall responsiveness of the system. Through these components, Dbds Rexroth systems exemplify the model of modern hydraulic systems, where each part is designed to work in harmony with the others for optimal performance.

Recent technological advancements have enhanced the functionalities of Dbds Rexroth valves. These systems now incorporate electronic controls for improved precision. Digital feedback loops allow for real-time adjustments, significantly enhancing the responsiveness and efficiency of hydraulic applications. The integration of sensors that monitor flow rate, temperature, and pressure ensures that any anomalies can be detected and addressed immediately, increasing safety and reliability in operations. Furthermore, advancements in materials science have led to the development of components that can operate in harsher environments, such as those involving high temperatures or corrosive fluids. This resilience is crucial for industries that push the boundaries of standard operating conditions, such as oil and gas, mining, and pulp and paper. As a result, Dbds Rexroth systems can be configured for a wide range of applications, from simple tasks to the most complex and demanding hydraulic circuits.

Implementing Dbds Rexroth systems can lead to several benefits, including enhanced energy efficiency, reduced operational costs, and increased system lifespan. Their robust design minimizes the risk of leaks and mechanical failures, providing reliable performance under extreme conditions. The energy-efficient designs of Dbds Rexroth systems reduce the overall energy consumption of hydraulic machines, leading to substantial cost savings in energy bills over time. Moreover, lowering energy usage also contributes to a reduced carbon footprint, aligning with global sustainability efforts. Utilizing advanced electronic controls and sophisticated algorithms, these systems optimize hydraulic flow dynamics, ensuring that power is used precisely as needed. This level of control means that not only are resources conserved, but the operational efficiency is maximized as well—substantially reducing waste in the production process and further solidifying the economic advantages of adopting Dbds Rexroth technology. Additionally, the durability and reliability of these components can translate into lower long-term maintenance costs, as fewer replacements and repairs are needed over the lifespan of the machinery.

| Feature | Dbds Rexroth | Competitors |

|---|---|---|

| Precision | High precision with adaptive controls that adjust automatically based on system parameters. | Varies, generally less advanced controls with manual adjustments. |

| Durability | Extremely robust materials and design for high-pressure and demanding environments. | Medium to high durability; some brands may lack resilience in extreme conditions. |

| Energy Efficiency | Optimized for low energy consumption with innovative designs that minimize waste. | Varies, often higher energy usage, leading to increased operational costs over time. |

| Controls | Advanced electronic controls with real-time monitoring and adjustments. | Limited capabilities; often rely on basic mechanical or pneumatic systems. |

As industries worldwide increasingly lean towards automation, numerous real-world applications have demonstrated the effectiveness of Dbds Rexroth systems. A case study in the automotive sector showcases how a manufacturer improved their assembly line efficiency by integrating Dbds Rexroth technology. The implementation of these hydraulic systems allowed for precise control of robotic arms used in material handling, resulting in a 30% increase in throughput while simultaneously reducing energy costs by 25%. This improvement not only enhanced production efficiency but also significantly cut down on waste and operational downtime.

Another compelling example comes from the construction industry, where a large construction firm adopted Dbds Rexroth hydraulic systems for their excavators and cranes. By utilizing these advanced hydraulic controls, the firm achieved better load handling and increased the overall speed of lifting operations. The result was a decrease in project timelines by several weeks, ultimately leading to substantial savings. Additionally, the durable design of Dbds Rexroth components ensured that the machinery operated reliably under harsh conditions, which is often a challenge on construction sites.

Looking ahead, the future of hydraulic technology is set to experience incredible innovation, particularly as industries strive for greater efficiency and integrate more automation into their operations. IoT-enabled hydraulic components will soon become more commonplace, allowing for predictive maintenance and more intelligent systems. By leveraging data analytics and machine learning, operators will be able to anticipate failures before they occur, reducing downtime and maintenance costs significantly.

Furthermore, there is a growing trend towards the development of fully electric hydraulic systems, which operate with increased efficiency and significantly lower environmental impact. These systems utilize various technologies, including electric motor pumps that reduce reliance on traditional hydraulic fluids without sacrificing power. As sustainability becomes a primary focus across industries, Dbds Rexroth and other manufacturers are likely to continue innovating solutions that meet both operational needs and environmental regulations.

Dbds Rexroth systems redefine hydraulic controls with a blend of precision engineering and innovative technology. As industries strive for efficiency and precision, these systems offer a reliable solution, heralding a new era in hydraulic applications. Embracing Dbds Rexroth systems marks a significant step towards optimized operational standards and sustainable industrial practices. Coupled with ongoing advancements in technology, the future seems promising for hydraulic systems as they evolve to meet the ever-increasing demands of modern industries. With their commitment to quality, efficiency, and longevity, Dbds Rexroth stands as a testament to the advances in fluid control technology, ensuring that businesses not only thrive today but are also well-prepared for the challenges of tomorrow.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!