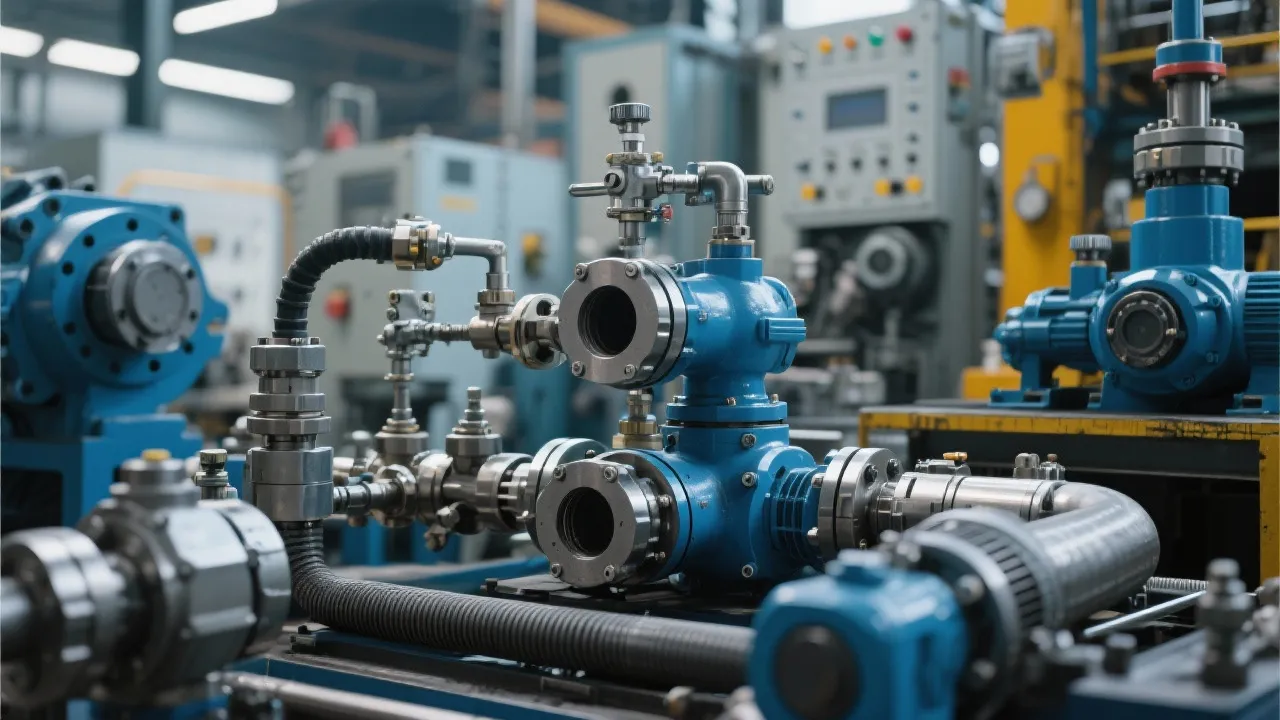

The core of this article revolves around the 2frm Rexroth, a key player in hydraulic technology. Known for its precision and efficiency, the 2frm Rexroth powers diverse machinery across various industries. This article delves into the specifics of its components, versatility, and optimal applications, offering a thorough expert analysis for industry professionals seeking to enhance system performance.

The 2frm Rexroth system is a pivotal component within the realm of hydraulic technology, recognized for its precision and durability. It is frequently employed to enhance the efficiency and operability of industrial machinery. This hydraulic component stands as a testament to engineering advancement, utilized in numerous sectors where precision, reliability, and performance are paramount. The innovative design and robust construction of the 2frm Rexroth system make it a preferential choice among engineers and technicians, particularly in environments where high hydraulic pressures are commonplace. Over the years, further advancements in its technology have contributed to an ever-increasing range of applications, solidifying its position as a cornerstone in the field of fluid power systems.

The adaptability of the 2frm Rexroth is one of its standout features. It is integral in machines that require adept handling of hydraulic pressure for optimized function. Its application ranges from construction equipment to manufacturing machinery, evidencing its integral role in industry-specific processes that depend on accurate pressure control for effective operation. For instance, in construction, hydraulic systems equipped with 2frm Rexroth components facilitate various tasks, such as lifting, moving, and shaping materials with unparalleled accuracy and efficiency. In manufacturing settings, these systems allow for the automation of repetitive tasks, drastically increasing production rates while ensuring high-quality output.

This adaptability also extends to integrating with various machine architectures, contributing significantly to customizing machinery to suit specific operational requirements. As industries evolve and technology progresses, the versatility of the 2frm Rexroth ensures that it remains relevant across various applications, whether in robotics, agricultural machinery, or advanced manufacturing processes. The ability to seamlessly integrate with IoT devices and smart factory solutions further enhances its value, enabling real-time monitoring and predictive maintenance strategies that keep systems running smoothly.

Designed with cutting-edge engineering, the 2frm Rexroth offers numerous advantages in terms of hydraulic control. Among its notable features are robust pressure management and a compact design, which collectively ensure minimum downtime and maximum output efficiency. Moreover, its durability under varying operational conditions enhances its appeal to industries that demand relentless performance. The 2frm Rexroth system incorporates advanced materials and manufacturing processes that enhance its strength and resistance to wear and tear, which is a critical requirement in environments exposed to harsh conditions.

Another key feature is the system's ability to maintain stable performance across a wide temperature range, making it suitable for outdoor applications or environments with fluctuating temperatures. The hydraulic components within the 2frm Rexroth are specifically engineered to minimize fluid leakages, reducing maintenance needs and contributing to environmental sustainability by diminishing potential fluid contamination issues. Additionally, the ease with which the components can be assembled and disassembled significantly reduces the time and labor associated with installation and maintenance, further enhancing operational efficiency.

2frm Rexroth systems find applications across various sectors, with significant prominence in construction, manufacturing, and automation industries. Its integration into these fields speaks to its design flexibility and dependability. Specialists in these industries commend the component's ability to consistently deliver under heavy-duty operational scenarios. For instance, in the automotive sector, manufacturers utilize 2frm Rexroth hydraulics to manage assembly processes, improving accuracy in the assembly line while enhancing productivity rates.

In the realm of agricultural technology, 2frm Rexroth systems are found in equipment such as tractors and harvesters, where they operate critical functions including steering systems, hydraulic lifts, and auxiliary attachments with precision and reliability. The adaptability of 2frm Rexroth components allows them to adjust to the varying demands of agricultural processes, enhancing productivity in the field.

Automation industries also significantly benefit from the integration of 2frm Rexroth systems. With the rise of smart manufacturing, the capability to connect and control hydraulics through digital platforms is vital. 2frm Rexroth not only serves traditional hydraulic functions but is also adaptable to fit into modern technology paradigms, facilitating smooth transitions from manual to automated processes.

| Aspect | 2frm Rexroth | Equivalent Products |

|---|---|---|

| Pressure Capacity | Up to 350 bar | Averages 250-300 bar |

| Efficiency | High | Medium |

| Key Industries | Automation, Construction, Agriculture | General Manufacturing, Mining |

| Temperature Range | -20°C to +80°C | -10°C to +70°C |

| Fluid Compatibility | Wide range of hydraulic fluids | Standard hydraulic fluids |

Proven in empirical studies and real-world implementations, the 2frm Rexroth system has delivered noticeable improvements in operational efficiency and system longevity. Companies have reported substantial reductions in maintenance costs and downtime since integrating the system, highlighting its economic benefit alongside its technical efficacy. In one case study, a leading construction firm utilizing 2frm Rexroth components in its heavy machinery reported a 30% increase in operational efficiency, allowing for quicker project turnaround times and enhanced profitability.

Another compelling example can be seen in a manufacturing facility that employed the 2frm Rexroth system in their robotic assembly lines. They observed a dramatic decrease in the frequency of machinery failure, coupled with a 25% reduction in energy consumption, which directly impacted their operational costs positively. The tangible benefits gained from implementing the 2frm Rexroth have led many companies to prioritize this technology in their machinery selection processes.

Furthermore, industries that require compliance with strict environmental regulations have embraced 2frm Rexroth for its sustainable design and reduced leakage, which contribute to lower instances of environmental contamination. Companies seeking to enhance their green credentials have found the 2frm Rexroth systems not only beneficial but essential in achieving their sustainability goals.

For ensuring optimal performance, routine checks and maintenance of the 2frm Rexroth are recommended. Regular inspections and calibration are essential to mitigate performance degradation over time. Adhering strictly to the manufacturer's servicing guidelines will extend the component's lifecycle, safeguarding machinery from potential inefficiencies.

Operators should be trained to monitor system performance actively; sensors can provide valuable data regarding fluid levels, pressure stability, and temperature fluctuations. Utilizing diagnostic tools to analyze performance metrics will assist in identifying potential issues before they result in system failure. Further, lubricating moving parts and ensuring cleanliness around hydraulic connections can significantly minimize wear and prolong the lifespan of the 2frm Rexroth components.

Moreover, preventative maintenance should be coupled with a thorough training program for personnel. Employees familiar with the intricacies of the 2frm Rexroth system will be better equipped to handle troubleshooting and may even provide innovative solutions for operational enhancement. Engaging with user communities and forums can also serve as a valuable resource for operators looking to optimize the application of 2frm Rexroth systems in their respective fields.

Q1: What are the primary industries using 2frm Rexroth systems?

A1: Predominantly, the construction, manufacturing, and automation sectors utilize 2frm Rexroth systems for their robust performance, whereas agriculture is emerging as a significant sector benefiting from this technology.

Q2: How does the 2frm Rexroth improve machinery efficiency?

A2: Through precise pressure control and a compact design, the 2frm Rexroth enhances machinery efficiency by ensuring reliable performance under demanding conditions, allowing machines to operate at their optimal capacity.

Q3: What routine maintenance practices are recommended?

A3: Regular inspections and pressure calibrations are advised, following the manufacturer's guidelines, along with lubricating moving parts and ensuring cleanliness are crucial for maintaining optimal function and extending the component's operational life.

Q4: Can 2frm Rexroth systems be integrated into existing machinery?

A4: Yes, one of the primary advantages of the 2frm Rexroth system is its adaptability. It can often be retrofitted into existing systems, making it a versatile choice for upgrades and modernization projects.

Q5: Are 2frm Rexroth components environmentally friendly?

A5: Yes, 2frm Rexroth components are designed to minimize leakage and energy consumption, aligning with the increasing demand for environmentally sustainable engineering solutions.

The 2frm Rexroth embodies a synthesis of advanced engineering and efficiency. This article highlights its widespread applications, advantages, and maintenance protocols, providing a comprehensive view for professionals seeking reliable hydraulic solutions in demanding operational landscapes. As industries continue to evolve towards smart, interconnected systems, the relevance and application of the 2frm Rexroth system are poised to grow significantly in line with these technological advancements.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!