This article delves into the intricate details of the 110len Rexroth, a vital component used in various industrial applications. Known for its reliability and efficiency, this piece serves industries worldwide where efficient hydraulic systems are critical. Understanding its specifications and applications can greatly enhance operational productivity and mechanical performance.

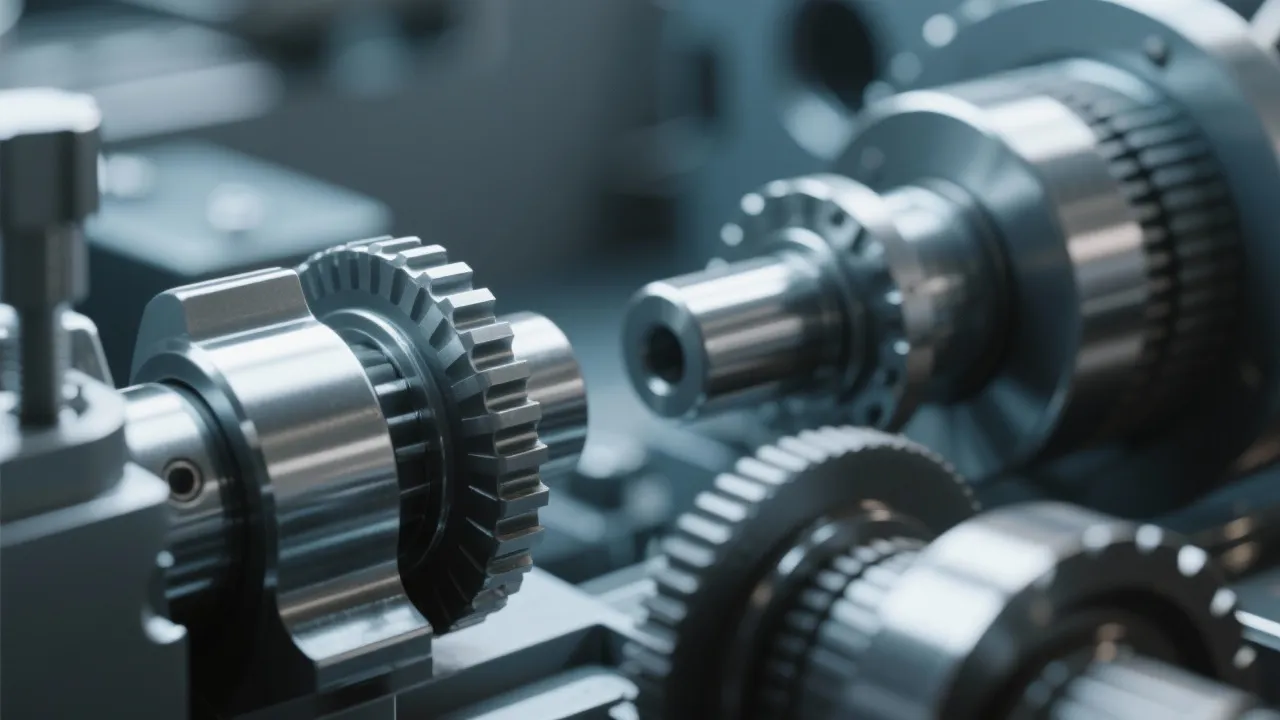

The 110len Rexroth emerges as an essential component in the world of industrial machinery and hydraulic systems. Recognized for its precision and durability, the 110len Rexroth offers formidable performance, particularly in high-demand environments where efficiency and reliability are paramount. This article provides an in-depth exploration of its characteristics, applications, and comparative advantages.

Hydraulics is a critical field that harnesses the power of pressurized fluids to perform work. The 110len Rexroth demonstrates this principle effectively by leveraging advanced hydraulic technology to meet the needs of various industrial applications. Created by Bosch Rexroth, a leader in drive and control technology, the 110len Rexroth is designed to operate smoothly under extreme conditions, making it a trusted choice among engineers and operators alike. Information on its applications, maintenance, and specific features highlight its status as an industry staple.

The 110len Rexroth encompasses a variety of features that make it suitable for a wide range of applications. Offering advanced hydraulic control, it integrates seamlessly into existing systems, enhancing overall functionality. Its robust design ensures longevity, even under strenuous conditions. The component's specifications typically include features such as integrated pressure relief valves, adjustable flow settings, and compatibility with various fluid types, making it adaptable to numerous industrial requirements.

In addition to its core features, the 110len Rexroth is engineered with proprietary technology that enhances its overall durability. The materials used in its construction include advanced alloys that resist wear and corrosion, ensuring that the components maintain their integrity over extended use. The seals employed within the system are crafted to prevent leaks, a common issue in hydraulic systems that can lead to catastrophic failures if not addressed. Moreover, its compact design allows for easier integration into tight spaces, thus widening its usability in bespoke machinery designs.

The hydraulic components are often rated for varying pressure ranges, with the 110len Rexroth typically accommodating pressures up to several thousand psi. This makes it suitable for applications requiring significant force, such as metal forming or heavy lifting operations. Additionally, the system is designed for energy efficiency; it minimizes hydraulic fluid loss and maximizes the transfer of power, contributing to overall machine efficiency. Users can specify their requirements, tailoring the 110len Rexroth to their particular operational contexts.

The versatility of the 110len Rexroth allows it to be utilized across multiple sectors. Commonly implemented in construction machinery, these components are pivotal in optimizing the hydraulic functions of excavators, cranes, and loaders. Additionally, the manufacturing sector finds the Rexroth crucial for machines that require consistent force and precision, such as injection molding machines and automated assembly lines.

Furthermore, the agriculture sector has embraced the 110len Rexroth to improve the performance of various farming equipment, including tractors and hydraulic implements like sprayers and seeders. Its ability to function reliably in outdoor and dusty environments ensures that agricultural operations can run smoothly without unexpected failures.

In the marine industry, the 110len Rexroth serves vital functions, including steering systems on larger vessels and controlling heavy machinery used in shipbuilding and repair. Its resilience against environmental factors, including moisture and salinity, allows operators to maintain consistent performance in challenging offshore environments. Additionally, the energy sector employs the 110len Rexroth in wind turbines and other renewable energy applications where precision-controlled hydraulics play a pivotal role in the generation of energy.

In contrast to its competitors, the 110len Rexroth offers a unique blend of reliability and technological advancement. While alternatives may offer savings in cost, the superior build quality and sustained performance of Rexroth components often result in better good value. Below is a table highlighting key differences:

| Feature | 110len Rexroth | Competitor A | Competitor B |

|---|---|---|---|

| Durability | High | Medium | Low |

| Performance | Consistent | Variable | Inconsistent |

| Cost Efficiency | High | Low | Medium |

When assessing durability, the 110len Rexroth clearly stands out due to its higher resistance to wear and tear compared to its competitors. While some rivals may offer lower-priced components, this often comes at the expense of material quality and the longevity of the product. As a result, maintenance costs and downtime can increase over the lifespan of machinery utilizing lower-quality parts.

Performance is another critical differentiation point. The 110len Rexroth demonstrates consistent output across various applications, providing users with predictable and reliable operation. This consistency is vital for industries where even minor fluctuations can lead to significant problems down the line, such as product defects or safety issues.

Regular maintenance is crucial to maximizing the lifespan of the 110len Rexroth. Maintenance tasks should include regular inspections, pressure checks, and ensuring compatibility with hydraulic fluids. Continuous monitoring can prevent common issues such as leaks or pressure drops, thus ensuring sustained efficiency and performance.

A proactive approach to maintenance can significantly extend the life of the 110len Rexroth. Operators are encouraged to implement a routine schedule for inspections and servicing. This includes checking fluid levels, assessing the integrity of hoses and connections, and replacing any worn-out seals or filters as needed. Keeping an eye on the operational parameters—such as temperature and pressure—can also preemptively highlight potential issues before they escalate into costly repairs.

Furthermore, it's important to educate operators and maintenance personnel about the specific nuances and requirements of the 110len Rexroth. Understanding how the system works and knowing the symptoms of potential failures can aid in prompt troubleshooting and intervention. Documentation providing guidelines on proper usage and maintenance practices can assist in ensuring that every technician is well-equipped to handle issues as they arise.

Q1: What industries benefit the very from 110len Rexroth?

A1: Industries such as construction, manufacturing, and agriculture see significant benefits from using 110len Rexroth due to its reliable hydraulic control capabilities.

Q2: How does the 110len Rexroth improve operational efficiency?

A2: It improves efficiency by providing precise control over hydraulic functions, resulting in smoother and more reliable machine operation.

Q3: Are there any specific maintenance tips for longevity?

A3: Regular maintenance, including fluid checks and component inspections, will help preserve the functionality and prolong the life of the Rexroth components.

Q4: Can the 110len Rexroth be customized for specific applications?

A4: Yes, the 110len Rexroth is highly customizable, allowing manufacturers to specify configurations that suit their precise operational requirements based on load, pressure, and application needs.

Q5: What types of fluids are compatible with the 110len Rexroth?

A5: The 110len Rexroth is compatible with various hydraulic fluids, including mineral oils, biologically degradable oils, and water-containing fluids, making it flexible for diverse operational scenarios.

The 110len Rexroth stands out as a premium choice for industries demanding precision and robust performance in their hydraulic systems. Its unique attribute of blending cutting-edge technology with exceptional durability makes it a valuable asset, ensuring long-lasting efficiency and optimized operational functionality.

In conclusion, the 110len Rexroth is not merely a component; it represents a commitment to innovation, quality, and performance that resonates across industries. Companies investing in such high-performance systems often find their operational reliability and productivity enhanced, translating into improved bottom lines and competitive advantages in their respective markets. As industrial applications continue to evolve, components like the 110len Rexroth will be key players in driving progress and efficiency in an increasingly demanding landscape.

Looking ahead, the future of hydraulic technology is poised to be shaped significantly by advancements in automation and smart technologies. With the rise of Industry 4.0, intelligent systems are being increasingly integrated into hydraulic components like the 110len Rexroth. These advancements could include the ability to gather data in real-time, enabling predictive maintenance, which can significantly reduce downtime and maintenance costs.

Furthermore, sustainability is becoming a crucial focus in the development of hydraulic systems. Manufacturers are looking into ways to create more eco-friendly hydraulic fluids and components that minimize environmental impact while maintaining or improving performance. The 110len Rexroth, with its emphasis on efficiency and durability, is well-positioned to adapt to these changing demands, continuing its legacy as a leader in hydraulic technology.

Moreover, as industries look towards resilience and adaptability in their operations, components that can easily integrate with new technologies will become crucial. The ability of the 110len Rexroth to work seamlessly with varying types of hydraulic fluids and its compatibility with automated systems place it at the forefront of this transition, making it an indispensable asset for future industrial applications.

In summary, the 110len Rexroth exemplifies not only high-quality engineering but also a forward-thinking approach that embraces both technological advancements and sustainability principles. This positions it not only as a reliable choice for today's challenges but also as a versatile solution for the future of hydraulic systems across industries.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!