The 4wmm Rexroth system represents a key facet of hydraulic technologies utilized across various industrial applications. Known for their innovation and reliability, Rexroth components are integral to optimizing machinery performance. As industries increasingly adopt automation and precision engineering, understanding the nuances of systems like the 4wmm Rexroth becomes crucial for achieving operational efficiency.

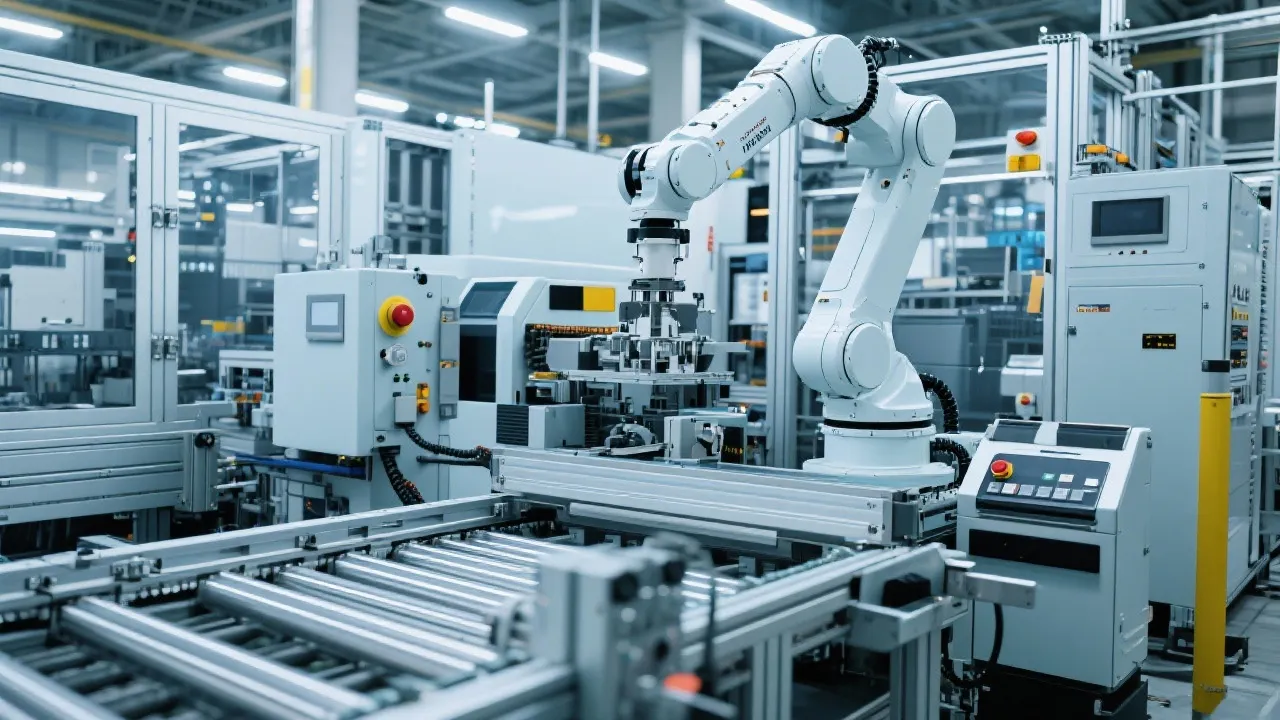

The 4wmm Rexroth refers to a series of hydraulic directional control valves by Bosch Rexroth, a leader in drive and control technologies. Recognized for their precision and adaptability, these components are essential in a variety of industrial applications, ranging from manufacturing and automotive to marine and mobile machinery. Designed to manage and control fluid flow, these valves are instrumental in driving efficiency and reliability in complex systems. The 4wmm series stands out due to its unique modular design, which allows for easy configuration and installation, making it a preferred choice for many engineers and technicians. In addition to their functionality in various environments, they are increasingly utilized in automated systems, where precise control over hydraulic fluid is paramount.

Hydraulic systems are critical in transforming mechanical energy into hydraulic energy, a crucial process in modern industrial operations. These systems use a liquid, usually oil, to transmit power efficiently across various components. The basic premise of hydraulic systems is governed by Pascal's principle, which states that pressure applied to a confined fluid is transmitted undiminished in all directions throughout the fluid. This principle forms the foundation of how hydraulic machinery operates and how energy is transmitted and controlled. The 4wmm Rexroth valves play an essential role in directing the flow of hydraulic fluid, which ultimately controls the speed, direction, and force of actuators and motors within machinery. Their implementation helps achieve smoother and more predictable motion, essential for applications in robotics, construction machinery, and material handling systems.

| Feature | 4wmm Rexroth | Other Brands |

|---|---|---|

| Precision | High precision with minimal deviation | Varies, often less precise |

| Material Quality | Top grade, corrosion-resistant materials | Mixed, often lower grades |

| Application Range | Extensive, from industrial to mobile applications | Limited to specific areas |

| Design Flexibility | Modular and customizable | Less adaptable to custom configurations |

| Electronic Integration | Compatible with advanced control systems | Often limited integration options |

Implementing Rexroth hydraulic valves transforms how machinery functions by improving accuracy, safety, and performance. The ability to control fluid flow precisely leads to enhanced machine responses, reducing waste and energy consumption. For instance, in applications such as injection molding, precise control over the hydraulic system can lead to better product quality and reduce material waste. Companies looking to enhance their engineering processes benefit from the integration of these valves, which also support sustainability initiatives through energy-efficient operations. Additionally, advanced diagnostics available with these valves facilitate easier troubleshooting and maintenance, which is crucial for minimizing downtime in industrial applications.

Regular maintenance is crucial to prolonging the lifespan and functionality of Rexroth valves. It's advised to periodically check for any wear and tear, keep components clean, and ensure they are operated within specified pressure ranges to prevent any failures. An effective maintenance schedule should include not only routine inspections but also testing of hydraulic fluid quality, as contaminants can lead to valve malfunctions. Moreover, lubricating the internal components can help maintain smooth operation. Conducting training sessions for operators on the importance and practices of maintenance ensures that the equipment is handled correctly and any potential issues are identified early. A proactive maintenance approach not only extends the service life of your Rexroth valves but also enhances overall productivity and safety within the facility.

Industry experts advocate for the use of 4wmm Rexroth for their superior engineering and economic advantages. With the growing trend towards automation, these valves represent a future-ready solution that integrates seamlessly with advanced control systems. Experts highlight the increasing demand for efficiency and precision in manufacturing processes, which aligns perfectly with the capabilities of Rexroth valves. Moreover, industry professionals emphasize the importance of investing in high-quality components like those from Rexroth, as they lead to significant cost savings in operations, reduce maintenance needs, and improve product quality. Harnessing the power of digital twins for simulation and planning further underlines how critical these valves can be in modern engineering practices, paving the way for innovations such as smart factory solutions.

Several businesses have successfully integrated 4wmm Rexroth valves into their operations, highlighting remarkable improvements in efficiency and reliability. One noteworthy instance is a large automotive manufacturer that adopted Rexroth valves in their assembly line. The shift resulted in a 30% reduction in cycle time due to improved hydraulic responsiveness, translating into significant financial savings. Furthermore, the precise flow control enabled by the valves led to higher quality standards in the final products, which is critical in the competitive automotive market.

Another case involved a construction equipment manufacturer that faced challenges with hydraulic system failures leading to increased downtime. By replacing their existing valves with 4wmm Rexroth units, they reported not only a decrease in maintenance interventions by 40% but also improved their load-handling capabilities. This transition proved essential in maintaining productivity during peak construction seasons, showcasing how strategic upgrades can yield substantial operational benefits.

In the current industrial landscape, sustainability is becoming increasingly crucial, both for regulatory compliance and corporate responsibility. Rexroth's commitment to creating energy-efficient hydraulic systems aligns perfectly with these goals. Utilizing 4wmm valves contributes to reduced energy consumption during operations and minimizes hydraulic fluid leaks, which are detrimental to the environment. By choosing high-quality and efficient components such as Rexroth, companies can comply with environmental standards while promoting a green manufacturing ethos.

Sustainable practices within hydraulic systems also extend to the lifecycle management of components. Implementing practices such as recycling old hydraulic fluid and responsibly disposing of replaced parts and materials significantly lessen the environmental impact. As industries continue to prioritize eco-friendly processes, companies that integrate solutions like the 4wmm Rexroth valves position themselves not only as leaders in technology but also as responsible stewards of the planet.

The 4wmm Rexroth series of hydraulic directional control valves represent a significant advancement in hydraulic engineering, offering unmatched precision, durability, and versatility. Their critical role in enhancing operational efficiency makes them indispensable in various industrial applications. By understanding and leveraging the capabilities of these valves, organizations can optimize their machinery, improve maintenance practices, and contribute to sustainable operations. As industries evolve and embrace more automated processes, investing in high-quality hydraulic components like the Rexroth 4wmm valves will be crucial for businesses looking to remain competitive and efficient in an ever-changing market landscape.

Looking forward, several trends in hydraulic technology indicate a promising future for the integration and use of hydraulic components like the 4wmm valves. One major trend is the ongoing shift towards automation and digitalization. With the rise of Industry 4.0, factories and machinery are becoming increasingly interconnected through the Internet of Things (IoT). This interconnectivity allows for real-time monitoring of machinery performance, predictive maintenance, and optimized workflows, thus enhancing productivity and reducing unforeseen downtimes.

Moreover, advancements in sensor technology and data analytics will empower engineers to make data-driven decisions, adjusting hydraulic systems with precision according to operational needs. Rexroth’s commitment to integrating smart technologies into their product lines ensures that their valves remain at the forefront of this evolution, evolving alongside industry requirements.

In addition, as the global emphasis on sustainability continues to intensify, hydraulic systems are adapting to requirements for reducing energy consumption and enhancing the performance of fluid dynamics. Research and development in new materials and synthetic fluids are also likely to impact the future of hydraulic components. Innovations in low-viscosity fluids could enhance energy efficiency while maintaining the necessary power output for high-performance applications.

In conclusion, the 4wmm Rexroth valves exemplify the cutting-edge of hydraulic technology, providing invaluable advantages for industries seeking to optimize their operational capabilities. As technology progresses, staying abreast of new advancements and best practices will be key for companies aiming to leverage the full potential of modern hydraulic systems. The relationship between effective hydraulic components and the overall performance of machinery cannot be understated, and organizations that prioritize these components will likely lead the way into the next era of industrial efficiency and effectiveness.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!