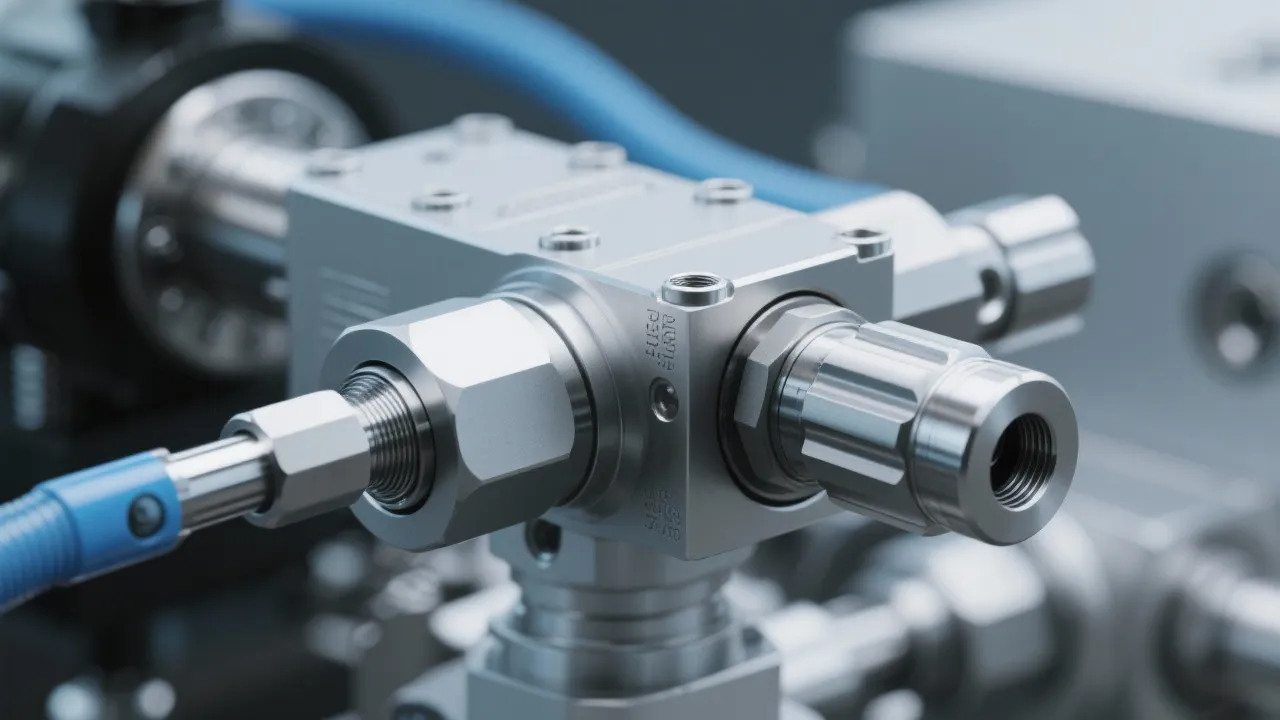

This guide offers a comprehensive look at the 4wmm Rexroth valve, a critical component in hydraulic systems renowned for its efficiency and precision. As an integral part of Bosch Rexroth's product portfolio, the 4wmm valve is lauded for its robust design and reliability, critical in diverse industrial applications from manufacturing to automation.

In the realm of hydraulic systems, the 4wmm Rexroth valve stands as a testament to engineering excellence and reliability. Manufactured by Bosch Rexroth, a leader in industrial technology and components, the 4wmm Rexroth valve has become synonymous with precision in motion control technology. This valve is essential in systems that demand high efficiency and precision, bridging complex mechanisms with ease.

As industries evolve and technological advancements push the limits of hydraulic applications, the need for high-performance components has never been more critical. The 4wmm Rexroth valve is designed to meet these challenges head-on, offering solutions tailored for both conventional and cutting-edge applications. From powering machinery on a construction site to facilitating energy-efficient automation in manufacturing plants, the 4wmm Rexroth valve plays a fundamental role in ensuring operational excellence.

Hydraulic systems owe much of their versatility and power to components like the 4wmm Rexroth valve. These valves play a pivotal role in altering the flow and direction of hydraulic fluid within a circuit, thus controlling the movement of components such as actuators and motors. Their application can be seen across various industries, including manufacturing, construction, and even automotive sectors, where precision and speed are paramount.

In the manufacturing industry, hydraulic systems are utilized for tasks such as material handling, press operations, and machine tool movements. The 4wmm Rexroth valve provides the precise control needed for these applications, ensuring that machinery operates efficiently and reliably. In construction, it aids in the operation of heavy machinery, such as excavators and cranes, where power and control must work in tandem to achieve safety and productivity. Furthermore, in automotive production lines, the 4wmm Rexroth valve contributes to assembly processes, enhancing the manufacturing cycle time while maintaining precision.

The importance of the 4wmm Rexroth valve extends beyond just control. It incorporates features that respond to the evolving needs of industries, such as the integration of digital technologies for enhanced monitoring and control. As factories adopt Industry 4.0 principles, the demand for smarter hydraulic solutions that can communicate and adapt to different conditions is increased, cementing the role of the 4wmm Rexroth in the future of hydraulic applications.

| Feature | 4wmm Rexroth | Competitor Valves |

|---|---|---|

| Material Quality | High-grade steel and alloys | Varies, often lower-grade materials |

| Control Precision | High precision | Moderate to high precision |

| Operational Efficiency | Optimized for energy savings | Standard efficiency |

| Service Life | Extended service life | Shorter service life |

| Warranty and Support | Comprehensive warranty with strong customer support | Limited warranty, variable support |

The reliability of the 4wmm Rexroth is underscored by its widespread adoption across various sectors that require uncompromising performance and durability. According to a recent industry report by Global Industry Analysts, the demand for high-precision hydraulic components is on the rise, highlighting the importance of reliable products like those from Bosch Rexroth.

Market trends indicate a growing preference for advanced hydraulic systems that offer both efficiency and adaptability. As industries look to minimize costs and maximize output, the adoption of high-quality components like the 4wmm Rexroth valve corresponds with a broader shift toward automation and smart manufacturing. Companies across sectors are investing heavily in hydraulic solutions that promise to deliver better performance and lower operational costs, which directly fuels demand for the 4wmm Rexroth valve.

Customer testimonials and user feedback reinforce the valve's reputation for reliability. Manufacturers using the 4wmm Rexroth in their operations have reported significant improvements in operational efficiency and reduced maintenance costs. This consistent performance under real-world conditions adds to the increasing reliance on Bosch Rexroth products within key industries.

The market for hydraulic valves, including the 4wmm Rexroth valve, is also characterized by rapid technological advancements. As new features are continually integrated into hydraulic systems — such as IoT capabilities for real-time monitoring and data analytics — Bosch Rexroth ensures that they are at the forefront, adapting their products to meet the evolving needs of their customers.

To ensure the continued efficiency and longevity of the 4wmm Rexroth valve, proper maintenance practices are essential. Regular maintenance not only helps prevent costly breakdowns but also enhances the overall performance of hydraulic systems. Below are key maintenance practices that should be adhered to:

By following these maintenance practices, industries can maximize the lifespan and efficacy of the 4wmm Rexroth valve, ensuring that their hydraulic systems remain operational and efficient.

The 4wmm Rexroth valve is a benchmark in hydraulic systems, epitomizing the blend of engineering precision and industrial strength. Its extensive use across diverse fields attests to its efficiency, durability, and superior control capabilities. By ensuring that hydraulic systems function seamlessly, the 4wmm Rexroth continues to cement its place in the vanguard of industrial innovation and application.

As industries continue to innovate and seek greater efficiencies, the relevance of solutions like the 4wmm Rexroth valve cannot be overstated. With its capacity to adapt to modern requirements of automation and real-time data usage, it stands poised to support the next generation of hydraulic applications. Investment in such technology not only enhances productivity but also ensures that businesses remain competitive in a rapidly changing landscape.

In summary, the 4wmm Rexroth valve is not just an integral component of hydraulic systems; it is a crucial player in the broader narrative of industrial advancement, embodying the qualities of performance, durability, and adaptability. As we look towards the future, the evolution of the 4wmm Rexroth valve will continue to address the ever-growing demands of industries worldwide, proving that in the realm of hydraulic systems, quality and innovation go hand in hand.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!