Rexroth Tc08 is a sophisticated hydraulic component renowned for its reliability and efficiency in industrial applications. This guide explores its features, uses, and advantages in various settings, highlighting its role in enhancing operational performance. We'll delve into a detailed examination of its functionalities, providing insightful perspectives from industry experts on its impact and value.

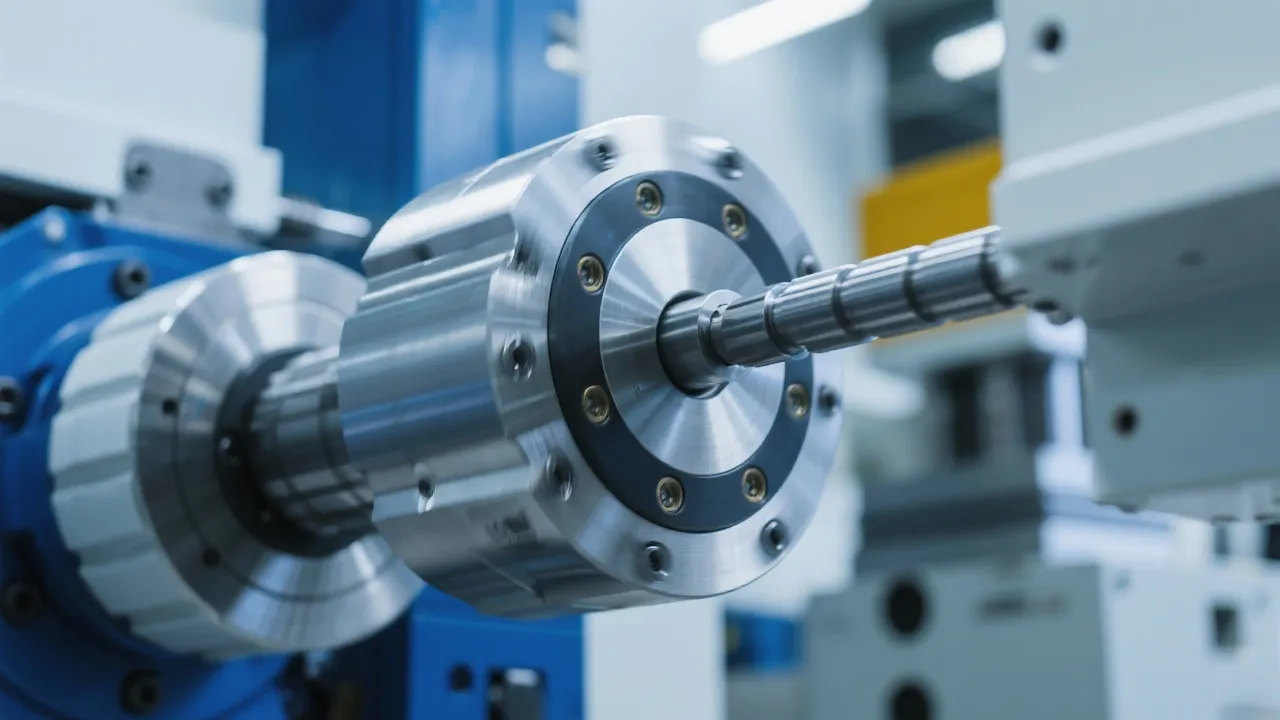

The Rexroth Tc08 is an integral component in the realm of hydraulic technology, offering extraordinary precision and reliability. As with many Rexroth solutions, the Tc08 model is revered for its engineering excellence and adaptability in various industrial applications. Renowned for its efficiency, the Rexroth Tc08 plays a crucial role in enhancing industrial machinery performance and productivity across multiple sectors. It is essential to delve into the mechanics and features of this device to fully appreciate its impact on industry standards.

At the heart of the Rexroth Tc08 are several innovative technologies that set it apart from other components. These features include advanced control mechanisms allowing for precise calibration and seamless integration with other machinery systems. The user-friendly interface provides operators with real-time data and operational metrics, which aid in decision-making and troubleshooting. The benefits of using the Rexroth Tc08 range from increased operational efficiency to reduced downtime due to its durable design and high-quality materials. Elevated performance leads to overall cost savings and enhances production capabilities, making the Tc08 an indispensable asset for modern industry.

Moreover, the Rexroth Tc08 is designed with energy efficiency in mind. Its lightweight materials and advanced hydraulic circuit design minimize energy consumption without compromising performance. This aspect not only contributes to more sustainable operations but also reflects an industry trend towards environmentally conscious manufacturing practices. Additionally, the Tc08 is equipped with advanced diagnostic features that enable predictive maintenance protocols, allowing companies to anticipate failures before they occur, thus reducing unplanned downtime and operational disruptions.

The versatility of the Rexroth Tc08 extends its use across various industries. In manufacturing plants, it is employed to streamline production lines, ensuring consistent output quality while maintaining high operational speeds. This adaptability is crucial in environments where precision and timing are critical to the manufacturing process. For instance, in the electronics sector, where components are often assembled at high speeds with utmost precision, the Tc08 provides the necessary hydraulic control for pick-and-place machines and assembly robots.

In construction, its robust design supports heavy-duty machinery operations, promoting safety and reliability on site. Excavators and cranes, often subjected to enormous stress and demanding operating conditions, benefit substantially from the power and stability offered by the Tc08. Its ability to maintain consistent hydraulic pressure ensures that such machinery operates smoothly and efficiently, reducing the risk of accidents and improving project timelines.

The automotive industry also benefits from the Tc08's precision, significantly enhancing assembly line processes. From the stamping of metal sheets to the assembly of intricate components, the hydraulic control offered by the Rexroth Tc08 facilitates high-speed manufacturing with minimal errors. Moreover, its adaptability allows for integration into various stages of vehicle production, from engine assembly to chassis construction.

Beyond these sectors, the food and beverage industry has increasingly turned to the Rexroth Tc08 for its operational reliability. In this environment, where hygiene and consistency are paramount, the Tc08 supports valuable automated systems that handle and package products without compromising safety or quality. The ongoing demand for automation in food processing facilities aligns perfectly with the capabilities of the Rexroth Tc08, given its robust nature and ability to integrate with existing systems.

| Feature | Rexroth Tc08 | Comparable Model |

|---|---|---|

| Operating Pressure | Up to 250 bar | Up to 200 bar |

| Material Durability | High-grade steel composite | Standard steel |

| Control Precision | ±0.01 mm tolerance | ±0.05 mm tolerance |

| Integration Capability | Seamless with current systems | Limited compatibility |

As demonstrated in the table above, the Rexroth Tc08 offers superior performance across several key metrics, underscoring its position as a leader in hydraulic components. The operating pressure and material durability directly correlate to the longevity and reliability expected in demanding industrial environments. Additionally, the exceptional precision control makes it an attractive choice for applications where minute adjustments can lead to significant project success.

Installing and maintaining the Rexroth Tc08 requires a systematic approach to ensure optimal performance. Steps include regular calibration checks, consistent lubrication schedules, and professional installation by qualified personnel. These practices not only maximize the component's lifespan but also promote operational safety and dependability. Proper training for personnel who interact with the Tc08 is crucial, as it allows for quicker troubleshooting and more efficient use of the technology.

Another critical aspect of incorporating the Rexroth Tc08 into existing systems is ensuring compatibility with other hydraulic components. This includes evaluating existing pumps, valves, and cylinders to determine if upgrades are necessary. During this integration process, it is recommended to consult Rexroth’s technical support teams or certified partners to guarantee a seamless transition. Furthermore, leveraging software tools for system monitoring can enhance the efficiency of the Rexroth Tc08 during operations by allowing real-time adjustments and feedback within the hydraulic circuitry.

The Rexroth Tc08 is designed for longevity, with an expected operational lifespan exceeding 15 years under standard usage conditions. It is important to note, however, that this lifespan can be significantly influenced by the frequency of use, maintenance practices, and the operational environment. For instance, harsh conditions such as extreme temperatures or exposure to corrosive materials can affect durability. Regular assessment of wear and tear, along with timely component replacement, further contributes to extending the lifespan of the Tc08 in any application.

Yes, one of its defining characteristics is its compatibility with a wide range of industrial setups, including older machinery models. Rexroth's engineering teams have designed the Tc08 to integrate with existing hydraulic systems without requiring extensive modifications. This retrofitting capability provides manufacturers with the flexibility to upgrade without the need for complete machinery overhauls, ensuring cost-effective enhancements to operational capabilities.

Regular inspections, lubrication, and calibration are advised to maintain its high-performance standards and extend its service life. Specifically, operators should implement a schedule for checking seals and gaskets for wear, inspecting hydraulic fluids for contamination, and monitoring performance parameters using diagnostic tools. Depending on operational intensity, more frequent checks may be necessary. Additionally, training operational staff on maintenance protocols can help minimize errors and optimize operational efficiency.

Real-world applications of the Rexroth Tc08 can provide valuable insights into its effectiveness across various industries. One notable case involves a leading automotive manufacturer that sought to increase assembly line productivity. They integrated the Rexroth Tc08 into their existing hydraulic systems, focusing on critical operations such as welding and adhesive application. The result was a 30% increase in throughput, accompanied by a significant reduction in defects due to the enhanced precision of the hydraulic controls.

In another scenario, a construction firm faced challenges with the reliability of their hydraulic excavators on rough terrain. By retrofitting their existing machines with the Rexroth Tc08, they observed improvements in machine stability and control, leading to safer and more efficient worksites. The excavators were able to perform complex excavations more effectively, cutting down project times and reducing operational costs, which was instrumental in securing future contracts.

Furthermore, a food processing company incorporated the Rexroth Tc08 into their packaging operations, aiming to reduce waste and enhance product quality. By ensuring precise control of packaging machinery, they minimized material waste by nearly 15% and improved the overall operational speed, resulting in cost savings. The enhancement in packaging quality also led to fewer customer complaints regarding product integrity, highlighting the positive downstream effects of incorporating this technology into their processes.

As industries continue to evolve towards automation and digitalization, the future of hydraulic technologies, including models like the Rexroth Tc08, looks to incorporate smart technologies. Innovations such as IoT (Internet of Things) integration enable real-time monitoring and data analytics, allowing for predictive maintenance and further reducing downtime. For instance, sensors equipped with analytics capabilities could provide alerts for impending failures, allowing for proactive interventions before issues escalate.

Additionally, advancements in material science may lead to even more durable and lightweight components, enhancing performance while reducing energy consumption. The industry may move towards more environmentally friendly hydraulic fluids and biodegradable materials, aligning with global sustainability goals. Manufacturers like Rexroth are likely to expand their product offerings to include “green” technology while maintaining high efficiency standards.

Another critical trend is the push for standardization and modular designs, which provides greater flexibility and facilitates upgrades without extensive need for infrastructure changes. As systems become more interconnected, the focus will shift toward creating hydraulic solutions that can integrate with various manufacturing processes seamlessly. This evolution will enhance not only the efficiency of hydraulic systems but also their flexibility to adapt to diverse manufacturing requirements.

The Rexroth Tc08 stands out as a premier choice for industries seeking to enhance their hydraulic systems' efficiency and reliability. Its innovative design and robust performance make it a valuable asset in streamlining operations and minimizing downtime. By incorporating expert insights and real-world applications, this analysis provides a comprehensive view of how the Rexroth Tc08 can elevate industrial operations, propelling them into a future defined by efficiency and sustainability. As businesses continue to seek solutions that promote productivity while reducing their environmental impact, hydraulic technologies like the Rexroth Tc08 will undoubtedly play an essential role in shaping the next generation of industrial machinery.

With the relentless pace of industry advancement and technological integration, staying informed about emerging trends will be vital for those keen on leveraging hydraulic technology to its fullest potential. The ongoing development of the Rexroth Tc08, alongside anticipated innovations, positions it as a pioneering solution amidst an evolving industrial landscape.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!