The Rexroth Tc08 is a prominent product in industrial automation, part of Bosch Rexroth's innovative solutions to enhance process efficiency and reliability. This article delves into its features, applications, and the transformative impact it has had in various sectors worldwide. As automation continues to evolve, products like the Rexroth Tc08 are pioneering the integration of technology into everyday industrial operations.

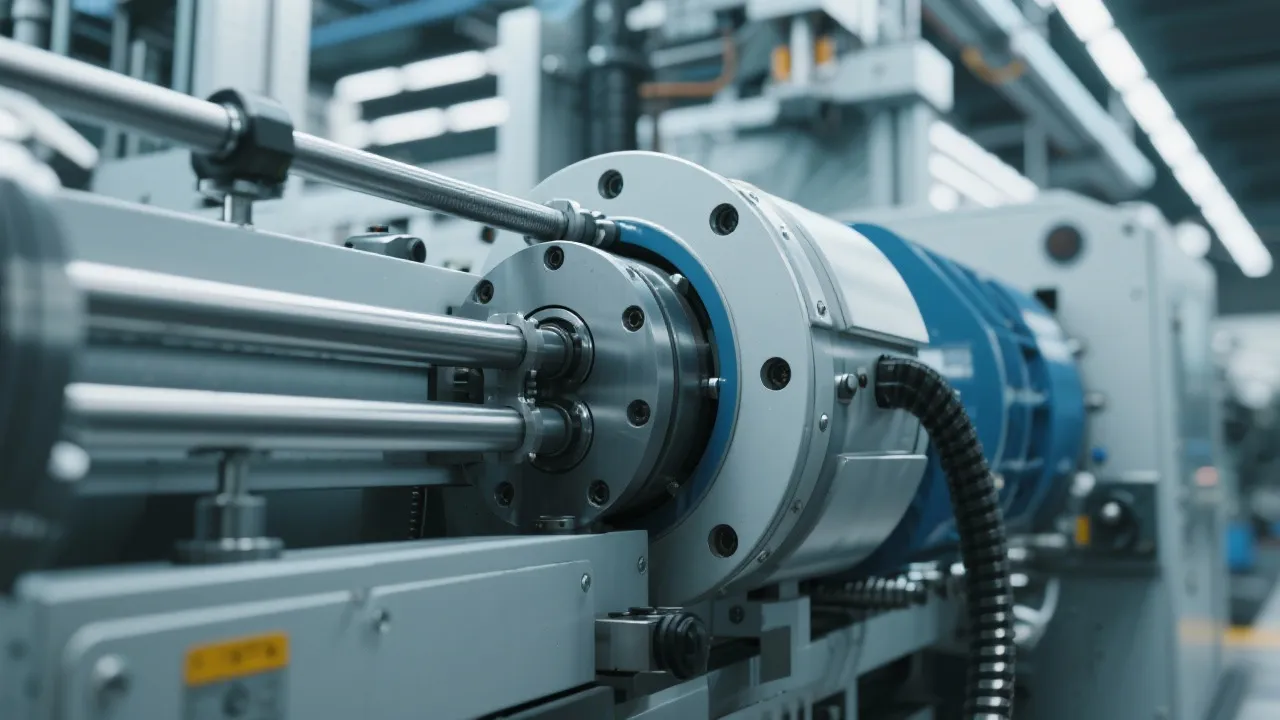

The Rexroth Tc08 stands as a testament to Bosch Rexroth's commitment to innovation in industrial automation. This piece of machinery represents a convergence of reliability, efficiency, and state-of-the-art technology, designed to meet the dynamic needs of modern industrial processes. As industries increasingly pivot towards automated solutions to enhance productivity and safety, understanding the capabilities of such systems is critical.

The growth of automation across various sectors has fundamentally changed operational architectures. By incorporating advanced technologies, systems like Rexroth Tc08 pave the way for heightened productivity levels, reduced operational costs, and improved safety standards. Automation systems will be investigated thoroughly in this article, examining both theoretical underpinnings and practical implementations of the Rexroth Tc08 to highlight its transformative potential in lieu of prevailing industry demands.

The Rexroth Tc08 is renowned for its precision and adaptability across various industrial applications. It incorporates cutting-edge technology to facilitate seamless integration into existing systems while delivering superior performance. Key features include advanced digital control, robust hardware architecture, and a user-friendly interface that allows operators to easily monitor and manage operations. These attributes make it a preferred choice in sectors ranging from manufacturing to automotive and beyond.

Moreover, the system's unparalleled performance is further complemented by its durability and low maintenance requirements, which collectively offer significant cost reductions over time. The ability to operate in high-stress environments without frequent interventions makes the Rexroth Tc08 a practical investment for businesses looking to maintain smooth operations. Its high MTBF (Mean Time Between Failures) metric signifies enhanced reliability, providing peace of mind for facilities that prioritize continuous production.

Another crucial aspect of the Rexroth Tc08 is its advanced connectivity options. Offering various communication protocols, including EtherNet/IP, PROFINET, and fieldbus systems, the TC08 can easily integrate into modern automation ecosystems. This compatibility ensures the smooth exchange of data and enables real-time monitoring, which is vital for maintaining optimal performance standards. Integration with IoT (Internet of Things) devices allows for improved data analytics and operational insights, solidifying the Tc08's status as an indispensable tool for industrial automation.

Moreover, its energy-efficient design aligns with global sustainability efforts, helping industries minimize their environmental impact without compromising on productivity. Innovative energy recovery methods further enhance its efficiency, allowing excess energy to be harnessed and reused in other processes, ultimately leading to lower energy costs and reduced carbon footprints. This characteristic appeals to an increasingly environmentally-conscious market and demonstrates Bosch Rexroth's forward-thinking approach to product development and sustainability.

The versatility of the Rexroth Tc08 enables its application across a multitude of sectors. In manufacturing, it plays a crucial role in automating assembly lines, thereby increasing throughput and reducing human error. This automation has been particularly impactful in the electronics and consumer goods industries, where precision and speed are paramount. From robotic arms assembling small components to automated guided vehicles (AGVs) moving products along assembly lines, the Tc08 facilitates a level of efficiency that significantly improves production timelines.

In the automotive industry, it assists in tasks that require high precision, such as the assembly of engine components, ensuring consistency and quality in production. The introduction of robotics driven by Rexroth Tc08 technology has enabled manufacturers to enhance quality control by utilizing machine vision systems that monitor and verify each assembly step in real-time. This automated quality assurance ensures any defects are identified early, reducing costly recalls and boosting customer satisfaction.

Beyond its technical capabilities, the impact of the Rexroth Tc08 can be seen in its ability to revolutionize workflow efficiency and safety. Automation systems like this greatly reduce the potential for workplace accidents by taking over hazardous tasks, allowing human workers to engage in more strategic roles. The pivot towards using robots for dangerous tasks, such as handling hazardous materials or operating in extreme conditions, highlights a significant shift in the occupational landscape, as workers can now focus on roles that require critical thinking, creativity, and decision-making.

Additionally, various logistics companies have incorporated Rexroth Tc08 into their operations, benefiting from increased inventory management capabilities. The system can track materials flow and optimize warehouse space, which provides significant cost efficiencies. In sectors such as pharmaceuticals and consumer electronics, where timely delivery and flawless execution are critical, the implementation of the Tc08 enables swift data-driven decisions, minimizing delays and enhancing overall operational agility.

According to industry experts, the adoption of systems like the Rexroth Tc08 is pivotal in transitioning towards Industry 4.0. The system's integration capability with IoT devices allows for real-time data analysis, leading to more informed decision-making processes. Industry 4.0 represents a significant shift in production and supply chain management, where connected devices and advanced analytics become the cornerstone of efficiency and performance improvements. As businesses strive to remain competitive on a global scale, leveraging such advanced technology is not just advantageous, but essential.

Furthermore, an analysis conducted by the International Society of Automation in 2023 showed a direct correlation between automation investments and a significant improvement in operational efficiency. Companies that adopted advanced systems like Rexroth Tc08 reported up to 30% reductions in operational downtimes and a 20% increase in production output within the first year of implementation. These statistics reveal the tangible benefits derived from investing in technology, supporting the case for more widespread adoption across various industries.

Beyond the quantifiable metrics, qualitative feedback from industry leaders emphasizes the transformative impact of automation on workforce engagement and satisfaction. Workers accustomed to repetitive tasks report higher job satisfaction when they transition to supervisory and creative roles facilitated by systems such as the Rexroth Tc08. This aspect speaks to the broader implications of automation—where not only processes are enhanced, but the workforce itself is empowered, thereby leading to a more fulfilling work environment.

Successfully integrating Rexroth Tc08 into an operational workflow necessitates a well-planned implementation strategy. Here, we'll outline best practices to ensure the desired outcomes are achieved, maximizing return on investment and minimizing disruptions during the transition.

Before diving into implementation, it is crucial to assess the specific needs and operational gaps within the existing system. Engaging with stakeholders across all levels—and understanding their pain points—can provide valuable insights into where automation can deliver the most significant benefit. This step serves as the foundation for justifying the investment and aligning automation goals with broader business objectives.

Introducing new systems can be daunting; therefore, piloting the Rexroth Tc08 on a smaller scale can mitigate risks associated with full-scale rollouts. Select a specific area of the operation where automation could yield immediate benefits and monitor its performance closely. Insights gained from pilot testing can guide adjustments and refinements before full implementation, ensuring a smoother transition.

The success of any automation initiative significantly hinges on the workforce’s ability to adapt to new technologies. Invest in comprehensive training programs that not only cover technical parameters of operating the Rexroth Tc08 but also foster advanced analytics capabilities. Empowering employees through reskilling aligns their contributions with the organization’s evolving technological landscape, enhancing job satisfaction and productivity.

Once the Rexroth Tc08 is in operation, adopting a culture of ongoing assessment is essential. Utilize the analytics features of the system to continuously monitor performance metrics, identify bottlenecks, and gather data that inform future optimizations. Empower teams to make data-driven decisions and iterate processes based on real-world insights to continually refine performance.

To fully harness the capabilities of the Rexroth Tc08 and similar technologies, companies must cultivate a culture of innovation. This involves encouraging experimentation and risk-taking among staff, allowing new ideas to emerge without the fear of failure. Engaging employees in brainstorming sessions can lead to novel applications of existing technology and spur creative thinking that contributes to overall operational advancement.

| Question | Answer |

|---|---|

| What industries benefit most from Rexroth Tc08? | Manufacturing, automotive, aerospace, and logistics sectors benefit greatly due to the system's versatility and efficiency. |

| Is the Rexroth Tc08 energy-efficient? | Yes, it features an energy-efficient design that helps reduce operational costs while supporting environmental sustainability efforts. |

| Can it be integrated with existing systems? | Absolutely, the Tc08 is designed to seamlessly integrate with a wide range of existing industrial systems, enhancing their capabilities. |

| How does the Rexroth Tc08 enhance safety in the workplace? | By automating hazardous tasks, the system minimizes the risk of workplace accidents, allowing human workers to focus on safer, strategic roles. |

| What kind of data insights does the Rexroth Tc08 provide? | The Tc08 allows for real-time monitoring and data analysis, enabling operators to optimize processes, enhance quality control, and streamline operations. |

The Rexroth Tc08 is more than just an automation system; it's an integral component of modern industrial strategy. As industries globally steer towards greater automation, understanding and leveraging such advanced systems become indispensable. Innovations like these not only enhance productivity and safety but also ensure industries can meet future challenges with adaptability and foresight. As Rexroth Tc08 continues to shape industrial automation, it sets a benchmark for efficiency and technological advancement. The continuous development of technologies surrounding the Tc08 signifies an evolving narrative in industrial practices, demanding that organizations stay ahead of the curve to thrive in an ever-changing landscape.

Looking ahead, the trajectory of automation technology will likely include advancements that incorporate artificial intelligence (AI) and machine learning, honing further the capabilities of systems such as the Rexroth Tc08. The future will not just be about implementing automation but rather about how smart systems learn and adapt to improve processes in real-time. This integration could lead to even more significant strides in operational efficiency, productivity, and workforce development, underlining the importance of keeping pace with technological evolution.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!