This guide delves into the Rexroth Tc08, a crucial component in industrial machinery, known for its reliability and efficiency. Rexroth, a prominent name in engineering solutions, has developed the Tc08 to enhance operational performance across various industries. Understanding its mechanics and applications is essential for professionals seeking to optimize industrial processes.

In the realm of industrial machinery, efficiency and reliability are paramount. The Rexroth Tc08 is a pivotal component that exemplifies these qualities, making it an indispensable asset in numerous manufacturing settings. Known for its robust design and operational effectiveness, the Tc08 plays a critical role in ensuring seamless industrial processes. With the rise of automation and increased competition, maintaining high operational standards has never been more crucial. The Rexroth Tc08 stands out not only for its functionality but also for its adaptability to various technological advancements within the industry.

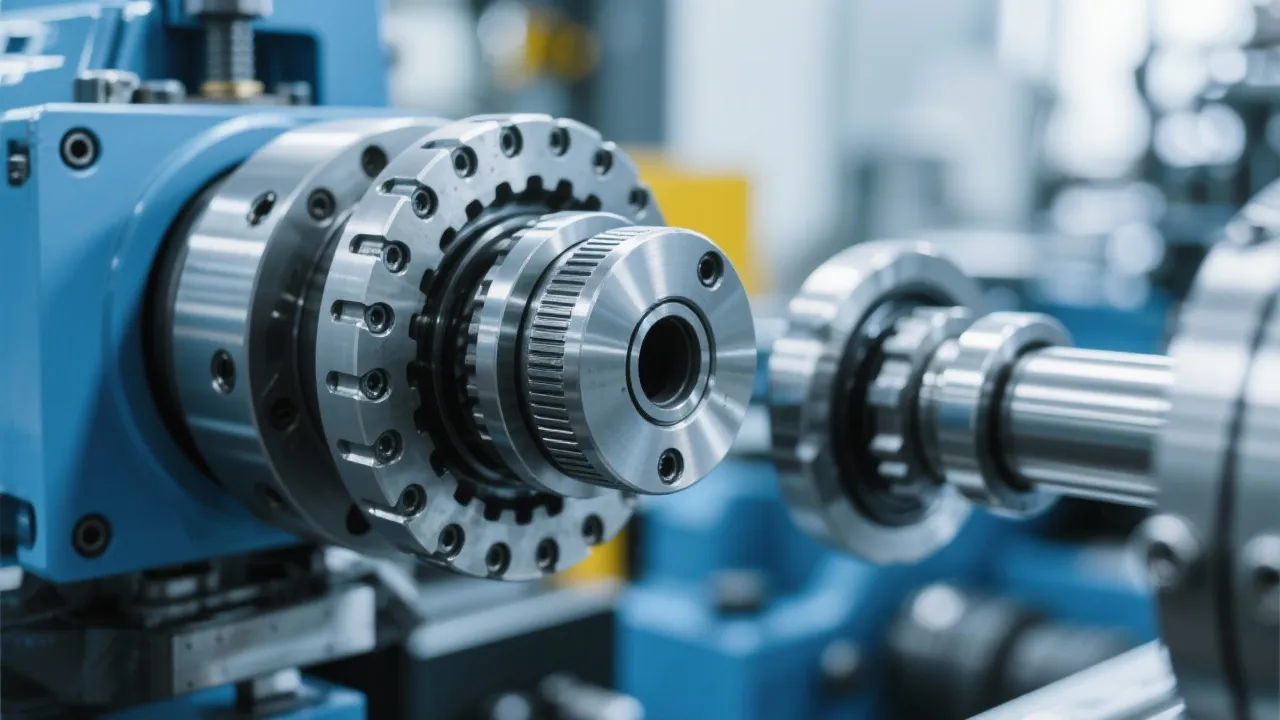

The Rexroth Tc08 is engineered with precision, embodying advanced technological innovations that cater to the demands of modern industry. Its design emphasizes durability and performance, allowing it to withstand the rigors of industrial operations. The meticulous engineering behind the Tc08 enables it to function efficiently, minimizing downtime and maximizing productivity. Key features include robust materials designed to resist wear and tear, as well as a compact configuration that reduces the spatial footprint of the machinery. The lightweight yet sturdy structure facilitates easy integration into existing equipment without major modifications.

Additionally, the Tc08 often incorporates smart technology features, including modular designs that facilitate upgrades and repairs. This intrinsic adaptability is particularly advantageous in industries vying for continuous improvement without incurring significant overhaul costs. As industries progress towards the Internet of Things (IoT) and Industry 4.0, the Tc08's design positions it as a forward-thinking choice for companies intent on keeping pace with technological developments.

This component is versatile, serving various sectors by enhancing their mechanical systems. From automotive to heavy machinery, the Tc08 is integral to maintaining smooth and efficient operations. Its flexibility allows it to adapt to different industrial requirements, making it a preferred choice for many engineering solutions. For example, in the automotive industry, the Tc08 is often used in assembly lines where precision and speed are critical. Its ability to work in tandem with various automation systems means companies can achieve higher output without compromising quality.

Moreover, the application of the Tc08 extends to sectors such as aerospace, where reliability and precision are non-negotiable. Here, it manages parts that undergo severe stress during flight, proving its resilience under extreme conditions. In heavy industries, including construction and mining, the durability of the Rexroth Tc08 ensures machinery operates effectively in harsh environments, which speaks to its broad applicability. The fact that it can seamlessly integrate with hydraulic systems only adds to its utility, allowing companies to implement comprehensive solutions across their operations.

Experts in the field recognize the Rexroth Tc08 for its contribution to improving industrial output. Its integration into machinery leads to enhanced operational capabilities, reducing inefficiencies and promoting sustainable practices. Industry leaders continuously highlight the importance of such components in driving innovation and growth. The rising trend towards sustainable manufacturing sees the Tc08 playing a significant role, as it helps reduce energy consumption and waste generation—two critical areas where modern factories are striving for improvement.

Furthermore, the insights from industry professionals emphasize not only the technical specifications of the Tc08 but also the profound impact it has on operational culture. Companies that adopt such advanced solutions foster a mindset geared towards innovation, encouraging teams to seek further enhancements and cutting-edge technologies. With a commitment to continuous improvement, businesses leveraging the Tc08 are better positioned to respond to evolving market needs, align with regulatory standards, and enhance overall customer satisfaction through reliable product offerings.

| Component | Function | Features |

|---|---|---|

| Rexroth Tc08 | Enhances mechanical efficiency | Durable, reliable, versatile, incorporates smart technology |

| Siemens Electric Motor | Power generation | Energy-efficient, robust, widely-used in various applications |

| Parker Pump | Fluid transport | High performance, compact design, customizable |

| Bosch Sensor System | Data acquisition | Precision monitoring, real-time analytics, integrates easily |

For industries aiming to optimize their processes, integrating the Tc08 is a strategic decision. Proper installation and regular maintenance are crucial to fully harness its potential. Partnering with certified professionals ensures that the component is utilized effectively, leading to good operational benefits. A systematic approach to integration involves thorough planning—taking into account the existing equipment, assessing compatibility, and mapping out potential operational disruptions during installation.

During the integration phase, considerable emphasis should also be placed on training personnel who will manage the Tc08. Understanding its functionalities and operational parameters empowers the workforce to address potential issues proactively. Continuous training modules focused on best practices for maintenance and troubleshooting further enhance the reliability of this critical component. To optimize performance, manufacturers often deploy a combination of predictive and preventive maintenance strategies, utilizing data analytics to preemptively address components’ health. This foresight not only prolongs the lifespan of the Tc08 but also contributes to the overall efficiency of industrial operations.

Modern industrial components must keep pace with technological advancement, and the Rexroth Tc08 is no exception. With innovative features, the Tc08 incorporates elements tailored to enhance functionality and adaptability in dynamic work environments. These innovations include advanced diagnostic capabilities that allow users to monitor real-time performance data, predicting potential failures before they escalate. This leading-edge functionality not only aids in preventive maintenance but also supports quality management and regulatory compliance by ensuring equipment adherence to industry standards.

Furthermore, the incorporation of IoT capabilities positions the Rexroth Tc08 as an integral part of smart manufacturing. With connected systems, data can flow seamlessly between various components and central monitoring systems, enabling complete visibility of operations. Companies can better understand their processes, thus fostering informed decision-making. Moreover, this connectivity enables remote monitoring, allowing for prompt interventions when irregularities are detected, thereby reducing the likelihood of operational disruptions.

To better understand the real-world impact of the Rexroth Tc08, let’s explore several case studies showcasing its application and effectiveness in various settings. One relevant case is in an automotive assembly line where the Tc08 was integrated into robotic systems for component handling. By employing the Tc08, the assembly line achieved a 20% increase in production speed while maintaining quality standards. Such improvements were attributed to the Tc08’s ability to precisely control the motion and positioning of the robotic arms, thereby reducing waste and optimizing time on task.

In another example, a mining company faced significant challenges with machinery maintenance due to harsh operational conditions. By implementing the Rexroth Tc08 into their heavy equipment, which operates under tough environments, they observed a 30% reduction in downtime. The enhanced durability and reliability of the component allowed for longer operational intervals and less frequent maintenance, translating to significant cost savings and greater operational efficiency.

The future of the Rexroth Tc08 technology appears promising, especially in light of ongoing trends shaping the industrial landscape. As industries increasingly adapt to automation and digitalization, we can expect the Rexroth Tc08 to evolve to include even smarter features. Integration with machine learning algorithms could provide further predictive maintenance capabilities, tailoring service schedules based on actual usage patterns rather than set intervals.

Moreover, sustainability continues to rise as a core business principle. Future iterations of the Tc08 may prioritize eco-friendly materials and reduced energy consumption in their operation, supporting organizations in their green initiatives. Collaborations with software developers could also see enhancements in data analytics, enabling users to better leverage the information collected through their systems for enhanced decision-making and efficiency. More broadly, as we move towards fully automated factories, the Tc08 will potentially play a crucial role in harmonizing the interactions among various automated systems, thereby ensuring fluid operations across complex manufacturing networks.

In summary, the Rexroth Tc08 is a testament to engineering excellence, offering unparalleled efficiency and reliability in industrial machinery. Its widespread application across various sectors underscores its significance in advancing manufacturing capabilities. Understanding and utilizing the Tc08 can lead to transformative improvements in industrial operations, positively affecting productivity, sustainability, and workplace safety. As technology continues to evolve, the Rexroth Tc08 is expected to remain at the forefront, adapting to the changing needs of the industry and serving as a cornerstone of modern manufacturing solutions.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!