The Rexroth 7291 is a pivotal component in hydraulic systems, renowned for its dependability and engineering excellence. Leveraging cutting-edge technology, it supports a variety of industrial applications, ensuring efficiency and reliability. This guide explores its design, implementation, and the value it adds to manufacturing processes.

The Rexroth 7291 signifies a benchmark in hydraulic component technology, known for its advanced engineering and robust performance. As a crucial element in numerous industrial sectors, it contributes significantly to the efficiency and functionality of hydraulic systems. This article delves into the nuances of the Rexroth 7291, offering a comprehensive understanding for industry professionals and enthusiasts alike.

In the realm of industrial hydraulics, precision, and reliability are paramount. The Rexroth 7291 meets these requirements with its superior design and cutting-edge materials, ensuring optimal performance under challenging conditions. Its application across various industries underscores its versatility and the trust placed by engineers in its capabilities.

The efficiency and durability of the Rexroth 7291 reduce downtime and repair costs, making it a cost-effective choice for businesses aiming to enhance their operational productivity. By ensuring stable and continuous operations, it supports the sustainability of manufacturing workflows and boosts output quality.

Bosh Rexroth, a global leader in drive and control technology, has established the Rexroth 7291 as a pivotal part of its hydraulic components lineup. The product is not only an engineering marvel but also embodies the principles of sustainability and environmental responsibility that are becoming increasingly important in modern manufacturing. The incorporation of recyclable materials and energy-efficient processes in the production of the Rexroth 7291 further solidifies its standing as a responsible choice for industries looking to minimize their ecological footprint.

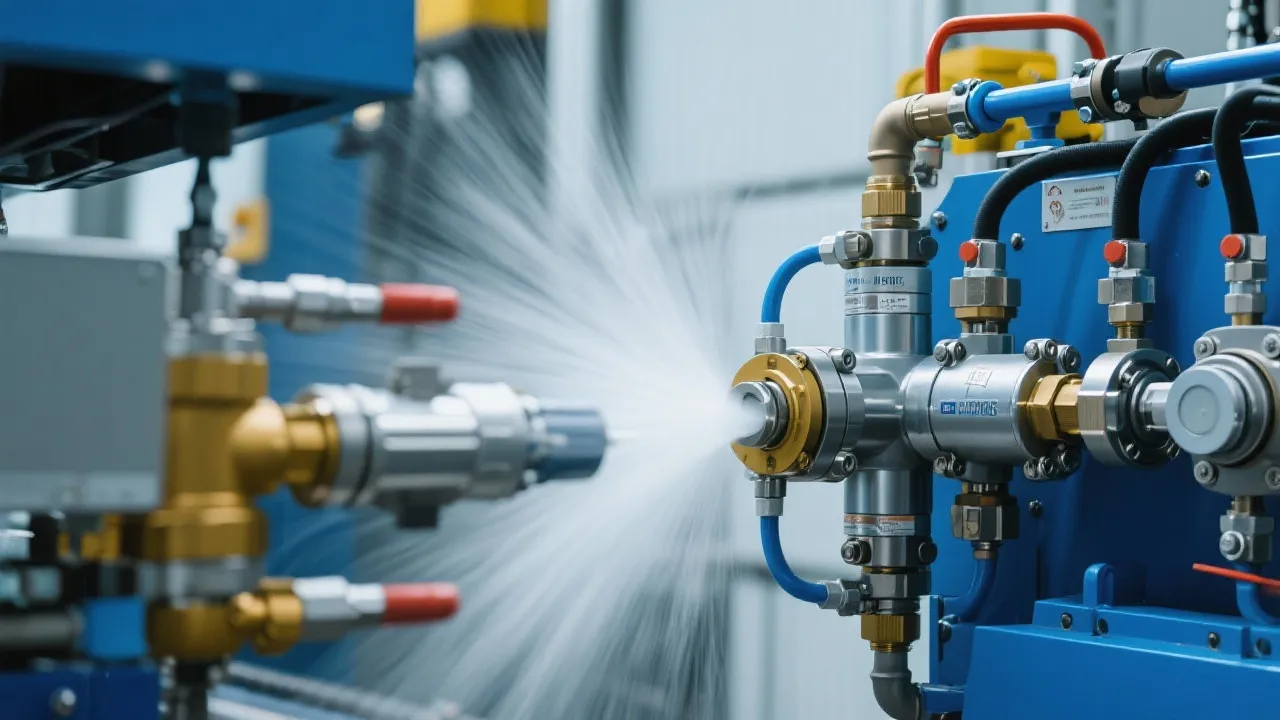

Engineered with precision, the Rexroth 7291 features a robust structure designed to withstand high-pressure environments. This makes it particularly suited for applications requiring dynamic movement and precise force control. Features such as corrosion resistance, heat tolerance, and energy efficiency are meticulously incorporated, contributing to its long-lasting performance.

The design process of the Rexroth 7291 involves extensive simulations and real-world testing, ensuring that each unit not only meets but exceeds industry standards. This rigorous approach instills confidence in operators and engineers who rely on its performance in critical applications, such as those found in robotics, construction machinery, and processing plants.

Moreover, the Rexroth 7291’s modular design facilitates seamless integration into existing systems, highlighting Bosch Rexroth's commitment to providing adaptable and versatile solutions. This results in reduced installation times and contributes to lower overall project costs. The integration capabilities extend beyond mere installation; the hydraulic component can interact with a range of sensors and control systems, allowing for enhanced automation and intelligent operation in advanced manufacturing environments.

The flexibility of the Rexroth 7291 enables its usage across various industries, including automotive, aerospace, and heavy machinery. Its reliable performance in these contexts ensures smooth operations, making it indispensable for companies aiming to maintain competitive advantages through enhanced productivity and innovation.

In environments such as manufacturing and assembly lines, where precision and repetitive tasks are critical, the Rexroth 7291 offers consistent and reliable power transmission, ensuring every movement is executed with exactness and control. For instance, automotive assembly lines depend on hydraulic systems powered by components like the Rexroth 7291 to achieve the necessary speed and precision for assembling different components into complex systems.

Additionally, the aerospace industry benefits from the Rexroth 7291's high-level performance, especially in hydraulic systems that are pivotal for the operation of aircraft systems such as landing gear and flap control. Its reliability under extreme conditions ensures that safety and performance standards are consistently met. Engineers in this field recognize that the reliability of hydraulic components can have far-reaching implications, making the choice of using Rexroth 7291 not just a functional decision but a safety imperative.

Construction machinery is another area where the Rexroth 7291 excels. In machines like excavators and bulldozers, which face rigorous operational demands, the component provides the hydraulic power necessary for efficient operation. Operators can trust in the durability of the Rexroth 7291, knowing that it can handle the tough working conditions typical of construction sites, thus allowing for increased uptime and productivity.

The Rexroth 7291 stands out as a testament to technological advancement in the hydraulic systems sector. It represents not just a component, but a cornerstone in achieving industrial excellence through innovative design and performance. Businesses around the globe continue to rely on it for maintaining the robustness and efficiency of their operations, signifying its status as a leader in hydraulic solutions.

As industries continue to evolve with the introduction of smart technologies, the role of advanced hydraulic components like the Rexroth 7291 is becoming even more pronounced. Future developments are likely to focus on further enhancing the efficiency and intelligence of hydraulic systems through the integration of IoT (Internet of Things) technologies. By embedding smart sensors within hydraulic components, real-time data can be gathered, enabling predictive maintenance and operational optimization.

The Rexroth 7291 is positioned to lead this transition, benefiting from Bosch Rexroth’s ongoing investments in research and development. This ensures that the component not only meets current industry demands but is also ready to embrace the future needs of automation, where the convergence of digital and physical systems requires hydraulic solutions to be smarter than ever before.

To illustrate the practical benefits of the Rexroth 7291, we can look at various case studies that demonstrate its effectiveness across different applications. In one notable example, a leading automotive manufacturer switched from traditional hydraulic actuators to the Rexroth 7291 in their assembly line. This transition not only improved their operational efficiency by 20% but also enhanced the accuracy of their component placements, significantly reducing the reject rate associated with assembly errors.

In another case, an aerospace components manufacturer adopted the Rexroth 7291 for use in its testing stations. These testing stations are critical for ensuring that all components meet stringent safety standards before they are used in actual aircraft. The implementation of Rexroth 7291 allowed the company to streamline its testing procedures, reduce cycle times, and ensure compliance with safety regulations without compromising quality.

Lastly, within the construction sector, an excavation company reported a 30% increase in productivity after installing the Rexroth 7291 in its hydraulic systems. The improvement was attributed to the component's reliability and efficiency, which allowed operators to complete tasks more quickly and with greater confidence, ultimately resulting in smoother project flows and higher customer satisfaction.

The hydraulic component market is competitive, with several leading manufacturers vying for leadership. However, the Rexroth 7291 distinguishes itself not only through its innovative engineering but also through Bosch Rexroth’s commitment to customer support and service. Companies choosing the Rexroth 7291 benefit from a comprehensive support system, including training programs tailored to help users maximize the component's potential in their operations.

In comparing the Rexroth 7291 with competitor products, it’s evident that while alternatives may offer similar specifications, the combination of Bosch Rexroth's global support network and cutting-edge technology provides a definite edge. Customers can rely on faster service, readily available spare parts, and expert consultations that enhance their operational decision-making.

With the increasing emphasis on sustainability, the hydraulic industry cannot remain static. The Rexroth 7291 is part of a broader trend towards environmentally friendly hydraulic solutions that minimize energy consumption and reduce emissions. Bosch Rexroth is actively working to develop hydraulic technologies that utilize bio-based fluids, reduce leakage, and optimize system integration to minimize resource waste.

The attention to environmental impact extends beyond product use—in manufacturing processes as well. The production of the Rexroth 7291 incorporates strategies that aim to reduce the waste generated during manufacturing, including recycling initiatives and energy-efficient practices to lower the overall carbon footprint. By choosing the Rexroth 7291, companies are not only investing in advanced technology but also contributing to a more sustainable future.

The Rexroth 7291 stands as a monument to innovation in hydraulic component design and functionality. Its meticulous engineering, responsiveness to industry demands, and commitment to sustainability make it an irreplaceable asset across numerous sectors. As trends toward automation and eco-conscious practices gain momentum, components like the Rexroth 7291 will play a pivotal role in shaping the future landscape of industrial hydraulics.

In summary, the Rexroth 7291's proven track record, coupled with the ongoing developments in its design and application, makes it a dynamic choice for forward-thinking companies focused on excellence in their hydraulic operations. With the future promising continued evolution, the Rexroth 7291 is perfectly positioned to remain at the forefront of hydraulic technology for years to come.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!