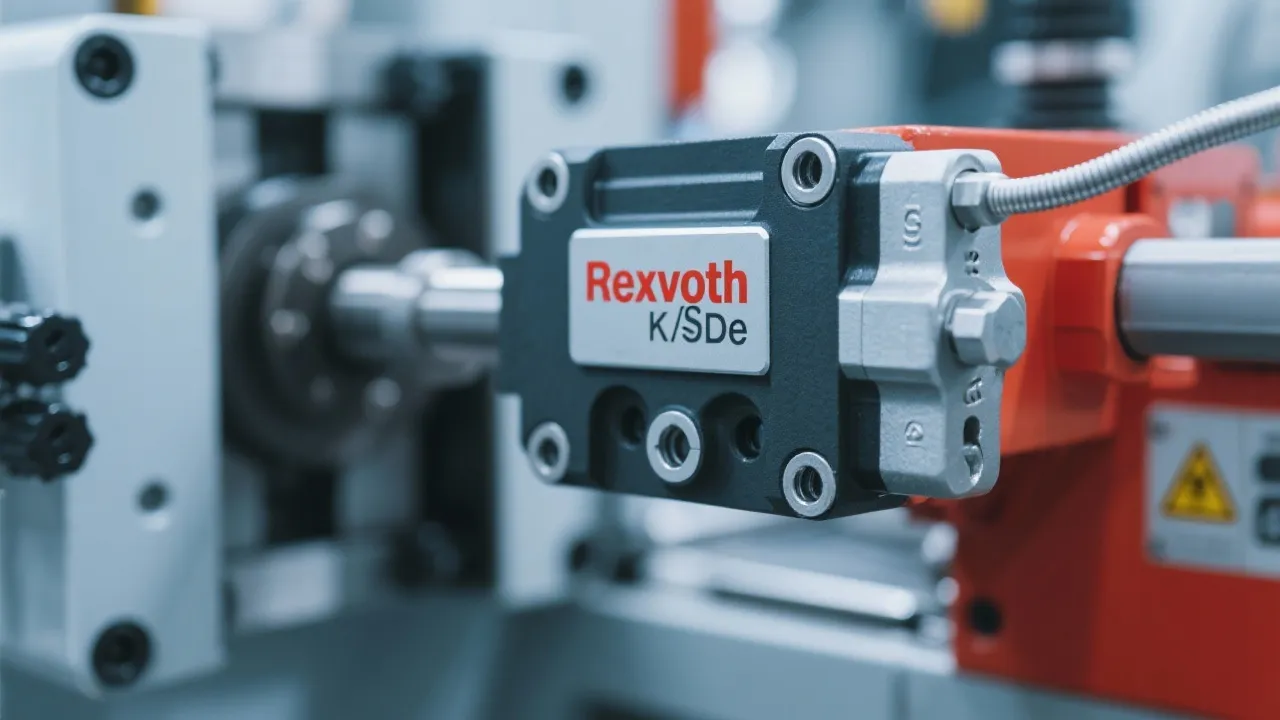

Rexroth Ksde plays a crucial role in modern industrial automation, offering precision and reliability in various applications. This article delves into the functionality, benefits, and advancements in Rexroth Ksde technology, guiding industry professionals through its myriad applications, and illustrating its impact on sectors from automotive manufacturing to energy solutions.

As industries around the globe strive for greater efficiency and precision, Bosch Rexroth's Ksde technology has emerged as a cornerstone in the realm of industrial automation. Known for its robust design and reliable performance, the Rexroth Ksde is essential in numerous sectors, significantly enhancing operational accuracy and productivity. From automotive production lines to renewable energy settings, its applications are diverse and invaluable. The technology integrates cutting-edge engineering principles to optimize manufacturing processes, compelling companies to rethink what is possible in industrial applications.

At its essence, the Rexroth Ksde technology symbolizes a modern approach to automation, incorporating smart systems that learn and adapt over time. This paradigm shift not only addresses the immediate functional needs of industries but also prepares them for the challenges of tomorrow’s manufacturing landscapes. In data-driven environments, connectivity plays a crucial role, and the Ksde technology is at the forefront of this transformation, fostering smarter factories driven by information and insights. With the increasing demand for customized products in shorter production cycles, the adaptability of the Ksde technology proves invaluable to manufacturers committed to maintaining a competitive edge.

One of the standout features of the Rexroth Ksde is its ability to deliver unparalleled precision in motion control. This capability is critical in manufacturing processes where even slight deviations can lead to significant waste or costly errors. By utilizing state-of-the-art sensors and control algorithms, the Rexroth Ksde ensures that equipment performs at its top, minimizing the risk of downtime and maximizing efficiency. This precision is not just about stopping errors but enhancing the overall speed at which processes can be completed, pushing the boundaries of what industries traditionally thought possible.

The automotive industry, for instance, benefits immensely from Ksde systems, which are integrated into assembly lines to enhance the precision of parts assembly. These systems enable the automation of tasks previously reliant on human intervention, significantly enhancing throughput while conserving resources. In addition, the renewable energy sector relies on these systems to optimize the alignment and functioning of components in wind turbines and solar panel installations, thus maximizing energy output and reducing operational costs. The impact stretches beyond financial margins; enhanced efficiency fosters broader sustainability goals by reducing the amount of raw materials needed and energy consumed in production.

Moreover, the data generated through the Ksde technology allows manufacturers to analyze trends and patterns that can inform better business decisions. Predictive analytics is another area where Ksde technology shines, as machine learning algorithms can forecast maintenance needs and potential failures, further preventing downtime and preserving resources. When combined with the Internet of Things (IoT) capabilities, the Ksde system can communicate with other machines on the factory floor, optimizing workflows across multiple operations.

Understanding the composition of the Rexroth Ksde reveals why it is so effective. At its core, the system comprises high-quality sensors, motors, and electronic controls that work in harmony to provide seamless operation. Each component is meticulously crafted to offer durability and performance consistency, even in high-demand environments. High-resolution encoders ensure that motion feedback is precise, allowing for tighter loops and finer control, which is critical for applications needing high degrees of accuracy.

The integration of intelligent control software adds another layer of functionality. Advanced control software enables real-time monitoring and adjustment, ensuring that industrial processes remain adaptive and responsive to changes. This adaptability is particularly advantageous in high-stakes environments where conditions can fluctuate rapidly, requiring immediate adjustments to maintain operational consistency. The user-friendly interface allows operators to set performance benchmarks, monitor outputs, and establish alerts for deviations from established parameters. Consequently, the overall operational envelope of industries can be efficiently expanded.

Furthermore, the modularity of the Ksde technology lends itself to scalability, allowing facilities to start with the most crucial components and expand their systems as needed. The interchangeability of components means that upgrading individual elements to meet evolving technological standards can be accomplished without needing a complete overhaul. As technology advances, the ability to integrate newer components while retaining existing ones enhances the longevity and investment value of the Ksde systems significantly.

Consider a manufacturing plant where precision is key for the automotive industry. The implementation of Rexroth Ksde systems in assembly lines has resulted in a marked improvement in production quality and speed. By automating critical phases of assembly, like welding and painting, the Ksde systems have minimized human error and improved overall efficiency. In one notable case, a major automotive manufacturer reported a 30% increase in productivity following the adaption of the Rexroth Ksde systems, a clear testament to the technology's effectiveness.

The automotive assembly line traditionally faced challenges such as variability in labor performance, discrepancies in assembly, and lengthy production cycles. With the introduction of a fully automated Rexroth Ksde system, these challenges were systematically addressed. For example, robotic arms equipped with Ksde-controlled motors accurately handled parts placement and adhesion, which not only reduced cycle times but also improved the structural integrity of the vehicles being produced. The implementation led to fewer recalls and defects, enhancing customer satisfaction and establishing a solid reputation in quality manufacturing.

Furthermore, time savings have led to increased throughput without the need for additional floor space, which is often at a premium in manufacturing settings. The flexibility of the Ksde systems allows for adjustments in production schedules without significant delays, thereby adapting to customer demands effectively. In a climate where customer preference can shift rapidly, this agility is crucial for sustaining competitive advantage.

When incorporating Rexroth Ksde systems into industrial applications, certain top practices optimize their impact. Ensuring proper calibration and regular maintenance checks are vital to sustaining performance levels. Establishing standardized operating procedures allows for consistent application of best practices across teams. Maintaining excellent documentation on settings, adjustments, and outputs not only aids in troubleshooting but facilitates training for new operators.

Additionally, integrating training programs for staff can maximize utilization, allowing operators to leverage the system's full capabilities effectively. Continuous education emphasizing technological advancements and operational improvements will foster a culture of innovation and encourage employees to advocate for further system enhancements based on firsthand experience. With a well-informed workforce, businesses are better positioned to capitalize on the full breadth of the Ksde technology's capabilities.

Moreover, engaging with experienced integration consultants during the implementation phase can smooth transitions and ensure the system aligns perfectly with operational needs. This partnership can also facilitate the identification of optimal configuration settings that may not be apparent at first glance. A feedback loop from operators to management about system performance and limitations can highlight areas for further training or system upgrades.

In today’s competitive industrial landscape, leveraging advanced technologies like the Rexroth Ksde system can be transformative. Its precision, reliability, and adaptability not only address the current demands of various industries but also pave the way for future innovations. By investing in such sophisticated systems, industries can ensure sustained growth, operational excellence, and competitive edge. The potential of Rexroth Ksde goes beyond immediate improvements; it sets the stage for a future where smart automation leads to unprecedented levels of efficiency and sustainability.

As industries continue to navigate the complexities of modern manufacturing, embracing technologies like Rexroth Ksde is paramount. This technology signifies not just an evolution in automation but a revolutionary step toward operational dynamism that can address the fast-paced and ever-changing demands of global markets. Companies that harness the power of Rexroth Ksde technology today will be the leaders of tomorrow, setting standards in productivity while championing sustainable practices that safeguard our resources for future generations. The road ahead is bright, and the implications of adopting such advanced technology are profound, demonstrating that with the right tools, there is no limit to what industries can achieve.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!