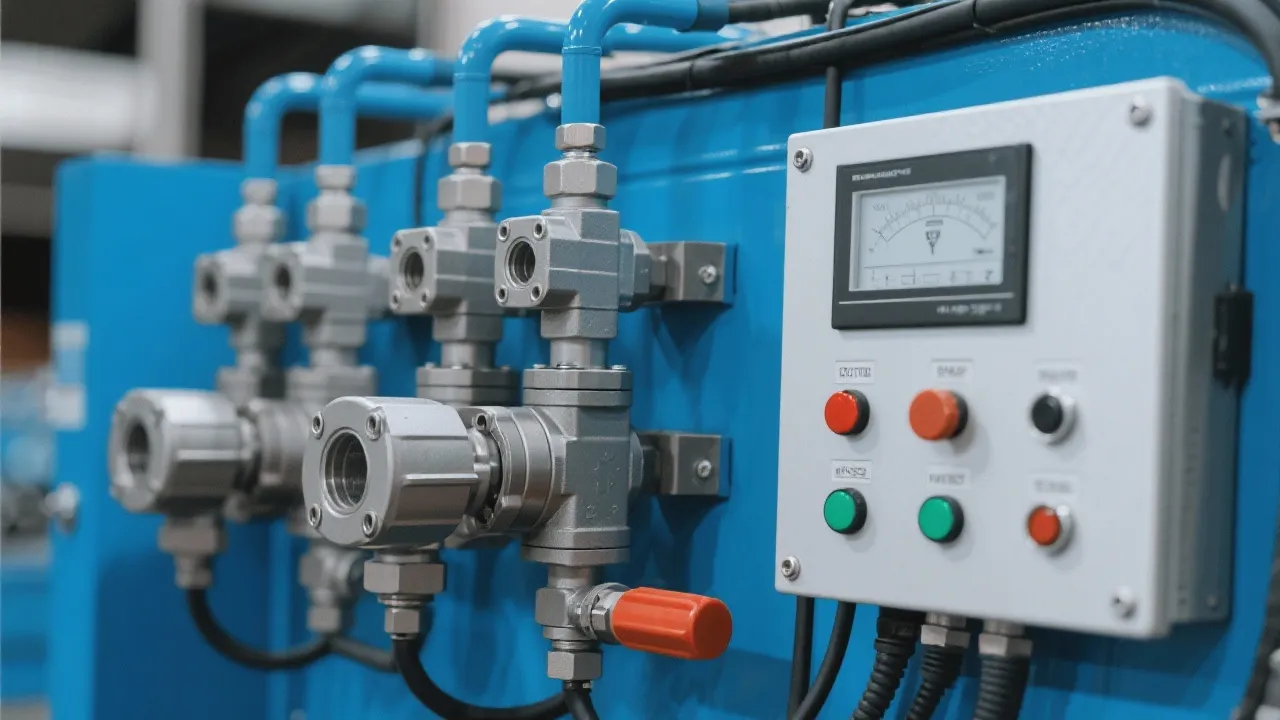

This article provides an in-depth exploration of the Rexroth Dz6dp2, a premium hydraulic directional valve renowned in industrial automation. Recognized for its reliability and precision, the Dz6dp2 valve plays a critical role in controlling the flow of hydraulic fluids, thereby optimizing the performance and efficiency of various machinery and systems in advanced industrial applications.

The Rexroth Dz6dp2 stands as a reputable component in the intricate world of hydraulic systems, primarily known for its consistency and performance. As industries advance toward more automated and efficient operations, the role of precision components like the Rexroth Dz6dp2 becomes increasingly significant. This hydraulic valve is engineered to control the direction of fluid flow within complex machinery, thereby governing the operations and ensuring optimal performance. The valve’s construction emphasizes reliability and efficiency, making it a vital element for a multitude of applications ranging from automotive machinery to large-scale industrial equipment.

At the heart of the Rexroth Dz6dp2 valve is its robust design, which supports both durability and high performance under various environmental conditions. Made with premium materials, it offers resistance to wear and tear, extending the life and efficiency of industrial hydraulic systems. The valve's precision-engineered components facilitate accurate control, crucial for processes that rely on exact specifications. Beyond its physical attributes, the Dz6dp2 is also adaptable, available in variations that cater to different operational needs, further enhancing its practical application across multiple sectors.

The versatility of the Rexroth Dz6dp2 valve is evident in its widespread application across various industries. From manufacturing and automotive to aerospace and construction, the valve is integral in areas requiring precise flow control. Its adaptability allows it to be customized for specific requirements, enhancing operational efficiency in diverse environments. The valve is widely utilized in mobile hydraulics, where reliable performance is essential for equipment such as cranes, excavators, and agricultural machinery. Additionally, its application extends to stationary hydraulics in industries like our commercial vehicles, metal processing, and energy production.

| Valve Model | Flow Capacity | Operating Pressure | Material | Special Features |

|---|---|---|---|---|

| Rexroth Dz6dp2 | 60 l/min | 350 bar | Alloy Steel | Corrosion resistant, High Precision |

| Model XYZ | 50 l/min | 300 bar | Stainless Steel | Integrated Sensors |

| Model ABC | 70 l/min | 400 bar | Aluminum Alloy | Lightweight, High Durability |

According to industrial automation experts, the integration of advanced hydraulic components like the Rexroth Dz6dp2 can significantly reduce downtime and increase machine life. This component, due to its precision control, aids in achieving seamless operation cycles, thus contributing to increased productivity and safety. Experts note that hydraulic systems often face challenges such as pressure fluctuations and fluid dynamics that require robust solutions. The Dz6dp2 effectively addresses these by maintaining stability and reliability, making it a preferred choice in high-stakes applications.

Proper installation and maintenance are critical to maximizing the lifespan and functionality of the Rexroth Dz6dp2 valve. It is recommended that installation be handled by certified professionals familiar with hydraulic systems to avoid any potential malfunctions. Additionally, regular maintenance checks are advisable to ensure the valve operates within its optimal range, preventing unforeseen disruptions in operations. Such maintenance typically includes monitoring fluid levels, checking for leaks, and inspecting seals and connectors for wear. Implementing a routine diagnostic schedule can further enhance the operational reliability of the hydraulic system.

When installing the Rexroth Dz6dp2, follow these crucial steps to ensure proper setup:

Engaging in best practices for maintenance can prevent issues that may lead to costly repairs. Here are some best practices to consider:

In summary, the Rexroth Dz6dp2 valve stands out as a pivotal component in hydraulic systems, embodying efficiency, reliability, and precision control. Its robust design and versatile applications across industries solidify its status as a preferred choice among industry professionals. Ensuring proper installation and observance of maintenance routines can enhance its performance and longevity. As technology continues to evolve, the demand for sophisticated components like the Rexroth Dz6dp2 will undoubtedly grow, propelling industries toward greater productivity and innovation.

The future of hydraulic systems looks promising, with advancements fostering more adaptive, efficient, and automated solutions. The Rexroth Dz6dp2 valve will continue to play an integral role in this evolution, reinforcing the importance of quality engineering and innovation in sustaining industrial progress. As industries move forward, embracing the essential capabilities offered by valves like the Dz6dp2 ensures a path towards operational excellence and long-term success in an increasingly competitive market.

For those interested in diving deeper into the world of hydraulic systems and valves, consider exploring the following resources:

By leveraging these resources, professionals can enhance their understanding of hydraulic systems, ensuring they stay at the forefront of industry standards and technological advancements.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!