This comprehensive article explores the functionality and applications of Rexroth Poppet Valves, core components in hydraulic systems. Poppet valves designed by Rexroth are crucial for controlling hydraulic and pneumatic fluid flow in various industrial applications. These valves are distinguished by their exceptional durability, precise control, and ability to handle high-pressure systems, making them integral to efficient industrial operations.

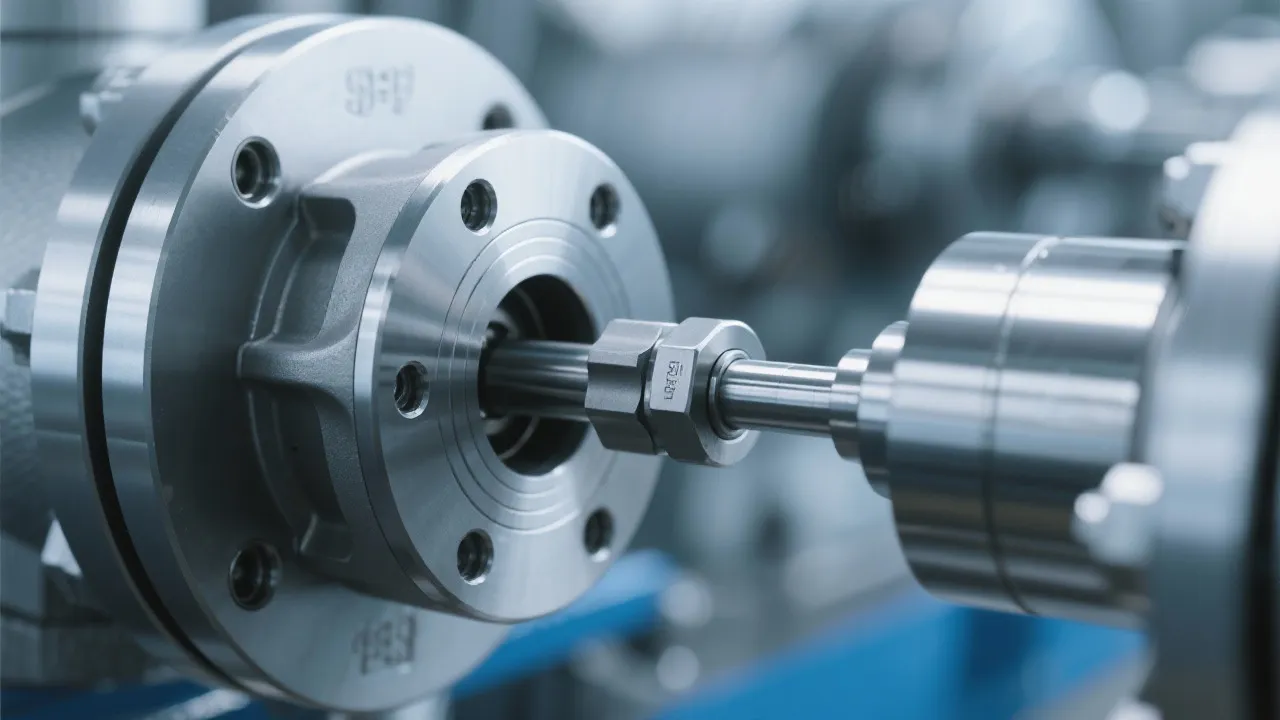

Rexroth Poppet Valves are integral components in hydraulic systems, utilized for their reliability, precision, and capability to handle high pressures. These valves, manufactured by Bosch Rexroth, are designed to control and direct fluid flow within hydraulic and pneumatic systems, thereby playing a crucial role in various industrial applications. The advanced engineering behind these valves ensures robust performance, making them essential for industries ranging from manufacturing to automotive and aerospace. As industries evolve and demand higher efficiency and precision, the importance of robust components like Rexroth Poppet Valves becomes even more apparent.

Rexroth Poppet Valves feature a simple yet highly effective mechanism that involves a poppet moving in response to pressure changes to allow or obstruct flow. This design ensures minimal leakage and offers precise control over fluid dynamics. Notably, these valves are appreciated for their durability and ability to function efficiently under high-pressure conditions. Additionally, they are manufactured using advanced materials and technologies, ensuring longevity and reduced maintenance needs. For example, the use of high-grade steel and composite materials enhances their functionality and resilience, providing significant advantages in various applications.

| Feature | Description |

|---|---|

| Durability | Constructed using high-quality materials for extended life under high-pressure operations. |

| Precision Control | Allows for meticulous management of fluid flow, essential for complex hydraulic systems. |

| Leak-Proof Design | Ensures efficient operation with minimal fluid loss, enhancing system reliability. |

| Versatility | Suitable for both hydraulic and pneumatic applications, adapting to various industrial needs. |

| Easy Integration | Designed for simple incorporation into existing systems, facilitating upgrades and modifications. |

The versatility of Rexroth Poppet Valves makes them suitable for a range of applications. In the automotive industry, they are used in braking systems and other critical hydraulic functions. Manufacturing sectors utilize these valves for machinery operations requiring precise flow control. Furthermore, the aerospace industry relies on these valves for systems where high reliability and pressure management are pivotal.

In the construction sector, these valves are essential for operating hydraulic excavators and cranes, enabling precise movements and control under load. Additionally, they are extensively used in agricultural machinery where the ability to manage flow rates can significantly enhance productivity and efficiency.

In the realm of energy, Rexroth Poppet Valves find application in wind turbines and other renewable energy systems, where fluid control is crucial for operation and safety protocols. Their ability to withstand extreme pressures and maintain functionality makes them ideal in such critical areas where failure is not an option.

When choosing hydraulic components, it's vital to understand the distinctions between different valve types. The table below highlights how Rexroth Poppet Valves stand against other valve types:

| Type | Rexroth Poppet Valve | Other Valves |

|---|---|---|

| Control Precision | High | Varies |

| Durability | Excellent | Good |

| Leakage Potential | Minimal | Moderate |

| Response Time | Fast | Slower |

| Operational Range | Broad | Narrower |

This comparative analysis underscores the advantages of Rexroth Poppet Valves, especially in applications requiring reliability, durability, and precision. Understanding these differences is essential for engineers and technicians tasked with selecting the appropriate components for their unique system requirements.

While Rexroth Poppet Valves are designed for durability, regular maintenance is essential to ensure peak performance. Routine inspections help identify signs of wear, potential leaks, and ensure that valves operate within specified parameters. Adequate lubrication and timely replacement of worn components can prevent operational failures and extend the lifespan of the valve system.

In practice, one might conduct regular visual inspections for any signs of leaking or corrosion and perform functional tests to ensure proper operation. Training operators and maintenance personnel on the specifics of the valves can provide insights into potential issues and help ensure that maintenance procedures are adhered to. Proper documentation of maintenance activities is critical in maintaining operational integrity and reliability.

Furthermore, utilizing advanced monitoring systems can enhance maintenance routines. Monitoring systems can provide real-time data on valve performance, allowing for predictive maintenance strategies rather than reactive approaches, which can save time and resources in the long run.

What makes Rexroth Poppet Valves superior to other hydraulic valves?

Rexroth Poppet Valves are renowned for their durability, precision control, and minimal leakage. The robust engineering design allows for reliable performance under high-pressure conditions, which is essential for many hydraulic systems. These factors make them superior in performance and reliability compared to many other hydraulic valves.

How often should these valves be serviced?

Regular inspections are recommended every six months, with a full maintenance check annually to ensure optimal performance and safety. However, the specific frequency might vary depending on operating conditions and the demands of the application in which they are employed.

Are these valves suitable for all industrial applications?

While Rexroth Poppet Valves can be used in a wide variety of industries, it's important to assess specific application requirements and pressure conditions to determine suitability. They excel in environments demanding high reliability and precision, but proper evaluation is key to ensuring they meet specific needs.

What is the pressure range for Rexroth Poppet Valves?

Rexroth Poppet Valves are designed to handle a wide range of pressures. Typically, they can operate effectively in systems requiring pressures up to 700 bar (approximately 10,000 psi), making them suitable for high-demand industrial applications. It’s always recommended to consult specific product data sheets for precise capabilities.

Can Rexroth Poppet Valves be used in both hydraulic and pneumatic systems?

Yes, one of the key advantages of Rexroth Poppet Valves is their versatility, as they can be utilized in both hydraulic and pneumatic applications. This flexibility allows manufacturers and engineers to standardize components across various systems, which can ease the design and maintenance processes.

Do these valves require special installation procedures?

While Rexroth Poppet Valves are designed for easy integration into existing systems, it is crucial to follow the manufacturer's guidelines during installation. Proper alignment, seal integrity, and torque settings are vital to ensure optimal function and prevent future issues.

In conclusion, Rexroth Poppet Valves represent a pinnacle of engineering in fluid control systems. Their robust design and precision functionality make them indispensable in high-demand industrial applications. Ensuring proper maintenance and understanding their comparative advantages can significantly enhance operational efficiency and reliability. As industries continue to evolve, Rexroth Poppet Valves will remain at the forefront of hydraulic technology, exhibiting unparalleled performance across numerous applications.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!