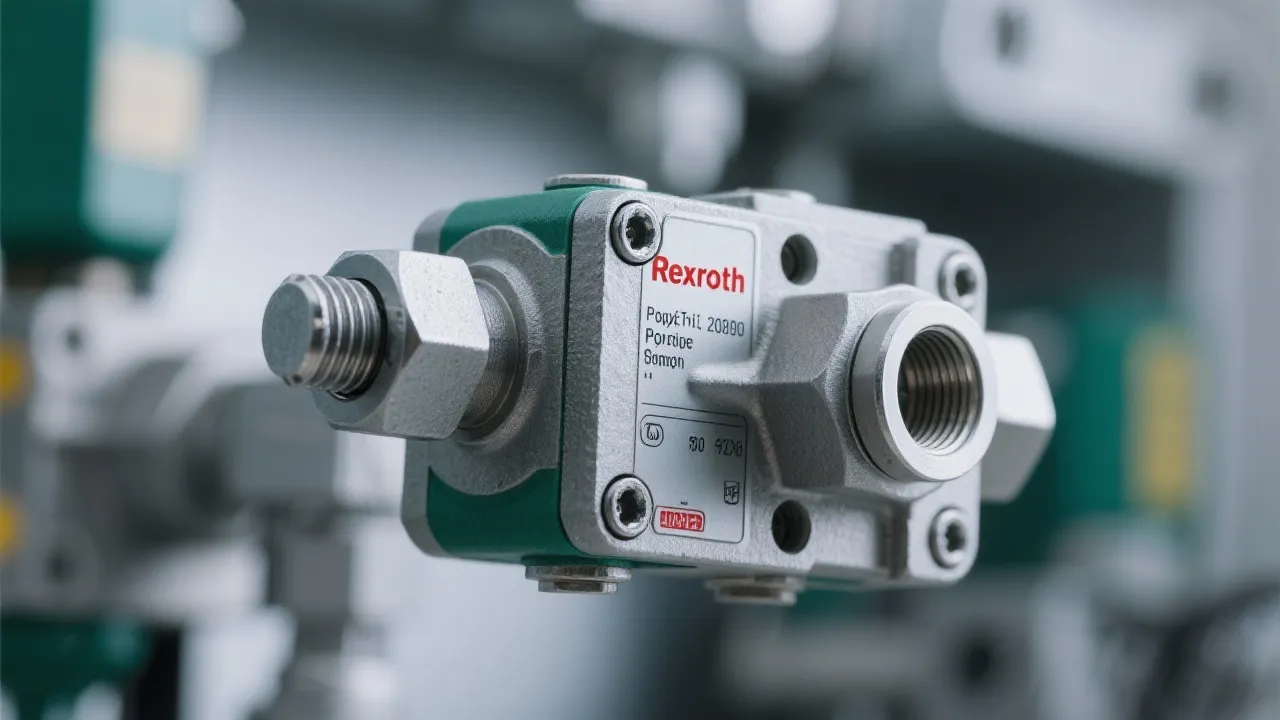

This article explores the importance of Rexroth Poppet Valve systems in industrial and mechanical applications. Known for their precision and reliability, these valves are pivotal in controlling fluid flow in various sectors. Understanding their functioning can aid industries in optimizing operations and enhancing productivity.

Rexroth Poppet Valves are integral components in hydraulic systems, essential for managing the direction, pressure, and flow of fluid within these systems. Renowned for their precision and durability, these valves are widely used in different industrial applications for efficient operation and control. As industries continue to evolve and demand more sophisticated and efficient hydraulic solutions, the role of Rexroth Poppet Valves has become even more significant.

These valves utilize a simple yet effective mechanism to control fluid flow, making them reliable choices for various hydraulic systems. Their unique design allows them to maintain a small footprint while still delivering high performance, which is crucial in space-constrained applications. The engineering behind Rexroth Poppet Valves not only emphasizes functionality but also considers ease of integration into existing systems, further enhancing their versatility across different sectors.

Rexroth Poppet Valves are designed to offer high precision and reliability. They are characterized by their robust construction, which ensures long operational life even under demanding conditions. The valves are efficient in controlling high pressure, which makes them indispensable in industries requiring stringent flow management. Their design minimizes leakage, which is crucial in high-pressure applications where fluid loss can result in significant operational inefficiencies and increased costs.

Additionally, Rexroth Poppet Valves are engineered for quick response times, allowing for immediate adjustments to flow rates as conditions change. This responsiveness is vital in dynamic environments where process requirements can shift rapidly. The ability to fine-tune pressure and flow not only aids in achieving optimal performance but also contributes to the overall safety and longevity of hydraulic systems.

Another notable feature is their adaptability to various control methods ranging from manual to fully automated systems, including remote monitoring capabilities. This flexibility makes them suitable for applications where continuous operation and minimal downtime are critical, particularly in industries such as manufacturing and automation.

These valves find applications in numerous sectors including manufacturing, automotive, and construction. In manufacturing, they help in controlled movement and positioning, ensuring that machinery functions optimally. Here, Rexroth Poppet Valves can regulate actuators, cylinders, and other components, facilitating precise control over manufacturing processes.

In the automotive sector, they are crucial in braking systems where precise fluid control is required to enhance vehicle safety. They enable reliable operation of hydraulic brakes, allowing for better stopping power and increased reliability during emergency situations. Furthermore, their compact size makes them ideal for integrating into various vehicle systems, providing essential functions without compromising space or weight.

In construction, Rexroth Poppet Valves serve an essential role in heavy machinery such as excavators, cranes, and hydraulic lifts, where they control the fluid flow to hydraulic cylinders that drive these machines' movements. Their high-pressure capabilities ensure that such machines can operate efficiently and safely under heavy loads, which is a critical concern in construction environments.

Other industries benefiting from Rexroth Poppet Valves include aerospace and maritime, where the need for lightweight yet durable components is paramount. In these applications, the reliability and efficiency of hydraulic systems directly translate to safety and performance.

The operation of Rexroth Poppet Valves involves the use of a poppet, a disk that seals against a valve seat. When activated, the poppet moves away from the seat, allowing fluid to pass through. This mechanism is governed by the hydraulic pressure acting on the valve, which modulates the flow as necessary. In essence, the valve acts as a gate that either allows or restricts fluid flow based on the requirements of the system.

When there is no hydraulic pressure, the poppet remains seated against the valve seat, providing a tight seal that prevents fluid from leaking through. As fluid pressure increases, it acts on the poppet, pushing it off the seat and allowing flow through the valve body. The design of the valve ensures smooth transitions between open and closed positions, minimizing turbulence and pressure drops, which is critical for maintaining system efficiency.

Moreover, the flow characteristics of these valves can often be tailored to specific applications. For instance, in applications requiring gradual flow control, the poppet design can be adjusted to allow for precision in fluid delivery, which is essential in scenarios like injection molding and food processing where exact fluid volumes are critical.

| Feature | Rexroth Poppet Valve | Conventional Valve |

|---|---|---|

| Precision | High | Moderate |

| Durability | Robust | Standard |

| Pressure Control | Efficient Regulation | Basic Regulation |

| Response Time | Fast | Slower |

| Leakage Rate | Minimal | Higher |

| Compatibility with Automation | High | Moderate |

To ensure the longevity and optimal performance of Rexroth Poppet Valves, proper installation practices must be followed. It is crucial to handle the valves with care during installation to avoid any damage to the components. Avoiding excessive force during installation can help prevent misalignment of the valves, which is often a source of failure.

Regular maintenance checks and cleaning are recommended to prevent any buildup that could impair functionality. Hydraulic fluids can degrade over time, leading to contamination that can adversely affect valve performance. Implementing a maintenance schedule based on the operational conditions and fluid properties helps maintain cleanliness and prolongs life.

In addition to regular inspections, it is also vital to check for signs of wear or damage, especially in high-usage applications. Components should be replaced at the first sign of wear to prevent more significant system failures down the line. Technicians should be trained to identify early signs of valve malfunction and have the procedures for replacing parts or recalibrating as necessary.

Furthermore, it’s recommended to maintain an ideal operating temperature for the hydraulic fluid. Extreme temperatures can reduce fluid viscosity, leading to inefficient valve operation. Utilizing fluid coolers or heaters where necessary can help stabilize the temperature of hydraulic systems, thereby enhancing the efficiency and reliability of Rexroth Poppet Valves.

With advances in technology, the future of fluid control systems, including Rexroth Poppet Valves, looks promising. Innovations are focused on enhancing efficiency and control through smart technology integrations like IoT, which allows for real-time monitoring and adjustments to system pressures and flows. These technologies not only improve operational monitoring but also facilitate predictive maintenance, helping organizations mitigate downtime by addressing issues before they escalate.

The incorporation of smart sensors in Rexroth Poppet Valves could enable self-diagnosis capabilities, where valves can report their operational status and alert maintenance teams to potential issues. Such integration would significantly increase safety and operational reliability in industrial environments where performance is critical.

Moreover, the trend towards automation in industrial processes is likely to demand even more advanced valve solutions. Rexroth Poppet Valves can evolve to meet these demands by incorporating advanced control algorithms that allow for more sophisticated control strategies. This evolution may also lead to the development of modular valve designs that can be customized based on specific operational needs of different industries.

As industries such as renewable energy, aerospace, and robotics continue to grow, the demand for high-performance fluid control components will only increase. Rexroth Poppet Valves are well-positioned to meet these challenges, continuing to advance in their design and operational capabilities to support the evolving needs of modern industrial applications.

Rexroth Poppet Valves are noteworthy for their high precision, reliability, and robust construction, which ensures effective control of hydraulic systems. Their small size combined with high performance allows them to fit into various applications that demand both efficiency and effectiveness, thereby setting them apart from standard valves.

Yes, Rexroth Poppet Valves are designed to efficiently manage high-pressure environments, ensuring optimal performance and safety. They undergo rigorous testing to validate their performance under potentially hazardous conditions and meet the stringent requirements of various industrial standards.

They are extensively used in manufacturing, automotive, and construction industries due to their reliable fluid management capabilities. Additionally, their applications extend to aerospace, marine, and automation industries, highlighting their versatility and adaptability across multiple sectors.

Selecting the appropriate Rexroth Poppet Valve requires assessing the specific needs of your application. Factors like pressure requirements, flow rates, fluid characteristics, and environmental conditions should be considered. Consulting technical documentation and working with experts in fluid dynamics can ensure the best fit for your system's needs.

The evolution of Rexroth Poppet Valves represents a significant advancement in fluid dynamics, ensuring precision in applications that require meticulous control. Their continued development will no doubt lead to even greater efficiencies and reliability, solidifying their place in the future of industrial operations. As we move into a more automated and technologically advanced industrial landscape, the integral role that these valves play will only become more pronounced, emphasizing the importance of investing in high-quality hydraulic components for achieving competitive advantages in various industries.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!