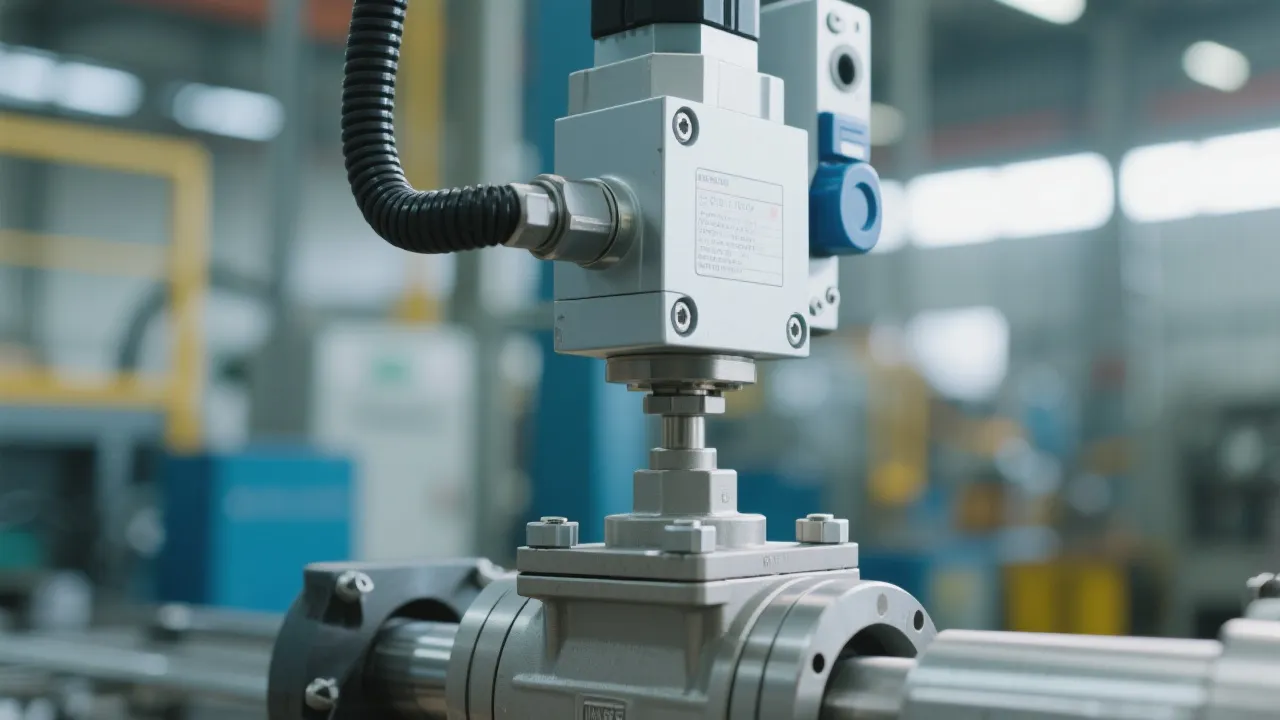

The Rexroth Servo Valve is a pivotal component in advanced hydraulic and pneumatic systems, known for its precision and reliability. These valves enable highly accurate control of fluid dynamics in industrial applications, making them indispensable in sectors like manufacturing and automation. Understanding their function and benefits is crucial for optimizing performance and efficiency in modern industrial processes.

Rexroth Servo Valves are designed for precision control of hydraulic and pneumatic systems utilized in a wide array of industrial applications. These valves are characterized by their remarkable ability to modulate flow and pressure, performing an essential function in the automation sector. Renowned for their reliability and finely tuned performance, Rexroth Servo Valves play a critical role in enhancing the productivity and precision of machinery, particularly in complex manufacturing environments. The high demand in industries such as automotive manufacturing, aerospace, and robotics has led to the evolving design and technology behind these valves, ensuring they meet stringent operational criteria while improving overall system efficiency.

Rexroth Servo Valves stand out due to several intrinsic features, each tailored to meet the rigorous needs of modern industrial operations:

The implementation of Rexroth Servo Valves in industrial settings offers numerous advantages, addressing specific challenges across various sectors:

| Feature | Rexroth Servo Valve | Competitor B |

|---|---|---|

| Precision | Highly precise control, suitable for complex operations requiring tight tolerances. | Moderate precision, often requires additional calibration for optimal performance. |

| Durability | Extended service life with minimal maintenance due to robust construction and quality materials. | Standard durability, resulting in higher wear and potential failures over time. |

| Customization | Wide range of customization options are available, including specific flow rates and pressure responses. | Limited customization, mainly reliant on standard models that may not fit all application needs. |

| Response Time | Quick response to control signals, improving the efficiency of dynamic systems. | Slower response time, potentially hindering the speed of operations. |

Industries such as manufacturing, aerospace, automotive, marine, food processing, and robotics benefit significantly from the application of Rexroth Servo Valves due to their need for precise hydraulic and pneumatic control.

These valves optimize flow and pressure regulation, reducing unnecessary power usage and thereby lowering energy consumption. This leads to significant cost savings in industrial operations, aligning with broader sustainability initiatives.

Yes, Rexroth Servo Valves can be easily integrated into existing hydraulic or pneumatic systems. Their versatile configurations and adaptability to various control systems make them an excellent choice for upgrades or replacements in legacy systems.

While Rexroth Servo Valves are designed for longevity, regular maintenance is essential for optimal performance. This includes periodic inspections for wear, ensuring that filters are clean, and checking for any hydraulic fluid contamination. Employing automated diagnostic tools can help streamline the maintenance process.

Recent technological advancements include the incorporation of IoT capabilities for remote monitoring and diagnostics, along with enhancements in material science that lead to lighter and more durable valve constructions. This transformation not only enhances performance but also helps in reducing environmental impact.

The expected service life of Rexroth Servo Valves can vary based on application, operating conditions, and maintenance routines, but many units are designed to last for years, often exceeding 10,000 operational hours in typical industrial environments.

Rexroth Servo Valves represent a cornerstone in the domain of industrial automation, effectively combining cutting-edge technology with adaptable engineering to meet the evolving demands of modern industry. Their widespread applicability across various sectors underscores their importance in contemporary industrial operations. For enterprises looking to maximize efficiency, minimize downtime, and ensure precision in their manufacturing and operational processes, the integration of such advanced control components is not just beneficial but essential.

The future of Rexroth Servo Valves and similar technologies is poised for significant transformation driven by ongoing research and advancements in automation and control systems. As industries increasingly demand smarter solutions, the integration of artificial intelligence (AI) and machine learning within servo control systems will emerge as a focal point. These technologies can enable predictive maintenance, whereby systems can learn and anticipate failures before they happen, streamlining maintenance schedules and reducing unexpected downtimes.

Additionally, as the world shifts towards more sustainable practices, servo valve technology will likely incorporate eco-friendly materials and processes that ensure efficiency without compromising environmental integrity. The rise of Industry 4.0—characterized by connectivity, big data, and cumulative intelligence—will play a crucial role in the development of future servo valve designs, enabling real-time data analytics and stewardship across various applications. Manufacturers will prioritize creating products that are not only functional but also contribute positively to the global sustainability agenda.

As technology progresses, the algorithms used to control Rexroth Servo Valves are also evolving. Traditional models primarily focused on PID (Proportional-Integral-Derivative) control strategies, but more innovative approaches involving fuzzy logic, adaptive control, and even neural networks are beginning to gain traction. These contemporary control methods enhance system responsiveness and adaptability, ultimately allowing for improved performance in varying operational conditions.

Moreover, intelligent control systems that utilize advanced computational techniques can optimize the valve's operation over time, learning from past performances and environmental variables to adjust parameters automatically. This paradigm shift will result in increased efficiency, reduced wear on components, and higher throughput in manufacturing settings.

In summary, the evolution of Rexroth Servo Valves is not merely about enhancing existing features; it also involves rethinking how we approach automation and control in the industrial landscape. With a commitment to innovation and excellence, those employing these technologies will remain at the frontier of industrial efficiency and productivity.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!