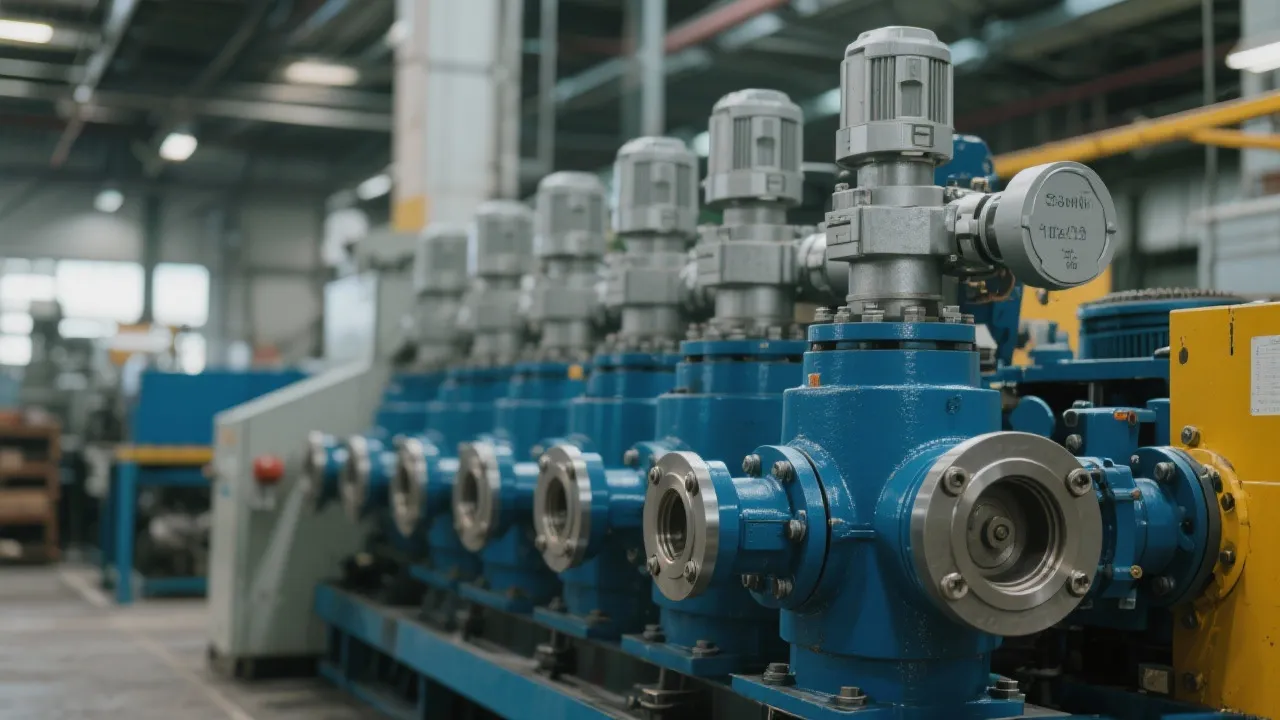

Rexroth Cartridge Valves are critical components in hydraulic systems, offering precise control and reliable performance. Made by Bosch Rexroth, a leader in industrial technology, these valves are integral for applications ranging from mobile machinery to factory automation. Known for their innovative design, they improve efficiency and reduce energy consumption in demanding environments.

In the world of industrial engineering, hydraulic systems play a pivotal role in delivering power and precision across various applications. At the heart of these systems, components like Rexroth Cartridge Valves provide essential control, ensuring operational efficiency and reliability. Understanding how hydraulic systems function and the role these components play can greatly enhance their application and usability.

Produced by Bosch Rexroth, a renowned leader in the field of industrial automation, Rexroth Cartridge Valves are designed to meet the demanding requirements of modern hydraulic systems. These valves regulate hydraulic fluids, enabling precise control over machinery movements, a vital aspect of operations in industries such as manufacturing, construction, and agriculture. The technology behind these valves is rooted in advanced engineering that emphasizes modularity, precision, and integration capabilities. Each cartridge valve functions independently yet can work seamlessly within a larger hydraulic assembly, making installation and upgrade processes more straightforward.

The design of Rexroth Cartridge Valves features a compact, modular structure, which facilitates easy integration into existing systems. One of their key characteristics is the ability to withstand high pressure while maintaining smooth operation, thereby increasing the lifespan of the system and minimizing maintenance needs. Furthermore, their innovative design reduces energy consumption, a critical factor in today's energy-conscious environments. The valves utilize advanced materials that not only add to their strength but also improve their resistance to corrosion and wear, which are common factors in hydraulic systems that operate under extreme conditions.

Rexroth Cartridge Valves are utilized in a wide array of applications, ranging from mobile machinery like excavators and harvesters to stationary industrial equipment within factories. Their versatility and adaptability make them ideal choices for systems requiring precise control under rigorous conditions. For instance, in construction machinery, these valves help manage the forces exerted by hydraulic cylinders, allowing for precise control of arms, booms, and swinging actions. In agricultural equipment, they facilitate accurate control during planting, harvesting, and other processes essential for crop production.

Besides construction and agriculture, Rexroth Cartridge Valves find applications in sectors such as robotics, aerospace, and even maritime. In robotics, the valves enable fine motor control for robotic arms used in assembling products or performing intricate surgical operations. In aerospace, they contribute to flight control systems and landing gear management, where reliability is paramount due to the safety implications involved. Thus, the versatility of these valves makes them a valuable component in almost any industry utilizing hydraulic systems.

Some of the standout benefits of using Rexroth Cartridge Valves include:

Installing Rexroth Cartridge Valves requires precision and expertise to ensure optimal performance. This process is detailed and critical, as improperly installed valves may lead to system failures or suboptimal operations. It is essential that technicians have proper training and knowledge of hydraulic systems. Regular maintenance helps preserve their functionality, with routine checks recommended to prevent leaks and ensure smooth fluid flow. Proactive maintenance reduces the likelihood of unscheduled downtime, thus enhancing productivity within the work environment.

Industries such as manufacturing, construction, and agriculture gain immense benefits from these valves due to their need for precise hydraulic control and durability. Further, sectors like military engineering, robotics, and heavy vehicle operations also rely heavily on these valves for optimal performance and reliability.

The advanced design of these valves reduces energy loss during fluid control, as their construction ensures that minimum resistance is offered to fluid flow, thereby requiring less power to achieve the desired control levels.

While highly versatile, it is essential to check specifications for compatibility with the existing system design. Factors like fluid type, pressure rating, and system size significantly influence compatibility.

The lifespan of Rexroth Cartridge Valves can vary significantly based on usage and maintenance practices. Regular monitoring and maintenance can extend their service life, but a general guideline suggests replacement every 5 to 10 years, depending on the service conditions.

In the event of a valve failure, immediately shut down the hydraulic system to prevent further damage. Then, assess the type of failure—whether it be leaking, malfunctioning or another issue. Consult with a specialized technician if replacement or repairs are required, following up with a thorough inspection and service of the entire hydraulic system to mitigate future risks.

Rexroth Cartridge Valves stand as a testament to the innovative engineering from Bosch Rexroth, providing unmatched reliability and performance in hydraulic systems. Their contribution to efficiency, durability, and cost-effectiveness makes them indispensable components in a wide range of industrial applications. As industry needs evolve, the importance of advanced hydraulic technologies like these valves will only become more pronounced, guiding us towards smarter, more energy-efficient solutions. Their continued adaptation and improvement will further solidify their vital role in both existing and emerging markets, ensuring that hydraulic systems respond to increasingly complex challenges in an efficient and sustainable manner.

Going forward, the evolution of hydraulic technology is expected to pave the way for even more sophisticated applications of Rexroth Cartridge Valves. The intersection of hydraulics with digital technologies, often referred to as Industry 4.0, will allow for greater automation and smarter control mechanisms. Innovations like predictive maintenance fueled by IoT (Internet of Things) will help in data collection from hydraulic systems. This real-time monitoring will facilitate proactive responses to system performance issues, enhancing operational efficiency and significantly reducing downtime.

As industries increasingly embrace digital transformation, Rexroth Cartridge Valves will likely incorporate smart sensors that can relay information about performance metrics, fault conditions, and overall system integrity. This integration can lead to improved decision-making processes, not just in individual operations but across entire facilities. The capability to analyze data collected from multiple hydraulic systems will enable businesses to optimize their operations further while adhering to sustainability standards. The trend towards a more connected world highlights the critical importance of reliability, efficiency, and adaptability, which Rexroth Cartridge Valves inherently provide.

Sustainability is another key area where the design of Rexroth Cartridge Valves has notable significance. By effectively managing hydraulic fluid flows, these valves contribute to minimizing waste and energy loss. As manufacturers shift focus towards reducing their carbon footprints, the energy-efficient deployment of hydraulic systems equipped with such valves becomes even more critical. Furthermore, efficiently designed hydraulic systems lead to lower oil consumption and waste generation, creating a more sustainable operational environment.

To appreciate the advancements brought about by products like Rexroth Cartridge Valves, it is helpful to consider the historical significance of hydraulic systems as a whole. The use of hydraulics dates back to ancient civilizations, with early examples found in watermills and aqueduct systems. Over the centuries, hydraulic technology has evolved dramatically—from simple water-powered devices to complex systems that form the backbone of modern machinery and automation. The ongoing improvements in hydraulic valve technology reflect a continuous pursuit of efficiency, control, and reliability that addresses the ever-increasing demands of industrial applications.

Given the complexity associated with hydraulic systems and the use of components like Rexroth Cartridge Valves, proper training and certification for technicians are vital. Access to educational resources, hands-on training, and workshops can significantly enhance engineers' and technicians' skills. Companies investing in training programs not only improve their workforce's expertise but also contribute to the longevity and effectiveness of their hydraulic systems. This alignment of training with technological advancements ensures that organizations can remain competitive in a rapidly evolving market.

The continual development of hydraulic technology and the incorporation of innovative products like Rexroth Cartridge Valves have far-reaching implications for countless industries. This progress will foster higher efficiency, enhanced performance, and the capacity to meet stringent environmental standards. As hydraulic systems become smarter and more integrated into the modern industrial landscape, the future will undoubtedly shine brightly on these essential components. From machine automation to advanced robotic applications, the journey of Rexroth Valve technology is poised to expand, adapting to the requirements of a high-tech future and solidifying their role as industry leaders.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!