Polysulfide adhesive is a highly durable, flexible sealant used predominantly in the aerospace and construction industries. Known for its excellent resistance to chemicals, temperature extremes, and aging, polysulfide adhesive is an ideal choice for applications requiring long-lasting and reliable seals.

Polysulfide adhesive is recognized for its versatility and exceptional properties, making it a staple in various industrial applications. Particularly valued in aerospace, construction, and marine industries, this adhesive offers unmatched durability and flexibility. Its resistance to chemicals, water, and weathering ensures long-lasting performance, essential for demanding environments. The backbone of polysulfide adhesives lies in their unique polymer structure, which contributes to their remarkable characteristics that set them apart from alternative adhesive solutions. Understanding the chemistry behind polysulfide adhesives can provide insight into their behavior and applications, making it easier for users to choose the right adhesive for their specific needs.

The name "polysulfide" is derived from the polymer chain structure, which includes alternating sulfur atoms linked to other elements in the backbone. This unique chemistry allows polysulfide adhesives to maintain flexibility while providing superior sealing and bonding capabilities. The polymerization process involves the reaction of diisocyanates with alcohols, resulting in the formation of polysulfide chains. Throughout the curing process, the material transitions from a viscous liquid into a flexible, rubber-like solid that exhibits exceptional performance under various conditions. This reaction is what gives these adhesives their incredible resilience against environmental stresses.

Polysulfide adhesive is known for its high flexibility, which allows it to absorb movement without compromising its seal. This characteristic makes it ideal for sealing joints and seams in structures subject to vibrations and temperature fluctuations. Additionally, its formidable resistance to chemicals ensures that it remains effective in harsh environments where other adhesives might deteriorate. From acidic substances to alkaline conditions, the ability of polysulfide adhesives to resist chemical attack significantly enhances their application range.

Another significant advantage is its weatherproof nature. Polysulfide adhesives do not crack or degrade when exposed to UV light, rain, or temperature extremes, making them perfect for outdoor applications. Their impermeability to water and moisture further enhances their suitability for marine and underwater applications. Furthermore, the low permeability to gases means that polysulfide adhesives can help maintain structural integrity even in environments with fluctuating pressure conditions, such as in aerospace and marine applications.

One of the primary users of polysulfide adhesives is the aerospace industry. These adhesives are employed in aircraft assembly and repairs, particularly because of their ability to withstand the wide temperature ranges and pressures aircraft are subjected to. They seal fuel tanks, wings, and windshields, ensuring safety and performance. For instance, polysulfide sealants are crucial in preventing fuel leakage in critical aircraft components, which could lead to catastrophic failures if unaddressed. As aircraft are often exposed to extreme altitude conditions and temperature variations, using the right adhesive is paramount for ensuring operational safety.

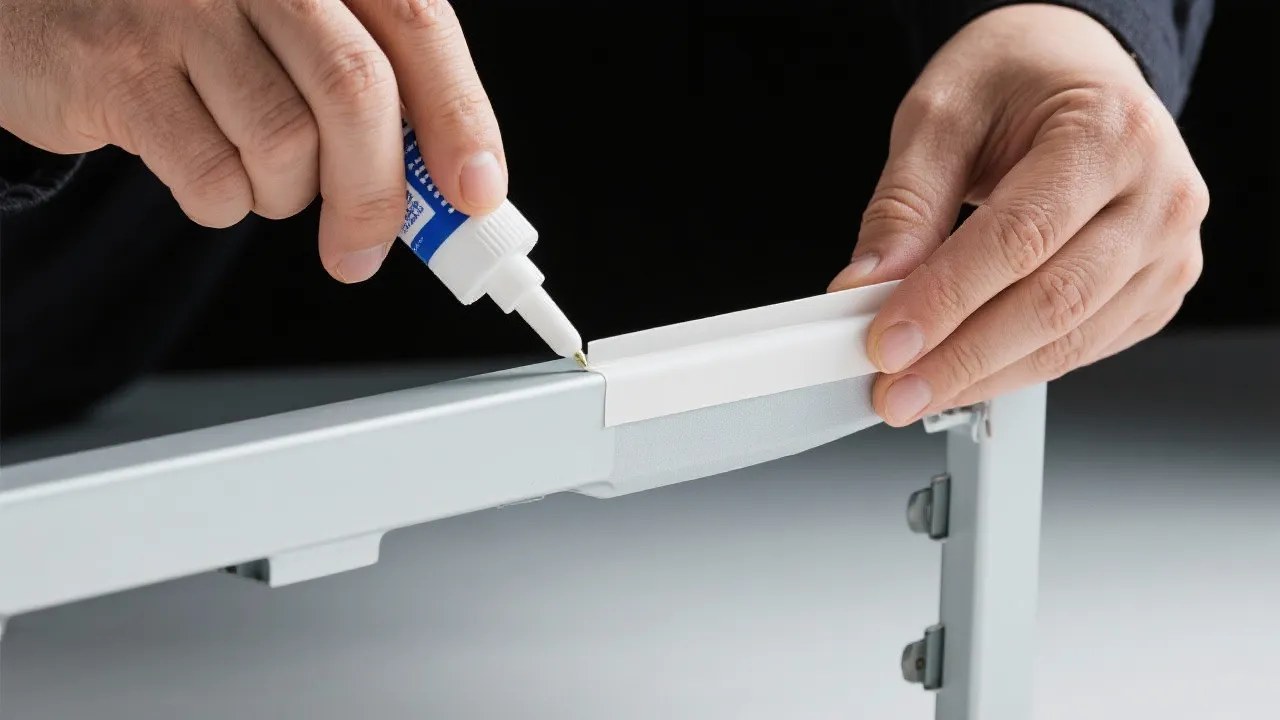

In the construction sector, polysulfide adhesives are applied in glazing projects, sealing windows and structural facades to prevent leaks and enhance building longevity. They also find use in sealing industrial flooring and roofs, where their robustness ensures longevity despite constant exposure to environmental factors. In commercial construction, polysulfide adhesives are regularly used in assembling prefabricated sections, allowing for precise alignments, stress distribution, and waterproofing capabilities, thus prolonging the lifespan of the building components.

The marine industry significantly benefits from polysulfide adhesives due to their resistance to water and salt conditions. In shipbuilding, these adhesives provide reliable sealing for hulls and decks, ensuring that water ingress is minimized. As vessels traverse harsh ocean conditions, the structural integrity maintained by polysulfide adhesives becomes essential not only for performance but also for the safety of the crew and cargo. Furthermore, the adhesive's resilience against fungal and microbial growth makes it suitable for underwater applications, where traditional adhesives would fail.

Polysulfide adhesives are also making inroads into the automotive industry. They are employed for bonding windshields and sealing areas that are subject to movement and require high flexibility. The automotive sector benefits from the adhesive’s chemical resistance, especially against fuels, oils, and other liquids commonly found in vehicle operation. As electric vehicles become more prevalent, using lightweight and durable materials keeps vehicles efficient while ensuring that necessary seals, such as for battery compartments and motor housings, are effective and strong.

According to industry reports, the demand for polysulfide adhesives has been on a consistent rise, attributed to the growing aerospace sector and infrastructural developments globally. The adhesive's ability to adhere to various substrates and resist environmental degradation makes it a favored choice across industries. The increasing focus on safety and sustainability in manufacturing processes has also led businesses to adopt adhesives that not only perform but also align with regulatory environments.

As the world shifts towards more sustainable building practices and innovative aerospace technologies, the reliance on resilient materials such as polysulfide adhesives is expected to grow. With continuous research and development, these adhesives are becoming more efficient, maintaining their place as an essential component in critical applications. Innovative formulations are being introduced that enhance their performance further, such as improving their cure times and initiating processes, which reduce manufacturing times while maintaining superior quality.

In recent years, there has been an increasing emphasis on sustainability and environmental considerations in adhesive manufacturing. Polysulfide adhesives, while traditionally based on petrochemical resources, are being evaluated to incorporate more sustainable materials or biopolymers in their production. This shift not only caters to a growing demand for “green” products but also adheres to stricter regulations concerning volatile organic compounds (VOCs) and overall environmental impact.

Additionally, the development of smart adhesives that can signal when they are no longer effective, by changing color or texture, offers exciting prospects for industries concerned with maintenance and safety. These innovations could fundamentally change how polysulfide is used, paving the way for advanced applications in high-tech sectors.

Furthermore, ongoing research into modifying the chemical properties of polysulfide adhesives could allow for even broader applications, including in the realms of bioengineering and space exploration. These advanced products could find use in scenarios where extreme performance is a necessity, opening new markets for polysulfide adhesives.

Polysulfide adhesive continues to be a pivotal player in industries that require robust, durable, and reliable sealing solutions. Its distinct properties make it an invaluable tool for professionals who demand excellence in performance, longevity, and adaptability. As advancements in technology and industry applications evolve, the use and refinement of polysulfide adhesive are likely to expand, ensuring its relevance in future developments. Professionals across various sectors benefit from understanding the specific capabilities, advantages, and potential applications of polysulfide adhesives, ultimately allowing them to make informed decisions about the materials used in their processes.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!