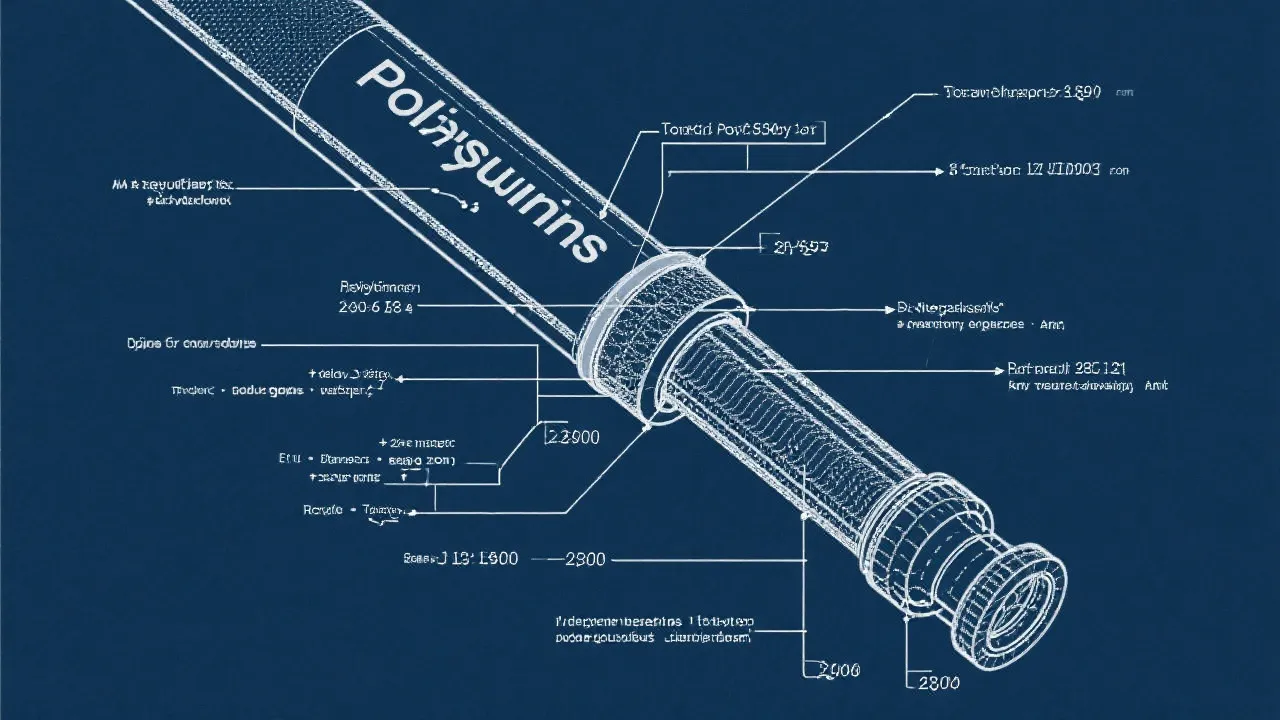

Polysulfide adhesive is a versatile sealing and bonding material known for its excellent chemical resistance and flexibility. It is widely used in industries requiring robust and enduring sealants, such as aerospace, construction, and marine applications. This article delves into the properties, applications, and advantages of using polysulfide adhesive in various industrial sectors.

Polysulfide adhesive is a prominent player in the industrial sealant market, recognized for its durability and exceptional resilience to harsh environments. This type of adhesive is valued for its ability to withstand a wide range of temperatures, its resistance to chemicals, and its flexibility, making it an ideal choice for industries where robust sealing solutions are required. Polysulfide adhesives derive their strength from a unique chemical structure that allows for the formation of strong covalent bonds, which contribute to their durability and longevity. This introduction to polysulfide adhesives provides a foundational understanding of their characteristics, applications, advantages, and the challenges they may present in various industrial settings.

Polysulfide adhesives are formulated with a synthetic polymer known for its sulfur cross-linking backbone. This unique composition imparts several beneficial properties, such as durability and elasticity, even under varying temperature conditions. These adhesives exhibit exceptional resistance to solvents, oils, and UV light, making them suitable for outdoor and marine environments. An added benefit of polysulfide adhesives is their low permeability to gases and liquids, which ensures that they create tight seals that prevent leakage. This property is particularly critical in applications where preventing the ingress of moisture or other contaminants is essential.

Another characteristic feature of polysulfide adhesives is their excellent adhesion to a variety of substrates. They can bond effectively to metals, glass, wood, and plastics without significant surface preparation, which can often simplify the application process. The adhesion performance can be enhanced further by using primers or surface cleaners, depending on the conditions and materials involved.

The versatility of polysulfide adhesive allows it to be utilized in numerous industrial applications:

One of the primary advantages of polysulfide adhesive is its ability to form strong, flexible bonds that can endure movement and stress without losing adhesion. This feature is crucial in applications that experience thermal expansion and contraction. Moreover, its chemical resistance ensures longevity in applications where exposure to harsh substances is commonplace, such as fuels or aggressive environmental conditions. The elasticity of the adhesive also provides excellent vibration damping properties, further adding to its versatility in challenging environments.

Furthermore, polysulfide adhesives can withstand both high and low temperatures, which is why they are employed in various applications, from cryogenic environments in aerospace to high-heat situations in manufacturing processes. Their multifunctionality also means that they can be used in different phases of manufacturing, including as a bonding agent, sealant, or protective coating.

Finally, polysulfide adhesives do not shrink significantly upon curing, which helps maintain bond integrity over time and reduces the likelihood of stress-induced failures at the joints of bonded materials. This stability is vital in maintaining the overall strength and effectiveness of seals in critical applications.

While polysulfide adhesive offers numerous benefits, certain challenges must be addressed during its application. The curing time can be relatively long compared to other adhesives, requiring careful planning in fast-paced production environments. Depending on the specific formulation, curing can take anywhere from a few hours to several days, and this must be factored into project timelines. Additionally, precise mixing and application are crucial to achieve the optimal performance expected from polysulfide adhesives; improper ratios can lead to either an ineffective bond or a failure to cure correctly.

Storage conditions also play an essential role in the shelf life and effectiveness of polysulfide adhesives. They should be stored in a cool, dry place and used within the recommended timeframe to avoid degradation of their properties. Moreover, polysulfide adhesives may require specialized tools for application, as they can be more viscous than other common sealants and may not work well with standard caulking guns.

Environmental factors during application also need to be assessed. High humidity or low temperatures can affect the curing process, necessitating controlled application conditions to guarantee reliable bonding. Careful adherence to manufacturers' guidelines regarding environmental conditions can mitigate these issues, ensuring that performance expectations are met. Additionally, proper personal protective equipment should always be utilized during application to handle the chemicals involved safely.

The world of adhesives is continually evolving as manufacturers seek ways to improve the performance, sustainability, and application methods of their products. Polysulfide adhesives are no exception, and several trends are emerging that could shape their future use across various industries:

1. Increased Sustainability: As many industries face pressure to adopt more sustainable practices, there is a growing trend towards developing eco-friendly polysulfide formulations. Companies are researching alternatives to traditional solvents and starting to incorporate greener raw materials into their polysulfide adhesives while maintaining performance standards.

2. Enhanced Formulations: Research and development efforts are focusing on enhancing the properties of polysulfide adhesives. Manufacturers are working on creating formulations with faster curing times, improved bond strengths, and even better resistance to specific environmental factors. Such enhancements would further widen their application scope and increase their competitiveness against other adhesive chemistries.

3. Smart Adhesives: The integration of technology into adhesive formulations is on the rise. Smart adhesives embed sensors that can monitor factors such as temperature and stress in real-time. This capability could lead to the development of polysulfide adhesives that can signal when a bond may fail due to extreme conditions, helping operators take preventative action before catastrophic failures occur.

4. Bio-Based Developments: The rise in biopolymer research may influence the future of polysulfide adhesives. Bio-based polysulfides could emerge as an alternative, helping to reduce reliance on petrochemical products while still offering the high-performance properties needed in industrial applications.

5. Training and Best Practices: As the adhesive industry evolves, the importance of proper application techniques and training will be paramount. Manufacturers may increasingly offer comprehensive training programs to ensure that end-users are capable of applying polysulfide adhesives effectively, minimizing the issues traditionally linked to the curing processes and environmental factors.

In conclusion, polysulfide adhesive represents a key material in industrial applications where durability, chemical resistance, and flexibility are critical. Its diverse application across industries, from aerospace to construction, highlights its importance as a reliable sealing solution in demanding environments. The future of polysulfide adhesives appears promising, supported by advances in technology that prioritize sustainability, performance enhancements, and user education. When applied correctly and in the right context, these adhesives can provide long-lasting, resilient solutions that meet the rigorous demands of modern industrial applications. With ongoing research and development, we can expect to see even broader levels of innovation and adaptation in the polysulfide adhesive market, ensuring its continued relevance for years to come.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!