Polysulfide adhesive is a versatile sealing solution known for its durability and flexibility. Typically used in industrial and construction applications, it offers excellent chemical resistance and weatherability, making it ideal for environments exposed to harsh conditions. This article delves into the properties, applications, and benefits of polysulfide adhesives, providing insights for industry professionals.

In the landscape of industrial adhesives, polysulfide adhesive stands out for its unique properties and versatility. As a cornerstone of both construction and manufacturing industries, this adhesive is renowned for its strength and adaptability. Understanding its applications and advantages can empower professionals in making informed decisions that enhance durability and efficiency. Polysulfide adhesives are synthetic polymers that are formed by the chemical reaction of a polysulfide polymer with a curing agent, which results in a rubbery product that retains certain mechanical and chemical properties even under extreme conditions. Their formulation typically includes plasticizers, fillers, and additives to improve properties such as adhesion, workability, and curing time, thereby making them suitable for a variety of applications.

Polysulfide adhesive is extensively used in various sectors. Here are some key applications:

| Adhesive Type | Durability | Chemical Resistance | Flexibility |

|---|---|---|---|

| Polysulfide | High | High | High |

| Silicone | Medium | Medium | High |

| Polyurethane | High | Low | Medium |

| Epoxy | Very High | Medium | Low |

The comparative analysis above highlights the robust properties of polysulfide adhesives, placing them alongside or above other widely used adhesives in many sectors. Each adhesive type has specific advantages that may make them suitable for different applications, however, the versatility of polysulfide adhesive makes it a preferred choice for demanding environments.

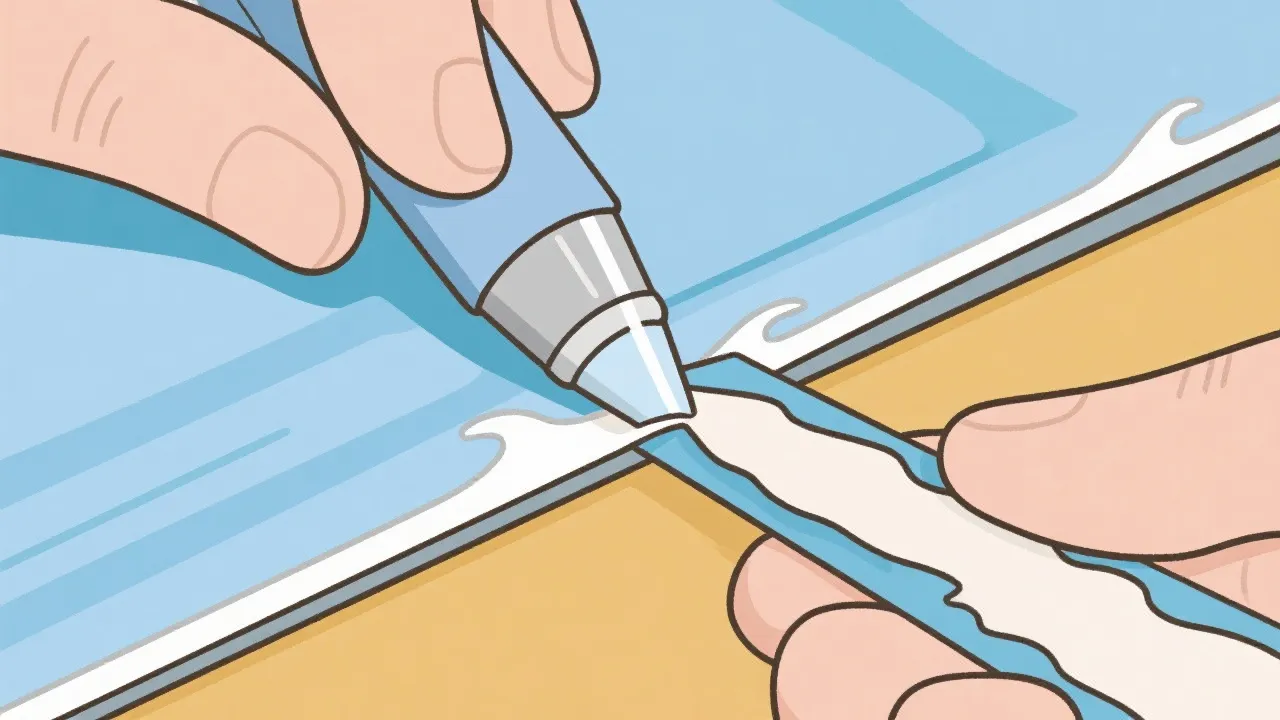

For optimal results, follow these steps when applying polysulfide adhesive:

The field of polysulfide adhesives has been evolving, with new formulations and technologies emerging to improve performance and sustainability. These advancements may include:

Its flexibility and resistance to a wide range of chemicals make it suitable for demanding environments. This versatility allows it to accommodate movement and resist degradation in harsh conditions, which is often a limitation with other sealants.

Yes, particularly in areas requiring waterproofing and flexibility, such as windows, roofs, and bathrooms. Its ability to form a long-lasting seal while resisting moisture makes it ideal for residential use.

While traditional polysulfide adhesives may contain chemicals that could be harmful, many manufacturers are producing eco-friendly versions with reduced impact on human health and the environment. Always refer to the product datasheet for specific environmental and safety information, compliance with local regulations, and certifications.

Polysulfide adhesives bond well to various materials including metal, glass, wood, concrete, and plastics. However, compatibility should be tested, especially for unique or sensitive substrates.

Store in a cool, dry place away from direct sunlight. Ensure the containers are tightly sealed to prevent moisture ingress, which could adversely affect the adhesive properties.

Polysulfide adhesive represents a robust solution for industries requiring a dependable sealant capable of withstanding harsh conditions. Whether utilized in aerospace, construction, marine, or automotive sectors, its properties ensure its status as an indispensable tool for professionals. As technologies evolve, polysulfide adhesives continue to offer reliable performance and enhance the safety and longevity of structures worldwide. Through understanding its features and applications, industries can foster innovation while ensuring structural integrity and sustainability. By making informed decisions regarding the selection, application, and maintenance of polysulfide adhesives, stakeholders can significantly improve project outcomes and extend the lifecycle of their assets.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!