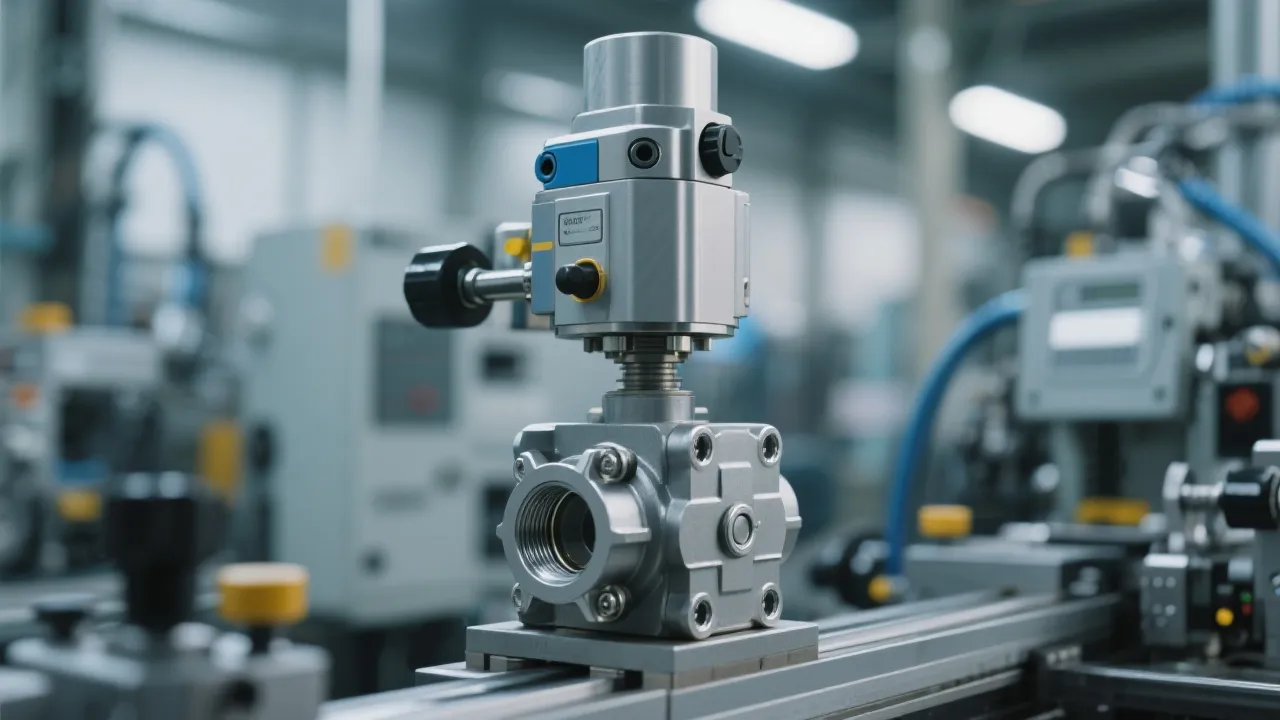

Rexroth Servo Valves are critical components in modern automation and hydraulic systems, renowned for their precision and reliability. These valves play a vital role in controlling fluid flow and pressure, ensuring accurate and dynamic responses in various industrial applications. This article delves into the mechanics, applications, and benefits of utilizing Rexroth Servo Valves in today's technologically advanced environments.

In the realm of modern industrial automation, precision and reliability are paramount. Rexroth Servo Valves stand out as a testament to innovation and engineering prowess, offering unparalleled performance in fluid and pressure control. These valves are integral to a myriad of applications, ranging from manufacturing to aerospace, demonstrating adaptability and precision in environments that demand accuracy and control. The advancements in servo valve technology have made them an essential component in systems requiring high performance and low maintenance. As industries continue to evolve, Rexroth Servo Valves have become synonymous with quality and efficiency, providing solutions that meet the rigorous demands of today's fast-paced production environments.

At the core of the Rexroth Servo Valve's functionality is its ability to precisely control the flow and pressure of fluids within a hydraulic system. These valves utilize intricate electronic feedback mechanisms that adjust the valve position with high accuracy, enabling responsive and dynamic control. The technology behind these devices incorporates state-of-the-art sensors and actuators, ensuring that adjustments are made in real-time to maintain optimal system performance. The feedback mechanisms typically involve position sensors that detect the exact position of the valve spool, while servo motors adjust the spool based on the signals received. This closed-loop control system significantly enhances the precision of fluid delivery, catering to various applications that demand tight tolerances.

Furthermore, Rexroth Servo Valves are designed to handle a wide range of pressures and flows, making them suitable for both low and high-capacity systems. The selection of materials and designs minimizes friction and enhances responsiveness, allowing for rapid changes in flow and pressure. This capacity for quick response times is crucial in applications where delay can lead to significant operational issues. For example, in CNC machining centers, the exact timing and control of hydraulic actuators are critical to achieving the desired precision in cutting processes. Thus, the inherent design of Rexroth Servo Valves allows them to support the burgeoning demands of fast, accurate, and reliable operation.

Rexroth Servo Valves are employed across various sectors due to their versatility and precision. In automotive manufacturing, these valves are utilized for tasks requiring meticulous fluid control, such as in the paint application process. The automotive industry operates with strict standards for surface quality; hence, the consistent and fine control of paint application can significantly influence production efficiency and product quality. Similarly, in aerospace engineering, the valves ensure the accurate and safe operation of hydraulic systems that control aircraft components. Hydraulic systems in airplanes must operate flawlessly under extreme conditions, and Rexroth Servo Valves provide the reliability necessary in these high-stakes environments.

Additionally, industries like oil and gas, metalworking, power generation, and even medical fields benefit from the precise operation provided by these valves, highlighting their indispensable role in complex industrial operations. For instance, in the oil and gas sector, controlled flow rates are necessary for processes such as drilling and refining, where precise pressure control is crucial to ensure safety and efficiency. In manufacturing contexts, such as robotics assembly lines, Rexroth Servo Valves allow for precision in movements that translate into higher throughput rates and better quality control. Each application demonstrates the valvular technology's adaptation to meet specific operational challenges, thus emphasizing its significance across diverse industry standards.

The integration of Rexroth Servo Valves in industrial systems offers numerous advantages. Key benefits include enhanced precision in fluid control, improved efficiency, and reduced energy consumption. The valves’ design minimizes leakage and wear, extending the lifespan of hydraulic systems and reducing maintenance costs. Additionally, the implementation of advanced control algorithms allows for optimization of processes, resulting in less waste and greater overall productivity. Furthermore, their capability to adapt to different operational demands makes them a versatile tool in achieving optimal performance.

With the growing emphasis on sustainability, businesses are increasingly looking to improve energy efficiency within their operations. Rexroth Servo Valves contribute to this goal by regulating flow with high precision, leading to lower energy consumption compared to traditional valve designs. This not only reduces operational costs but also supports corporate sustainability efforts. For example, in a manufacturing setup, energy-efficient hydraulic systems using Rexroth Servo Valves can lead to significant reductions in carbon footprint, aligning with environmental regulations and enhancing the company’s overall image.

| Feature | Description |

|---|---|

| Precision Control | Provides accurate positioning and flow control through advanced electronics, allowing for minute adjustments in real time. |

| Durability | Constructed with materials that ensure long-lasting performance under high pressure and extreme conditions, decreasing the frequency of replacements. |

| Energy Efficiency | Reduces energy consumption by optimizing hydraulic operations; this not only cuts costs but contributes to environmental sustainability goals. |

| Versatility | Adaptable to various industrial applications, from manufacturing to aerospace, making them suitable for both high-speed and high-precision tasks. |

| Feedback Mechanisms | Employs advanced feedback systems for real-time monitoring and adjustment of flow, ensuring consistent operational efficiency. |

Despite their numerous advantages, the use of Rexroth Servo Valves requires careful consideration of system compatibility and operational requirements. Proper installation and alignment are critical to ensure optimal performance, and regular maintenance is necessary to prevent system malfunctions. Misalignment or improper installation can lead to inefficiencies, increased wear, and can even cause system failures that result in costly downtime and repairs. Therefore, investing in proper training for technicians tasked with valve installation and maintenance can pay dividends in long-term operational success.

Additionally, understanding the specific needs of your application environment is crucial in selecting the appropriate valve configuration. Factors such as fluid type, temperature ranges, and pressure specifications must be meticulously analyzed to ensure compatibility. The need for thorough application analysis is particularly important in industries with fluctuating operational conditions, such as those found in the oil and gas sector, where varying pressures and flow rates can demand a reevaluation of the equipment used. Rexroth offers extensive documentation and customer support that aids users in making informed decisions, further enhancing the value proposition of these advanced valves.

What industries benefit most from Rexroth Servo Valves?

Industries such as automotive, aerospace, oil and gas, and manufacturing find significant benefits from using Rexroth Servo Valves due to their need for precision and effective fluid control. They are also widely utilized in sectors such as robotics, manufacturing automation, and process control, where high accuracy and reliability are of utmost importance.

How do Rexroth Servo Valves improve system efficiency?

These valves enhance efficiency by providing precise control, minimizing energy waste, and reducing the need for frequent maintenance due to their durable construction. Improved system efficiency translates into lower operational costs and enhanced productivity, which is critical for businesses aiming to remain competitive in today's market.

Are Rexroth Servo Valves compatible with all hydraulic systems?

While generally compatible, it is essential to ensure that your system meets the specific requirements and standards for which Rexroth Servo Valves are designed to maximize their performance and lifespan. Compatibility checks may include reviewing operating pressures, fluid compatibility, and size specifications to minimize the risks posed by mismatched components.

What maintenance practices are recommended for Rexroth Servo Valves?

Regular maintenance practices may include routine inspections of seals and hoses, checking for leaks, and ensuring that the electronic components are free of dust and debris. Additionally, performing diagnostics and calibration checks will ensure the valve operates within expected parameters, thus prolonging service life and maintaining system performance.

Can Rexroth Servo Valves be used in extreme environments?

Yes, many Rexroth Servo Valves are designed and built to withstand extreme temperatures and pressures. Customization options also allow for the adaptation of these valves to specific environmental conditions, making them ideal for a multitude of applications in harsh industrial settings.

Rexroth Servo Valves continue to be at the forefront of industrial innovation, delivering unmatched precision and reliability. For those in fields requiring meticulous fluid dynamics, understanding and effectively utilizing these valves can result in significant operational enhancements. As technology progresses, the continuous development of servo valve technology promises even greater capabilities, enhancing control, efficiency, and adaptability across diverse industrial applications.

Looking ahead, the future development of Rexroth Servo Valves is likely to take place along several key trajectories that align with technological advancements and industry needs. One significant trend is the integration of smart technology into valve systems. With the rise of the Internet of Things (IoT) in industrial automation, smart valves equipped with communication modules could offer real-time data exchange and remote monitoring capabilities. This integration could help in preemptive maintenance strategies, allowing for rapid responses to potential issues and ultimately enhancing system uptime.

Furthermore, advancements in artificial intelligence (AI) and machine learning can lead to improved algorithms for automated adjustment, maximizing system performance based on predictive analytics. Such innovations could transform how industries approach operational efficiency and preventative maintenance. For example, an AI-enhanced Rexroth Servo Valve could analyze historical performance data to adaptively modify its operation, optimizing both energy consumption and fluid dynamics on-the-fly.

Moreover, advancements in materials science could lead to the development of even more durable and resilient valves capable of handling extreme pressures and temperatures, thereby broadening the range of applications. As industries demand more sustainable solutions, Rexroth may also focus on designing valves that enhance energy efficiency even further, thus supporting the global push for greener manufacturing practices.

In conclusion, Rexroth Servo Valves are not just components of hydraulic systems; they are facilitators of precision, efficiency, and adaptability in modern industrial settings. As industries evolve and technology advances, these valves are poised to lead the charge in facilitating improved operational outcomes across various sectors. Understanding their mechanisms, applications, benefits, and future potential enables engineers and system designers to harness the full power of hydraulic technology. As we aim for greater efficiency and sustainability in industrial processes, Rexroth Servo Valves will undoubtedly remain key players in shaping the future of automation and fluid control solutions.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!