This article delves into the intricacies of Rexroth Servo Valves, essential components in precise motion control applications. Known for their durability and accuracy, these servo valves are integral to various industries including automotive, aerospace, and manufacturing. The content explores their function, design, and advantages, offering insights for both current users and potential adopters.

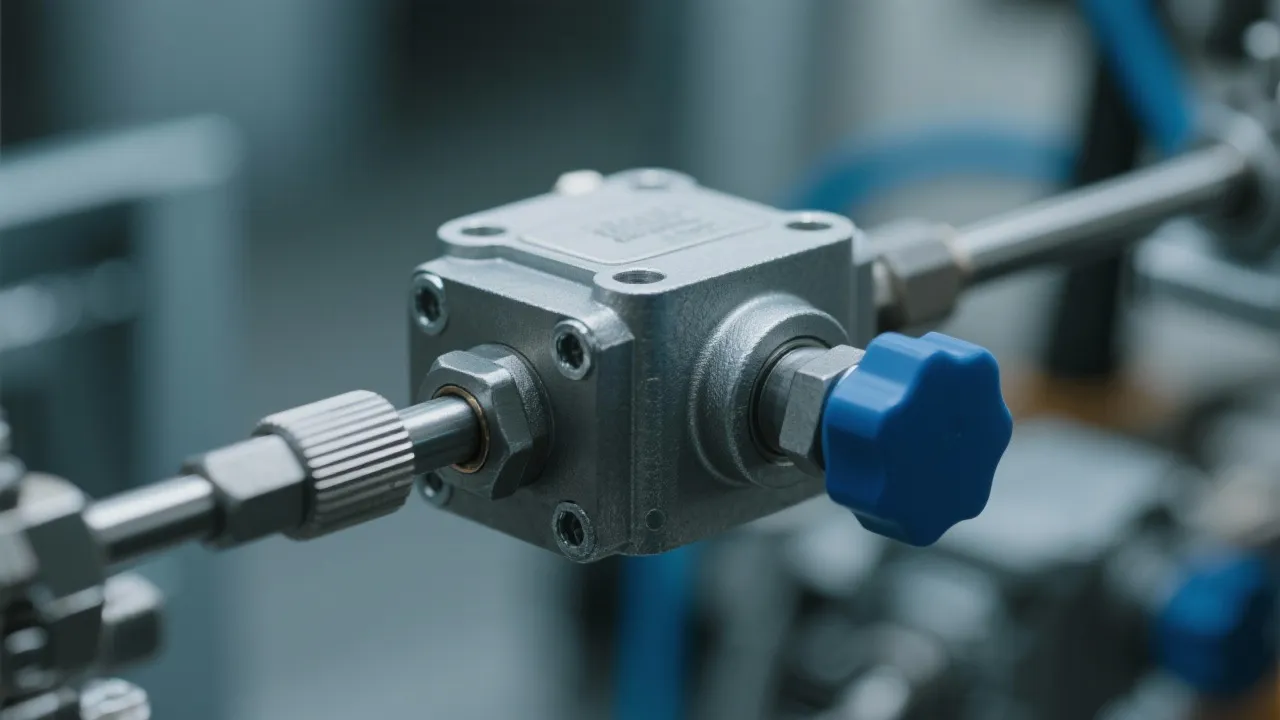

Rexroth Servo Valves are crucial components in the landscape of precision motion control, highly valued for their remarkable ability to regulate fluid flow in hydraulic systems with incredible accuracy and efficiency. Designed by Bosch Rexroth, a leader in drive and control technologies, these valves are employed widely across various sectors such as aerospace, automotive, and manufacturing, serving as integral parts in machines requiring precise positioning and force control. The significance of Rexroth Servo Valves extends beyond mere function; they symbolize a sustained commitment to innovation and excellence in engineering that meets the evolving demands of complex industrial processes.

The primary role of a servo valve is to convert an electronic input signal into a proportional hydraulic output that effectively controls motion and position. This transformation is achieved through intricate designs that include electromechanical components, ensuring that the desired output matches the input with minimal variance. The precision offered by these valves makes them indispensable in applications involving robotics, CNC machinery, and automated assembly lines. As a result, industries leverage these valves for tasks demanding extreme precision and reliability, such as in aerospace applications where the slightest deviation can lead to catastrophic failures or in medical devices requiring highly accurate movement to ensure patient safety.

Rexroth Servo Valves exemplify innovation through their compact and robust design, which accommodates various operational requirements. The incorporation of advanced materials and manufacturing techniques enhances performance, extends longevity, and reduces maintenance needs. For instance, the use of hardened steel and advanced polymers contributes to the valves’ high wear resistance, making them suitable for high-demand environments. Their adaptability to digital interfacing further cements their relevance in modern automated systems, offering seamless integration with cutting-edge industrial controls. As automation becomes increasingly prevalent, the requirement for valves that can rapidly communicate with control systems in real-time becomes paramount. Rexroth has responded to this demand by ensuring that their servo valves can interface with a variety of digital protocols, thus enhancing their versatility and application scope.

| Feature | Rexroth Standard Model | Competitor Model |

|---|---|---|

| Accuracy | ±0.1% Full Scale | ±0.2% Full Scale |

| Durability | High Wear Resistance | Moderate Wear Resistance |

| Integration | Seamless with Digital Systems | Analog Preferred |

| Response Time | Fast Response (< 1 ms) | Standard Response (2-5 ms) |

| Power Consumption | Low Power Consumption | Higher Power Draw |

These valves offer several advantages that directly contribute to system performance, including enhanced efficiency, noise reduction, and consistent performance under demanding conditions. The high degree of precision provided by Rexroth Servo Valves enables manufacturers to achieve tighter tolerances, which leads to better product quality and reduced waste. Their programmable nature allows for real-time adjustments, minimizing downtime and boosting productivity significantly, especially in applications requiring frequent changes in operational parameters. Furthermore, their construction ensures fewer leaks and reduced operational costs, contributing to overall savings for enterprises. These advantages help in building a more sustainable operation, aligning with modern industry trends towards minimizing environmental impact while maximizing output.

A thorough understanding of servo valves, like those offered by Rexroth, reveals an ongoing trend toward increasing automation and precision in various industries. The rise of Industry 4.0 has shifted the focus towards interconnected systems that rely heavily on smart components capable of making instantaneous decisions. Experts agree that the continued evolution of these components will lead to smarter systems capable of handling complex tasks autonomously. Innovations such as IoT integration in process controls allow for data-driven optimizations in real time. For businesses aiming to maintain a competitive advantage, investing in technology that offers high precision and reliability is crucial. It’s essential to not only consider the initial cost of these servo valves but also their long-term operational benefits—ranging from increased throughput to decreased fault rates in production lines.

The deployment of Rexroth Servo Valves represents a strategic enhancement for any enterprise seeking precision, reliability, and cost-effectiveness in its hydraulic control processes. As industries continue to evolve towards more sophisticated applications, the role of high-performance components like these servo valves will grow ever more critical, ensuring their relevance and demand in the future landscape of industrial automation. Investing in advanced technologies such as Rexroth Servo Valves not only supports operational excellence but also aligns with the broader goals of efficiency and sustainability that modern businesses strive to achieve.

To fully appreciate the capabilities of Rexroth Servo Valves, it is essential to examine their technical specifications closely. These specifications provide detailed insights into performance characteristics, limitations, and suitability for various applications. Typical features include:

To ensure the longevity and optimal performance of Rexroth Servo Valves, a robust maintenance regimen is necessary. Here are some best practices that technicians and operators can adopt:

A closer look at practical applications of Rexroth Servo Valves can yield valuable insights. Various industries have reported improvements in efficiency, reliability, and overall system performance. For example:

Looking ahead, the importance of Rexroth Servo Valves will only continue to grow as the push for automation and smart manufacturing accelerates. As industries embrace digital transformation and the integration of IoT technologies, the demand for precise motion control systems characterized by speed, accuracy, and reliability will significantly rise. Rexroth’s commitment to research and development positions it well to lead in this evolving field, ensuring their products remain front and center in discussions of advanced fluid power solutions and automation strategies.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!