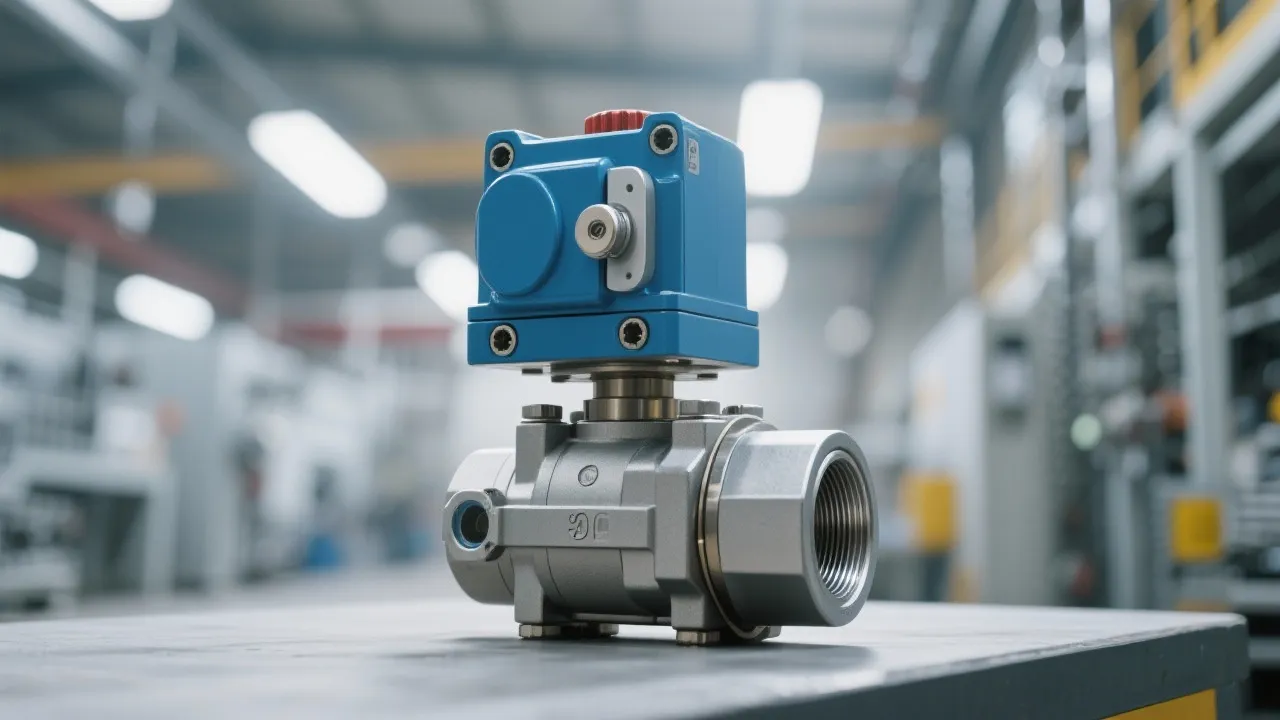

This comprehensive guide delves into the intricacies of Rexroth Servo Valves, highlighting their critical role in modern automation. Rexroth, a renowned leader in motion control solutions, emphasizes precision with its servo valves, vital for engineering sectors. This article explores how these valves optimize performance by adjusting pressure or fluid flow, essential for machinery across industries.

In the dynamic field of automation and motion control, Rexroth Servo Valves stand out as pivotal components engineered to enhance precision and efficiency. Known for their robust design and reliability, these valves are indispensable in applications requiring exact control over hydraulic fluid movement. From manufacturing to aerospace, Rexroth Servo Valves improve system responsiveness and accuracy, making them a preferred choice among industry professionals. Their unique design optimizes hydraulic performance, leading to better overall system functionality.

Rexroth, a part of the Bosch Group, leverages cutting-edge technology to design servo valves that ensure optimal fluid dynamics. By precisely controlling the flow rate and direction, these servo valves play a crucial role in machine accuracy and performance. Hydraulic systems, for instance, rely on these valves for tasks such as adjusting actuator movement or maintaining specific pressures. The technology behind Rexroth Servo Valves incorporates various engineering principles, such as fluid mechanics and control theory, to achieve the desired functionality. This includes electronic control of valve operations, allowing for faster response times and greater precision in hydraulic actuation.

Automation systems require components that offer consistent and reliable performance under varying conditions. Rexroth Servo Valves meet these demands with exceptional precision, providing fine-tuned control over hydraulic systems used in diverse applications, including manufacturing, automotive production, and heavy machinery operations. The integration of these valves supports improved system efficiency and reduces downtime, essential for operational continuity. In a world where quick adjustments are necessary, these valves allow for the agile handling of different tasks, making them ideal for modern industrial environments.

A servo valve is an electro-hydraulic component used to control fluid flow precisely and dynamically, often in automated systems. The valve enables proportional control of hydraulic actuators by varying the hydraulic flow based on electronic input signals.

Rexroth Servo Valves are favored due to their precision, durability, and adaptability to a range of industrial applications. Their reliable performance in critical operations in sectors like aerospace and automotive has built a strong reputation in the market.

They are available through authorized distributors and suppliers who specialize in Bosch Rexroth products. It's always advisable to get them from verified sources to ensure product authenticity and support.

Routine maintenance includes checking for fluid contamination, verifying electrical connections, and ensuring that seals are intact. Regular servicing helps sustain the valves' performance and prevent any unexpected failures.

Compared to traditional valves, Rexroth Servo Valves offer superior precision and responsiveness due to their electronic control mechanisms. They can respond to control inputs much quicker and adjust the flow more finely, which is crucial for modern automation systems.

The integration of Rexroth Servo Valves into hydraulic systems translates into enhanced operational efficiency and accuracy. Industries depending on precise load control—such as plastic processing and metal forming—benefit significantly from the high responsiveness and minimal lag time of these valves. Moreover, in applications ranging from semiconductor manufacturing to robotics, the ability to finely tune the fluid dynamics allows for delicate manipulation and positioning of equipment. This capability is increasingly critical in high-tech industries where precision is paramount.

| Feature | Rexroth Servo Valve | Other Servo Valves |

|---|---|---|

| Precision | High | Moderate |

| Durability | Robust under extreme conditions | Varies by manufacturer |

| Energy Efficiency | Optimized for low consumption | Standard |

| Versatility | Applicable across multiple industries | Industry-specific |

| Feedback Mechanism | Advanced closed-loop feedback systems | Basic or no feedback options |

| Operation Response Time | Rapid and responsive | Slower in comparison |

The utilization of Rexroth Servo Valves brings several significant advantages. First and foremost is their capability to provide exceptional control over hydraulic flow, which is essential for high-performance machinery. This control results in smoother operation and minimizes mechanical stress, thereby extending the lifespan of actuators and related components. Additionally, the energy efficiency of these valves reduces operating costs by lowering power consumption.

Another notable advantage lies in their adaptability. Rexroth Servo Valves can be integrated into existing systems with minimal modification, allowing for quick upgrades to enhance performance without overhauling the entire system. This flexibility is particularly appealing to companies looking to modernize their operations without incurring significant downtime or expense.

Rexroth Servo Valves find applications across various sectors, highlighting their versatility and importance in industrial automation. Some key applications include:

The landscape of servo valve technology is continually evolving, influenced by advancements in both materials and electronics. One of the notable trends is the integration of IoT (Internet of Things) capabilities, allowing for real-time monitoring and predictive maintenance of valve systems. This connectivity will enable operators to gather data on valve performance and make proactive decisions to enhance system uptime.

Furthermore, miniaturization is becoming increasingly significant, particularly in applications requiring compact designs without sacrificing performance. Engineers are working on smaller, more efficient servo valves that can control fluid movement with the same precision as larger counterparts, effectively reducing space requirements in machinery.

Another trend is the focus on sustainability and energy conservation. Manufacturers, including Rexroth, are pursuing designs that minimize fluid loss and energy consumption while maximizing flow efficiency. This emphasis not only reduces operating costs but also aligns with global efforts towards environmental responsibility.

In sum, Rexroth Servo Valves represent the pinnacle of hydraulic control technology, providing unmatched precision and reliability to modern automation systems. Their implementation not only elevates operational capabilities across numerous fields but also ensures sustainable and efficient workflows. For industries aiming to optimize performance and reduce operational costs, these servo valves present an invaluable engineering solution. As technology continues to advance, the capabilities and applications of Rexroth Servo Valves are poised for even greater growth, solidifying their role as key components in the future of automated systems.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!