Rexroth Servo Valves are critical components in hydraulic systems, offering precision control and high performance for industrial applications. These valves, known for their reliability and efficiency, are integral in sectors ranging from manufacturing to aerospace. Understanding their function and impact is essential for optimizing machinery operations and improving technological efficiency.

Rexroth Servo Valves are pivotal in modern hydraulic systems, known for their precision and reliability. As one of the leading solutions in fluid power technology, these valves are essential for converting electrical signals into precise fluid output in hydraulic machinery. They are widely used across various sectors, including aerospace, automotive manufacturing, and industrial automation, due to their robust design and efficiency. Innovations in design and performance have made Rexroth Servo Valves an integral part of both existing and emerging technologies, ensuring that they continue to meet the demanding needs of advanced industries.

At the core, Rexroth Servo Valves serve as a critical interface between electronic control systems and mechanical outputs. They efficiently control hydraulic fluid flow to actuators based on electrical input, allowing for accurate positioning, speed, and force controls in various applications. This precise handling ensures optimal performance and safety in operational settings, reducing downtime and maintenance costs. The valves operate by modulating the flow and pressure of hydraulic fluid through their specially designed pathways, ensuring that actuators perform their tasks with the utmost accuracy.

Furthermore, the design of Rexroth Servo Valves allows for scalability and adaptability. As industries evolve and the demands for precision increase, these valves can be adapted to accommodate new technologies, including advanced control strategies and predictive maintenance systems. By using these valves, operators can integrate sophisticated monitoring equipment and smart sensors into their hydraulic systems, providing real-time data and feedback on system performance.

The versatility of Rexroth Servo Valves makes them a preferred choice in a broad range of industrial applications. In the aerospace industry, they are used for flight control systems, where precision is paramount. The ability to finely tune the control of flight surfaces leads to improved aircraft performance and safety. Automotive manufacturing employs these valves for advanced vehicle testing systems and assembly lines, where they facilitate precise movements and positioning in robotic assembly systems.

Moreover, in the field of robotics, Rexroth Servo Valves are critical in providing motion control that is exact and responsive. Whether it's in robotic arms used for delicate assembly tasks or in automated guided vehicles (AGVs) that require smooth acceleration and deceleration, the reliability and precision of these valves contribute significantly to overall operational efficiency. Furthermore, they are increasingly used in renewable energy applications, where they assist in controlling the hydraulic systems in wind turbines and solar tracking systems, optimizing energy production and system longevity. The automotive industry benefits from integrating these valves in testing rigs to validate performance under various load conditions.

The expansion of smart factories and Industry 4.0 technologies has also seen an uptick in the use of Rexroth Servo Valves. Integration of IoT devices enables remote monitoring and control of hydraulic systems, leading to enhanced operational monitoring. This capability allows managers to analyze performance metrics and perform predictive maintenance, which decreases unexpected failures and maintenance costs.

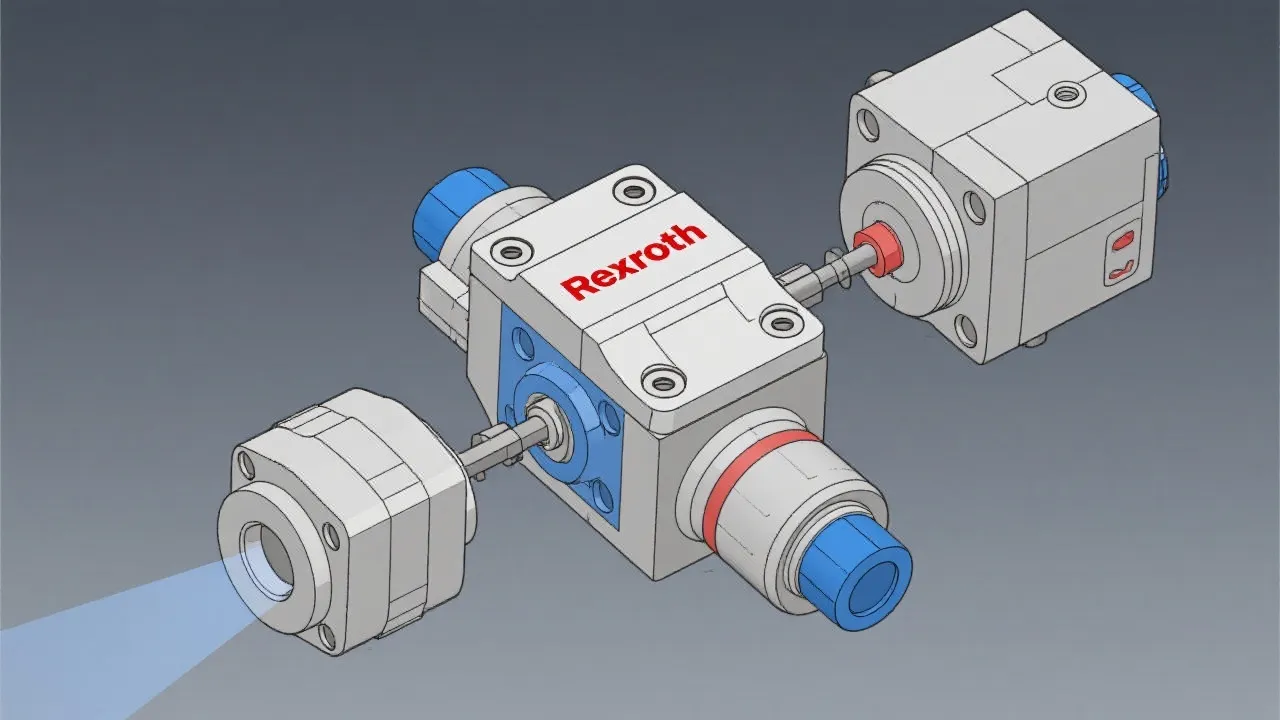

Understanding the technical aspects of Rexroth Servo Valves involves a deep dive into their components and operational mechanics. These valves operate on a closed-loop system that includes a hydraulic spool, torque motor, and feedback mechanisms. The torque motor converts electronic signals into mechanical motion, moving the spool to direct hydraulic fluid with precision. Feedback systems ensure that the valve maintains the desired position, optimizing performance and stability. This direct relationship between electronic input and hydraulic output is crucial for achieving the precision control required in many applications.

Additionally, the use of advanced materials and coatings enhances the performance capabilities of these valves. For instance, high-strength alloys can be used for the internal components, minimizing wear and prolonging service life, while specialized coatings can reduce friction and inhibit corrosion in harsh operating environments. The intricate design of the internal flow paths also aids in preventing turbulence, which contributes to smoother operation across a wider range of speeds and pressures.

The modular design of Rexroth Servo Valves allows for easy maintenance and repair, which is essential in high-availability systems. Users can replace specific components without needing to overhaul the entire system, saving both time and costs. Additionally, built-in diagnostic features empower operators to identify potential failures before they impact system performance, further enhancing reliability. Utilizing certain algorithms, these valves can also adapt to the changing operational requirements, providing a more dynamic response to varying workload conditions.

Rexroth Servo Valves incorporate several innovations, including linear control capabilities, high-frequency response, and integrated electronics for enhanced performance. These features contribute to improved accuracy and reliability in complex applications. Innovations such as closed-loop control systems allow for real-time adjustments based on feedback, which is crucial for maintaining optimal performance in dynamic environments. The integration of digital control technologies further amplifies their ability to facilitate seamless communication between machinery components, fostering smarter systems and superior operational output.

One noteworthy innovation in Rexroth Servo Valves is the ability to include multiple control strategies within the same unit. For example, adaptive control algorithms can be implemented to adjust the valve's response based on changing load conditions or operational requirements. This flexibility not only improves system responsiveness but also enhances energy efficiency, as the system can dynamically adjust its input to minimize waste while maximizing output.

Furthermore, advancements in connectivity, such as the use of Industry 4.0 standards, allow Rexroth Servo Valves to interface with broader manufacturing systems. This enables operators to derive data analytic insights from valve performance that can be used to refine operational strategies. The combination of precision control and smart technology incorporation positions Rexroth Servo Valves as a future-ready solution for evolving industrial challenges.

Rexroth Servo Valves are known for their advanced electronic integration, robust design, and high precision, making them stand out in performance and reliability. The ability to couple innovative feedback mechanisms with their smart technology puts them at the forefront of hydraulic solutions.

These valves are utilized in diverse industries such as aerospace, automotive, and industrial automation due to their precise control capabilities. Their adaptability makes them suitable for both high-speed and high-torque applications.

By providing precise control over hydraulic fluid movement, these valves ensure smooth and efficient operations, reducing system wear and downtime. Their ability to communicate with other system components leads to predictive insights that can be used for maintenance, ultimately extending the life of the hydraulic systems.

Regular inspections and diagnostics are recommended to ensure optimal performance. Many models come with self-diagnostic capabilities that can alert operators to potential issues before they escalate, ensuring timely maintenance.

Yes, they are designed to be compatible with many existing hydraulic systems, provided the appropriate specifications are followed. Systems may require some updates or additional hardware to maximize effectiveness.

Rexroth Servo Valves continue to lead in hydraulic technology due to their precision, reliability, and versatility. Their role in optimizing industrial operations emphasizes the importance of understanding and integrating advanced servo control systems into various applications. As industries evolve towards increased automation and efficiency, these valves stand as a cornerstone of innovative machinery and industrial processes. Such continuous advancement not only positions Rexroth at the forefront of hydraulic solutions but fosters a culture of innovation and excellence within the broader engineering community.

The ongoing development of Rexroth's technology is also relevant in discussions about sustainability in engineering. By improving energy efficiency and reducing waste in hydraulic systems, Rexroth Servo Valves contribute to broader environmental goals that many manufacturing companies are striving to achieve. The use of high-efficiency pumps in conjunction with these valves can further enhance system performance, aligning operational goals with sustainable practices.

In summary, as industries navigate through the complexity of modern demands, Rexroth Servo Valves offer a pathway to not only maintain but elevate operational capabilities. The integration of technology, adaptability, and precision makes them essential components in the pursuit of future-ready industrial solutions.

| Specification | Detail |

|---|---|

| Control Precision | High-precision control with feedback mechanisms. |

| Frequency Response | Up to several hundred Hz depending on model. |

| Integrated Electronics | Yes, facilitating advanced control and diagnostics. |

| Operating Pressure Range | Typically 60 to 350 bar, depending on specific model. |

| Fluid Compatibility | Multi-compatible, fluids ranging from hydraulic oils to water glycols. |

| Power Supply | DC voltage options—generally between 24 to 220 V depending on model. |

For industries seeking enhanced performance and reliability in hydraulic applications, Rexroth Servo Valves present a sophisticated solution, combining state-of-the-art technology and durable engineering. Their emphasis on precision, adaptability, and sustainability not only makes them fit for current applications but positions them as leaders in shaping the future of hydraulic systems.

In conclusion, the robust feature set and versatility of Rexroth Servo Valves empower industries to fine-tune their operations, enhance process efficiency, and maintain superior levels of productivity and safety. Their enduring presence in the market and continued innovations ensure that they remain a preferred choice among engineers and operators globally.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!