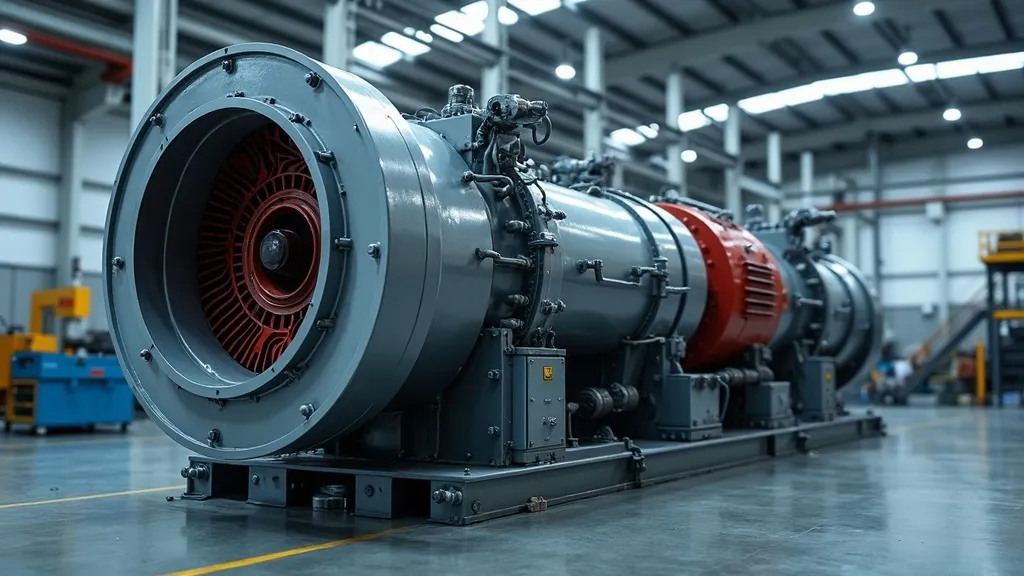

Regenerative blowers are essential in various industries for moving air and gases efficiently. These devices operate by utilizing non-positive displacement to create a constant flow of air or gas. Unlike traditional fans or compressors, regenerative blowers are valued for their ability to deliver high volumes at relatively low pressures, making them ideal for applications requiring continuous airflow.

Regenerative blowers, often referred to as side channel blowers, are critical components in many industrial applications. Known for their ability to move large volumes of air or gas at low pressure, these blowers are indispensable in settings that demand continuous airflow, such as wastewater treatment plants, pneumatic conveying systems, and aquaculture. Their design allows for efficient operation, making them a cost-effective solution for industries focused on energy conservation. In recent years, the demand for regenerative blowers has surged, driven by a greater emphasis on sustainability and energy efficiency across various sectors.

The operation of a regenerative blower is based on a non-positive displacement mechanism. Air or gas enters the blower through an inlet and is accelerated by an impeller. As the impeller rotates, it pushes the air or gas into a series of channels, where it is repeatedly accelerated and decelerated. This process creates a vortex, enhancing the pressure and velocity of the airflow before it exits through the outlet. This unique mechanism allows regenerative blowers to maintain a steady flow rate, even under varying load conditions. Additionally, the design of the impellers and the configuration of the channels are optimized to minimize turbulence and maximize efficiency, contributing further to the blower's performance.

Regenerative blowers find applications across a myriad of industries, thanks to their versatility and reliability. In wastewater treatment, they facilitate aeration, which is crucial for the breakdown of organic matter. The aeration process is essential in ensuring that bacteria can efficiently decompose waste, leading to cleaner water being discharged into the environment. In the plastics industry, they are used for vacuum hold-down systems and material conveying, critical for processes like thermoforming where precise material handling is necessary.

Furthermore, regenerative blowers play a vital role in the food and beverage sector by ensuring hygiene during packaging processes through the removal of moisture and debris. This is particularly important in maintaining food quality and extending shelf life. Their application extends to the medical device manufacturing sector, where controlled environments are essential for quality assurance and compliance with stringent health regulations. These blowers are also employed in the electronics industry for cooling and drying processes, showcasing their adaptability across various manufacturing settings.

Moreover, regenerative blowers are also utilized in HVAC systems for ventilation and air circulation, providing energy-efficient solutions for heating and cooling applications. Their ability to operate at low noise levels makes them an excellent choice for residential and commercial buildings alike, where occupant comfort is a priority. In the realm of aquaculture, they are instrumental in oxygenating water bodies, which is vital for fish health and growth, illustrating their significant role in sustainable aquaculture practices.

| Feature | Regenerative Blowers | Traditional Fans |

|---|---|---|

| Airflow | High volume, low pressure | Variable, depending on design |

| Noise Level | Low | Medium to high |

| Maintenance | Low | Moderate |

| Efficiency | High | Variable |

| Power Consumption | Lower than traditional fans for equivalent airflow | Higher, especially at higher pressures |

| Application Range | Wide range including specialized industrial applications | General ventilation and cooling |

What industries benefit most from regenerative blowers?

Industries such as wastewater treatment, pneumatic conveying, aquaculture, food and beverage processing, and medical device manufacturing greatly benefit from the efficiency and reliability of regenerative blowers. Their ability to provide consistent airflow at lower energy costs makes them particularly advantageous in sectors where operational efficiency is critical.

How do regenerative blowers differ from traditional compressors?

Regenerative blowers operate at lower pressures and are used for continuous airflow applications, unlike compressors which are typically used for higher pressure applications. Compressors are designed to compress air or gas to significantly higher pressures, making them suitable for applications such as pneumatic tools or industrial refrigeration systems. In contrast, regenerative blowers excel in applications requiring consistent airflow without the need for high pressure.

Are regenerative blowers energy efficient?

Yes, they are designed to offer high efficiency, using less energy to move large volumes of air, which translates to cost savings in energy consumption. Their operational design minimizes energy loss, making them an environmentally friendly choice for industries striving to reduce their carbon footprint.

What is the lifespan of a regenerative blower?

The lifespan of a regenerative blower can vary based on operating conditions and maintenance practices, but generally, they are designed for long-term use. With proper care and maintenance, they can last several years, often exceeding the lifespan of more traditional blower models. Regular inspections and adherence to manufacturer guidelines can significantly enhance their durability.

Can regenerative blowers handle corrosive gases?

While standard regenerative blowers are not typically designed to handle corrosive gases, there are specialized models available that are constructed with materials resistant to corrosion. It is crucial to consult with manufacturers to ensure that the right type of blower is selected for specific applications involving corrosive substances.

In conclusion, regenerative blowers are a vital component in modern industrial operations, providing reliable and efficient airflow solutions that enhance productivity and sustainability. Their diverse applications and advantages underscore their importance in various sectors, making them a preferred choice for businesses aiming to optimize their processes. As industries continue to seek out innovative and energy-efficient solutions, the role of regenerative blowers in facilitating these advancements will undoubtedly grow, solidifying their place in the future of industrial technology.

The landscape of regenerative blower technology is evolving rapidly, driven by advancements in engineering and a growing emphasis on sustainability. Manufacturers are increasingly focusing on creating blowers that not only perform effectively but also align with the principles of green manufacturing. This involves optimizing designs for energy efficiency, reducing noise levels, and utilizing materials that are environmentally friendly.

One significant trend is the integration of smart technology into blower systems. By incorporating sensors and IoT (Internet of Things) capabilities, regenerative blowers can be monitored and controlled remotely, allowing for real-time adjustments based on operational needs. This smart functionality can lead to further energy savings and improved operational efficiency, as systems can be fine-tuned for optimal performance.

Additionally, as industries shift towards automation and digitalization, regenerative blowers are expected to become integral components of automated systems, particularly in manufacturing processes where precision and reliability are crucial. The ability to integrate these blowers with other automated machinery will enhance production capabilities and streamline workflows, contributing to overall operational efficiency.

Another trend is the growing use of regenerative blowers in renewable energy applications. As the world moves towards sustainable energy sources, these blowers are being explored for use in biogas plants, wind energy systems, and other renewable energy technologies. Their efficiency and low environmental impact make them ideal candidates for supporting the transition to greener energy solutions.

Furthermore, the demand for customized blower solutions is on the rise. Industries are increasingly looking for blowers tailored to their specific operational requirements. This has prompted manufacturers to invest in research and development to create bespoke designs that meet unique industry needs, whether it's in terms of size, airflow capacity, or material specifications.

In summary, the future of regenerative blowers looks promising, marked by innovation, sustainability, and adaptability. As businesses continue to seek ways to improve efficiency and reduce environmental impact, regenerative blowers will play a crucial role in shaping the future of industrial airflow solutions.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!