Regenerative blowers are pivotal components in various industrial applications, known for their efficiency in moving large volumes of air at low pressures. This guide explores their functionalities, applications, and benefits, offering insight into why they are favored over traditional air-moving devices. Readers will gain a comprehensive understanding of how these blowers contribute to enhanced operational efficiency and energy savings across industries.

Regenerative blowers have become indispensable in numerous industrial applications, thanks to their ability to move large volumes of air at relatively low pressures. Unlike traditional centrifugal blowers, regenerative blowers use a non-positive displacement mechanism, which makes them highly efficient for specific tasks. This article explores the technology behind regenerative blowers, their applications, benefits, and how they stand out in the realm of industrial air movement solutions. The increasing demand for energy-efficient and low-maintenance equipment in various sectors has further propelled the adoption of these blowers, making them a critical component in modern industrial operations.

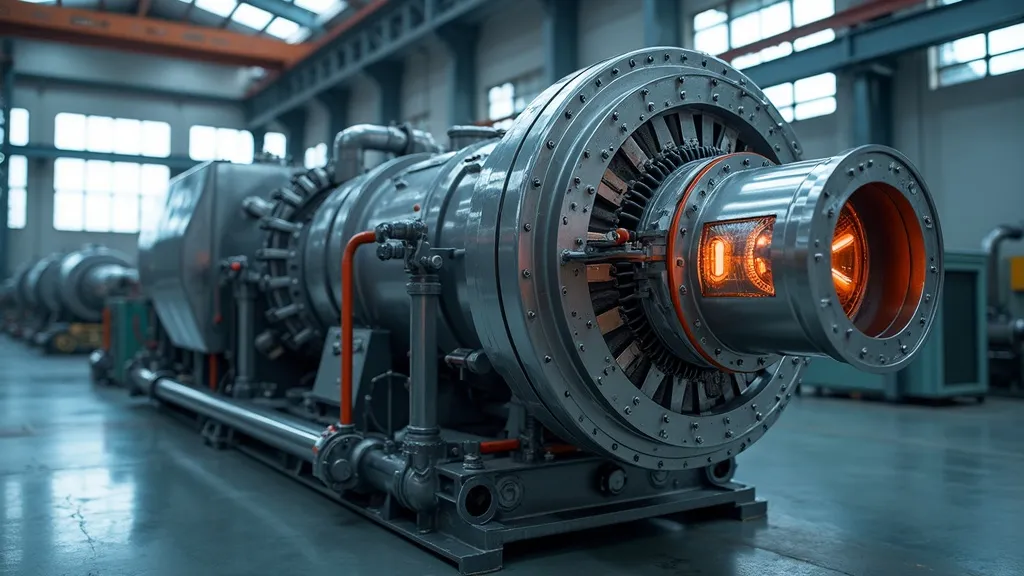

The operational principle of a regenerative blower is based on the use of an impeller, which rotates within a housing. As air enters the blower, it is accelerated by the impeller blades and directed into a peripheral channel. This creates a vortex, which regenerates the air pressure with each pass around the channel. The process repeats multiple times, allowing the blower to build up pressure incrementally, unlike single-stage compression systems found in other blowers. Each rotation of the impeller enhances the efficiency of air movement, and the design allows for continuous operation without significant wear on the components.

Moreover, the regenerative process inherent in the design means that air can be moved in both directions, allowing for both blowing and vacuuming capabilities. The versatility of regenerative blowers in this regard makes them suitable for various applications, from aeration in wastewater treatment to vacuum lifting in manufacturing processes. The ability to switch between these functions without the need for extensive modification is a testament to their engineering efficiency.

Regenerative blowers are versatile and find applications across a broad spectrum of industries. They are commonly used in wastewater treatment plants for aeration, in pneumatic conveying systems, and in vacuum operations such as packaging and lifting. In wastewater treatment, regenerative blowers supply the necessary air to promote aerobic bacteria growth, which is essential for breaking down organic matter. This application highlights their role in environmental sustainability and pollution control.

In the packaging industry, regenerative blowers are employed for vacuum sealing, where the removal of air from packaging helps in extending the shelf life of products. Additionally, in the material handling and transportation sectors, these blowers facilitate the movement of bulk materials through pneumatic conveying systems. This method of transport minimizes dust and contamination, making it a preferred choice in food processing and pharmaceutical manufacturing.

Furthermore, regenerative blowers are used in various HVAC systems to enhance air circulation and maintain air quality in commercial buildings. Their quiet operation makes them ideal for environments where noise pollution must be minimized, such as hospitals and schools. As industries continue to evolve and seek more efficient solutions, the applications for regenerative blowers are expected to expand, cementing their role in modern industrial practices.

One of the primary benefits of regenerative blowers is their efficiency. They are designed to handle large volumes of air with minimal energy consumption, contributing to significant operational cost savings. The design allows for a high volume of airflow with relatively low horsepower requirements, making them an economical choice for many applications. Moreover, because they are oil-free, they provide clean air, making them suitable for applications where air purity is essential, such as in food processing and pharmaceuticals.

Regenerative blowers also boast a compact design that allows them to fit in tight spaces without compromising performance. This is particularly beneficial in industries where space is at a premium. Their quiet operation adds to their appeal, especially in settings where noise is a concern, reducing the need for additional soundproofing measures.

Additionally, the durability of regenerative blowers is noteworthy. With fewer moving parts compared to other types of blowers, such as roots blowers, they experience less wear and tear, leading to a longer lifespan. This reliability translates into lower maintenance costs and reduced downtime, ultimately enhancing productivity. Their ability to operate continuously without the need for constant monitoring or adjustment makes them a reliable choice for critical processes.

| Type | Advantages | Disadvantages |

|---|---|---|

| Regenerative Blowers | Efficient, oil-free, quiet, compact | Limited to low-pressure applications |

| Centrifugal Blowers | High-pressure capability, versatile | Higher energy consumption, larger footprint |

| Roots Blowers | Robust, handles high pressure | Noisy, requires regular maintenance |

In the comparison above, regenerative blowers stand out primarily for their efficiency and lower operational costs. While centrifugal and roots blowers are better suited for high-pressure applications, they often come with trade-offs in terms of energy consumption and maintenance requirements. For applications where low to moderate pressure is sufficient, regenerative blowers provide a compelling alternative.

When selecting a regenerative blower, it is essential to consider the specific requirements of your application. Factors such as the volume of air needed, pressure requirements, and environmental conditions should guide your decision. It is also advisable to consult with suppliers who can offer personalized advice based on your operational needs. A thorough assessment of your system's requirements will ensure optimal performance and efficiency.

Another critical consideration is the blower's operating environment. For instance, if the blower will be used in a cleanroom or sterile environment, selecting a model that meets specific cleanliness standards is crucial. Additionally, examining the blower's sound levels can be important for applications in noise-sensitive environments.

Furthermore, understanding the required airflow rate and pressure can aid in the selection process. Regenerative blowers are rated according to their flow capacity and pressure output, so reviewing these specifications against your system’s requirements will help ensure that you select the right model.

Q: What maintenance do regenerative blowers require?

A: Regenerative blowers are designed for low maintenance. Regular checks for debris and ensuring the impeller is free of obstructions are usually sufficient. It is also advisable to periodically inspect the blower's housing and connections for any signs of wear or damage to ensure continued efficiency and performance.

Q: Are regenerative blowers suitable for high-pressure applications?

A: No, regenerative blowers are typically suited for low-pressure applications. For high-pressure needs, other types of blowers such as centrifugal or roots blowers are recommended. Understanding the limitations of regenerative blowers is crucial for ensuring that the right equipment is used for specific applications.

Q: Can regenerative blowers be used in explosive environments?

A: While some regenerative blowers are designed for use in specific hazardous environments, it is crucial to check the specifications and certifications of the blower for such applications. Compliance with safety standards and regulations is essential to prevent potential hazards in explosive environments.

Q: What factors affect the lifespan of regenerative blowers?

A: The lifespan of regenerative blowers can be influenced by several factors, including the frequency of use, operating conditions, and maintenance practices. Regular maintenance, such as cleaning and lubrication, can extend the life of the blower. Additionally, ensuring the blower operates within its specified parameters will help prevent premature failure.

Q: How do I troubleshoot performance issues with my regenerative blower?

A: Performance issues can often be traced back to blockages in the air intake or exhaust, improper installation, or wear on the impeller. Regular inspections can help identify and resolve these issues before they impact performance. If problems persist, consulting with a technical expert or the manufacturer may be necessary for more in-depth troubleshooting.

Regenerative blowers are a critical component in modern industrial operations, offering an efficient, reliable, and low-maintenance solution for air movement. Whether you are involved in wastewater treatment, material handling, or any other application that requires continuous airflow, understanding the capabilities and benefits of regenerative blowers can lead to improved operational efficiency and energy savings. Always ensure you choose the right type of blower for your specific needs to maximize performance and longevity.

As industries continue to evolve and adapt to new standards of efficiency and sustainability, regenerative blowers are likely to play an even more significant role. Their unique advantages make them a preferred choice in an array of applications, and ongoing advancements in technology will only enhance their capabilities and performance. By staying informed about the latest developments and best practices in blower technology, businesses can better position themselves to leverage these systems for optimal results.

In conclusion, regenerative blowers not only contribute to operational efficiency but also support environmental sustainability efforts across various industries. By minimizing energy consumption and reducing maintenance requirements, they help organizations achieve their operational goals while adhering to sustainability standards. As we look to the future, the role of regenerative blowers in industry is set to grow, making it essential for businesses to understand their potential and applications.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!