This comprehensive guide delves into the intricate world of proportional valves, crucial components in various industrial applications. Proportional valves are essential for precise fluid control, offering improved system efficiency and responsiveness. Their significance in sectors such as manufacturing and automation is underpinned by their ability to manage fluid flow and pressure with accuracy.

In the vast realm of industrial automation, the role of a Proportional Valve cannot be overstated. These precise instruments are integral in regulating the flow and pressure of fluids—gases or liquids—within a myriad of systems. Their functionality is pivotal in ensuring consistent performance and enhancing the efficiency of numerous applications, including manufacturing, automotive, and aerospace sectors. As industries become increasingly sophisticated, the demand for these valves continues to rise, given their capacity for fine-tuned control and their adaptability across various settings.

Proportional valves function not merely as components but as critical drivers for innovation, enabling the development of advanced automation processes. The various benefits they bring to fluid control systems underscore their importance in modern industrial settings, where precision, reliability, and efficiency are paramount. To truly appreciate the advantages of proportional valves and how they operate, it is crucial to delve deeper into their mechanisms, applications, and the specific technologies that enable their functionality.

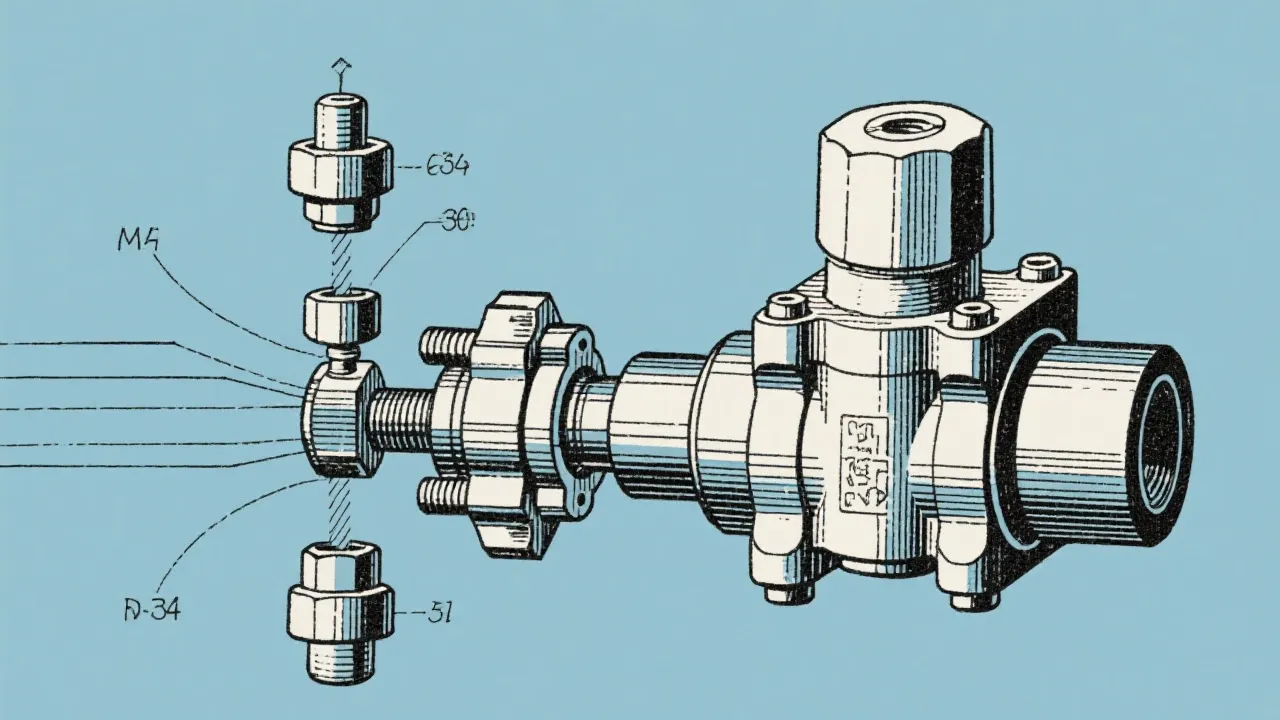

The primary mechanism of a proportional valve hinges on its ability to adjust the flow dynamically. Unlike traditional on/off valves, proportional valves provide a range of control, offering users the ability to fine-tune flow rates according to specific process requirements. This is achieved through the modulation of valve openings, governed by electrical signals that correspond to the desired flow rate. This mechanism is primarily facilitated through the following components:

This intricate interplay between the mechanical and electronic components makes proportional valves highly effective for various applications. By modulating flow rates with precision, industries can achieve optimal performance levels, minimize waste, and enhance overall system reliability.

Modern industries demand precision and efficiency in their processes, and proportional valves deliver just that. By enabling seamless control over fluid dynamics, these valves help industries reduce waste, optimize production timelines, and ensure product quality. They are especially prevalent in systems where stability, pressure control, and flow diversities are critical, such as in the hydraulic circuits of heavy machinery, automotive braking systems, and precise dosing systems in the food and beverage industries. The following applications exemplify the wide-ranging significance of proportional valves:

As industries evolve, the incorporation of proportional valves into new applications continues to demonstrate their versatility and importance across a wide array of sectors.

Several advantages make proportional valves an appealing choice for engineers and facility managers:

When considering the implementation of proportional valves in any application, it is essential to understand their core specifications and features. Table 1 provides an overview of critical technical specifications that affect the selection and performance of proportional valves:

| Specification | Detail |

|---|---|

| Operating Pressure | Varies depending on application; generally designed to withstand pressures ranging from 0 to 350 bar. Special designs can handle pressures above 350 bar for high-performance applications. |

| Flow Rate | Can range from a few liters per minute to several hundred, tailored to specific usage requirements. Each valve will have an optimal flow range, which must be respected to ensure efficiency and longevity. |

| Electronics | Includes integral amplifiers or external control modules for managing input signals. Some valves may even support digital communication protocols for enhanced compatibility with modern control systems. |

| Material | Often constructed from stainless steel or high-grade aluminum alloys which provide durability and resistance to corrosion and wear, ensuring that valves remain functional in challenging environments. |

| Response Time | Defines how quickly a valve can react to control signals, generally ranging between 10 ms to 100 ms, depending on the design and application needs. |

To select the very suitable proportional valve for an application, several factors must be considered:

Unlike standard valves, which operate on a binary open/close principle, proportional valves provide variable valve positions, allowing for continuous control over flow and pressure. This capability is critical for processes requiring delicate balance and where precision greatly affects outcomes.

While they are versatile, it's crucial to match the valve's specifications with the system's requirements, particularly regarding pressure and flow compatibility. Specific applications may have constraints based on the nature of the fluid, such as temperature or chemical composition, which need to be evaluated during selection.

Though upfront costs can be higher than traditional valves, the efficiency and longevity typically result in lower operational costs over time. Proper evaluation of total cost of ownership is essential when determining the economic viability of a valve over its lifecycle, including maintenance and energy savings.

Proportional valves are indispensable tools in the modern industrial landscape. Their capacity to accurately manipulate fluid flow and pressure is essential for sophisticated automation systems. As industries continue to evolve, the demand for such precision instruments will only grow, ensuring consistent development and innovation in this field.

Looking forward, the integration of smart technologies with proportional valves is on the horizon, allowing for enhanced monitoring and control. Innovations such as IoT-enabled valves are expected to revolutionize the way fluid control is managed, offering real-time data analytics and remote management capabilities. The future of proportional valves promises to deliver even greater efficiencies, opening up new avenues for industrial applications and pushing the boundaries of automation and control.

In summary, the significant role of proportional valves in enhancing operational efficiency, assuring quality, and promoting sustainable practices cannot be overlooked. As experts in fluid dynamics and automation seek solutions for increasingly complex challenges, proportional valves will undoubtedly play a pivotal role in shaping the future of industrial processes.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!