This article explores Lvdt Proportional Valves, integral components in modern industrial applications, functioning to control hydraulic systems with precision. These valves, known for their reliability and accuracy, are pivotal in industries that demand exacting control measures such as manufacturing and automation. The guide delves into their mechanics, lingering benefits, and frequent applications, helping decipher their importance in contemporary engineering solutions.

LVDT Proportional Valves play a crucial role in precision control within various industrial setups. They are instrumental in managing pressure and flow in hydraulic systems, providing the fine-tuned responsiveness necessary for operations requiring meticulous control. Understanding these valves is essential for engineers and technicians working in sectors ranging from manufacturing to robotics.

These valves utilize advanced technologies to ensure optimal performance, demonstrating how far engineering innovation has come in the pursuit of enhanced control systems. Their ability to work seamlessly with electronic controls and offer rapid adjustments make them a centerpiece of modern automated systems.

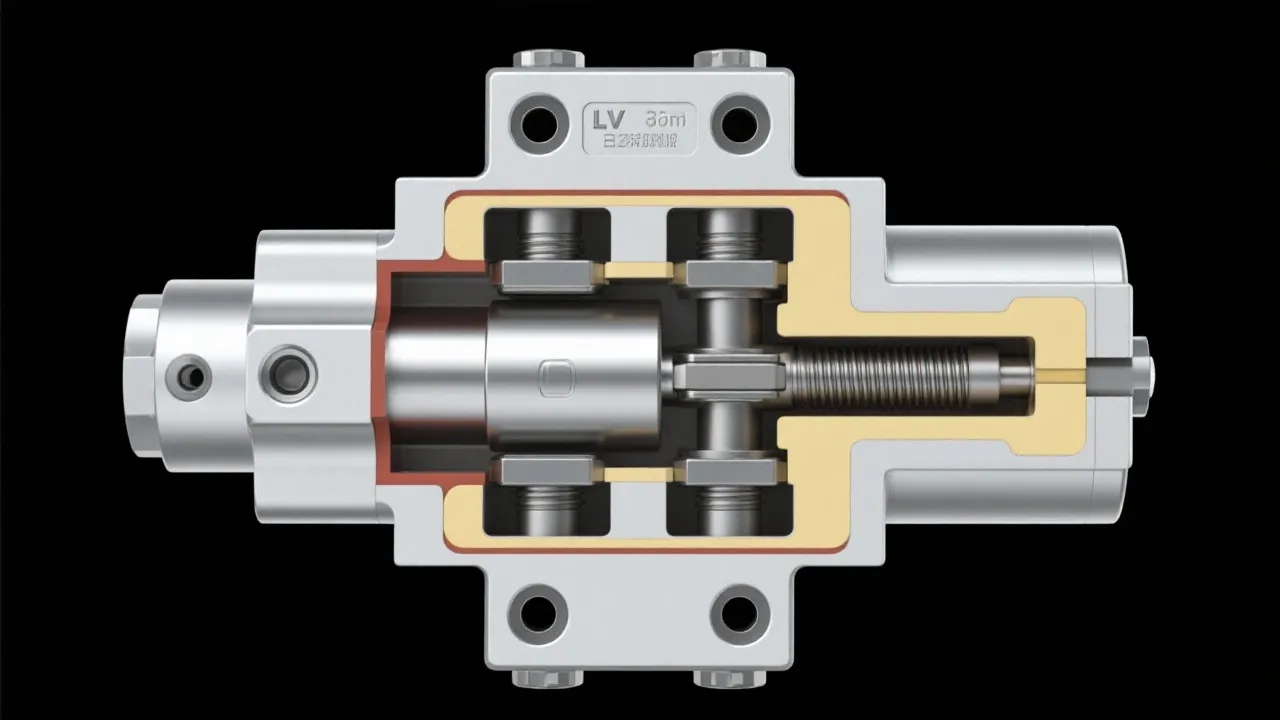

The core of LVDT Proportional Valves lies in their ability to provide linear displacement and variable control. The Linear Variable Differential Transformer (LVDT) embedded within these valves ensures precise movement, which is vital for tasks needing detailed positioning. This functionality makes them indispensable in environments where reliability and precision are of utmost importance.

The unique nature of these valves also stems from their hybrid functionality that combines the mechanical robustness of traditional hydraulic systems with the smart, responsive features of digital technologies. They stand out because they convert mechanical inputs into electrical signals, ensuring that adjustments to the flow or pressure do not disrupt the system's performance. The result is a seamless, reliable control mechanism that enhances operational efficiency across various industrial applications.

Moreover, LVDT Proportional Valves often come with feedback mechanisms that allow for continuous monitoring and adjustment, ensuring the system reacts based on real-time data inputs. This capability means that any sudden fluctuations in demand can be rapidly met, safeguarding not just equipment but also the overall integrity of the operations involved.

The operation of LVDT Proportional Valves hinges on electromagnetism. They use a coil assembly and a ferromagnetic core to detect positions, generating an output signal that controls the electrical circuit governing the valve's position. This setup facilitates real-time adjustments and feedback, which are crucial in maintaining system stability and responsiveness.

It is essential to understand how the LVDT mechanism operates: when the ferromagnetic core moves within the coil assembly, it alters the magnetic field, leading to a precise voltage output that correlates directly to the position of the core. The control electronics interpret these signals and adjust the valve opening accordingly to maintain the desired flow or pressure levels.

Due to their electromechanical integration, these valves have become a pivotal element in automation, providing the accuracy needed in sensitive applications such as aerospace, automotive, robotics, and heavy machinery. The adaptability of LVDT Proportional Valves allows them to be influential across multiple applications including lifting systems, material handling equipment, and adaptive manufacturing processes where responsiveness and precision are vital.

The deployment of LVDT Proportional Valves in industry brings numerous benefits:

The versatility of LVDT Proportional Valves translates into wide-ranging applications:

In manufacturing, they provide the precision needed for automated assembly lines, ensuring parts are moved and placed accurately. Their application extends from simple tasks such as opening and closing valves to complex systems that require nuanced positional control, such as robotic arms performing delicate assembly operations.

In aerospace, they are crucial for actuation systems where precision is paramount. LVDT Proportional Valves can adjust the airflow in cockpit controls or manage engine component positions, enhancing both safety and performance in flight. Moreover, their reliability in extreme conditions makes them suitable for high-stakes environments where system failures are intolerable.

In the automotive industry, LVDT Proportional Valves contribute to innovations in vehicular control systems, enhancing both performance and safety. For instance, they play a vital role in modern suspension systems, where they continuously adjust the resistance of dampers based on road conditions, providing drivers with an enhanced ride experience.

Another significant application is found in hydraulic machinery, where these valves control the operation of hydraulic actuators with exceptional accuracy. They play a fundamental role in equipment such as excavators, agricultural machinery, and lifting devices, allowing for the precise control required for varied, often heavy-duty tasks.

When purchasing LVDT Proportional Valves, consider the following factors to ensure you choose the right component for your application:

| Factor | Consideration |

|---|---|

| Specification | Select valves that match your system's pressure and flow requirements. Consult technical data sheets and specifications carefully to ensure compatibility. |

| Compatibility | Ensure the valve's compatibility with existing system components, including electrical connections and mounting solutions. |

| Supplier Reputation | Choose reputable suppliers known for their quality and reliability. Reading reviews and customer feedback can provide additional confidence in your choice. |

| Price | Evaluate the cost-effectiveness in relation to the valve's lifespan and performance. Avoid over-budget or underperforming solutions that could lead to higher overall costs in maintenance and operation. |

As industries continue to evolve and adopt more automation technologies, the development of LVDT Proportional Valves is expected to progress significantly. One of the promising trends is the integration of smart technologies, enabling these valves to offer even more advanced features such as self-diagnostics and predictive maintenance capabilities.

Additionally, with the rise of Industry 4.0, data connectivity is becoming increasingly important. LVDT Proportional Valves could be expected to feature connectivity options that allow for integration with IoT systems. This integration would allow for real-time monitoring and control, enhancing systems' responsiveness and efficiency through data analytics.

Moreover, advancements in materials science may lead to the development of lighter, more durable components that can withstand a broader range of environmental conditions, including extreme temperatures and corrosive environments. This can greatly extend their application range further into aggressive industries like oil and gas extraction or chemical processing.

As eco-friendly initiatives gain momentum, manufacturers may also focus on developing LVDT Proportional Valves that promote energy efficiency and reduce waste in hydraulic systems. Such enhancements may include the development of valves designed to operate effectively with bio-hydraulic fluids or systems that minimize energy consumption through more intelligent control algorithms.

LVDT Proportional Valves are a cornerstone of modern industrial automation, offering unmatched precision and reliability across various applications. Their unique advantages derive from their ability to convert mechanical movements into precise control signals, thereby enhancing the performance of hydraulic systems.

As industries continue to evolve, the demand for high-performance control systems is only expected to grow. LVDT Proportional Valves are perfectly positioned to meet this demand, helping manufacturers, operators, and engineers realize their operational goals with efficiency and reliability. Understanding their functionality, benefits, and potential applications arms professionals with the knowledge to make informed decisions regarding their integration and use in various industrial contexts.

In summary, the significance of LVDT Proportional Valves cannot be overstated. They represent a critical juncture between mechanical engineering and digital control, maximizing both the efficacy of industrial systems and paving the way for future innovations in automation technologies.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!