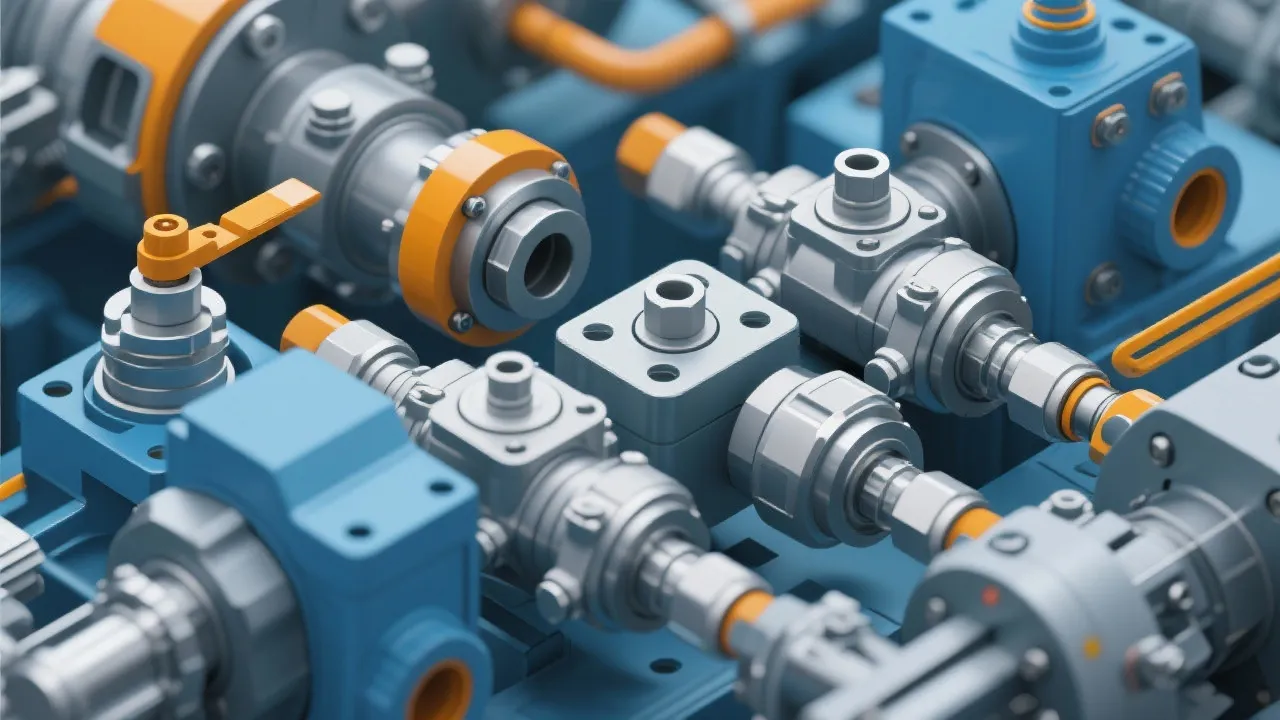

Rexroth Modular Valves are integral components in hydraulic systems, providing versatile solutions for fluid control and pressure regulation. Known for their reliability and efficiency, these valves are used globally in various industries, enhancing the performance and safety of machinery. This guide delves into their functionalities, applications, and selection criteria, offering expert insights into their role in modern industrial settings.

Rexroth Modular Valves serve as critical components in hydraulic systems, facilitating precise control over fluid dynamics. Renowned for their reliability and durability, these valves are a cornerstone in various industrial applications, from manufacturing to construction, ensuring machinery operates efficiently and safely. By integrating seamlessly with existing systems, Rexroth Modular Valves enhance operational capabilities through advanced control mechanisms and robust design.

These valves not only deliver teamwork with hydraulic cylinders and motors but also support electro-hydraulic controls, making them essential in a landscape where automation and efficiency are priorities. Unlike traditional valves, the modular approach allows for strategic expansion and adaptation, which is vital in an era of rapid technological advancement.

Constructed for durability and performance, Rexroth Modular Valves offer numerous benefits. Primarily, they ensure consistent pressure control, critical for maintaining system stability and preventing fluctuations that can lead to equipment failure or inefficiencies. The innovative design also incorporates features that minimize wear and tear, thereby extending the life of the equipment and reducing the frequency of replacements.

Additionally, their modular nature allows for tailored configurations, which can meet specific operational needs that vary from one setting to another. For example, users might require different flow rates, pressure settings, or responsiveness based on their machinery’s task demands, and the extensive range of valves in the Rexroth lineup addresses these needs. This flexibility is complemented by ease of installation and maintenance, which not only reduces downtime but also significantly lowers associated costs, allowing companies to maintain smoother operational rhythms and maximize productivity.

Rexroth Modular Valves comprise several key components that work cohesively to regulate hydraulic systems effectively. The primary elements include valve bodies, spools, springs, and seals, each playing a pivotal role in controlling fluid flow and pressure. The valve body houses the internal working elements and connects with other hydraulic parts, while spools, which are often designed to slide within the valve body, govern the flow pathways for the hydraulic fluid. Springs provide necessary resistance to ensure the spools return to their original positions when the system demands a reset, and seals are crucial for preventing leaks and maintaining pressure integrity.

Various configurations are available, ranging from standard valves that suit basic applications to more specialized setups equipped with adjustable flow rates and pressure settings. This attention to configurability means that whether a business is operating a small-scale agricultural machine or a large construction crane, there is a suitable Rexroth Modular Valve to match its hydraulic union. The advanced control capabilities provided by some models, such as proportional valves and load-sensing technology, allow for even greater adaptability and efficiency, meeting the demands of both general and niche industries.

The versatility of Rexroth Modular Valves makes them suitable for diverse applications across industries such as agriculture, construction, automotive manufacturing, marine, and even robotics. In agricultural machinery, these valves control hydraulic lifting systems, ensuring precise planting and harvesting, thereby directly impacting crop yields and profitability. For example, in precision farming, the ability to control hydraulic mechanisms with accuracy can reduce resource waste and promote sustainability.

In construction equipment, they govern the movement of large structural components, enhancing safety and efficiency. A hydraulic grabber or excavator relies heavily on reliable valve control to manage the heavy loads they handle while executing precise movements. With a robust valve system in place, operators can execute tasks with a level of dexterity and safety that manual systems simply cannot match.

Automotive manufacturers rely on these valves for precision in assembly lines and testing facilities, underscoring their adaptability and effectiveness. Hydraulic presses, which are pivotal in forming components, depend on the responsiveness and stability provided by Rexroth Modular Valves to maintain consistent performance through variable loads.

Moreover, these modular valves are increasingly being employed in robotics, where they facilitate fluid control in movements essential for assembly robots or robotic arms used in manufacturing settings. As industries continue to evolve, the demand for these adaptable hydraulic solutions will undoubtedly grow, and Rexroth is well-positioned to meet such requirements with its innovative product offerings.

When selecting Rexroth Modular Valves, several factors must be considered to ensure optimal performance and suitability. Assessing system pressure requirements is one of the most fundamental aspects, as each valve is designed to operate within specific pressure thresholds. This involves not only reviewing the maximum pressures the system will encounter but also understanding the variability that can occur during operation. Full engagement with the manufacturer's specifications is critical to maintain safety and functionality.

Fluid compatibility is another key consideration; the type of hydraulic fluid used can greatly influence the valve's performance and longevity. It is essential to choose materials that are resistant to the specific fluids used in the system, such as oil-based or water-based hydraulic fluids, to prevent deterioration and failure over time. Additionally, the temperature ranges in which the system operates must be evaluated, as extreme conditions can also impact valve integrity.

Environmental conditions play a pivotal role in the selection process as well. If the application occurs in outdoor settings or harsh environments, the chosen valves may require protection against dust, moisture, and other environmental factors that could lead to operational failures. This could involve selecting valves with protective casings or coatings to prolong their operational life.

Furthermore, configurations and available options like throttling or proportional control should be considered based on the specific demands of the application. It’s beneficial to take advantage of customization options offered by the manufacturer, such as integrating sensors or feedback mechanisms that allow for real-time adjustments to improve overall performance. Collaborating with suppliers who offer expert guidance in valve selection can enhance system performance and longevity, ensuring the components work harmoniously within the hydraulic system.

| Feature | Standard Valve | Adjustable Valve |

|---|---|---|

| Flow Control | Fixed | Variable |

| Pressure Limit | Preset | Adjustable |

| Application | Basic Hydraulic Systems | Complex, Custom Systems |

| Configuration Flexibility | Limited | Extensive, Modular |

| Maintenance Needs | Standard | More Regular but Less Downtime |

| Cost | Lower Initial Investment | Higher Initial Cost, Long-term Savings |

This comparison highlights essential parameters that users should evaluate when choosing between standard and adjustable Rexroth Modular Valves. The decision often hinges on the specific application needs, desired flexibility, and budget considerations. While standard valves may present an initial cost benefit, the potential for higher efficiency and adaptability offered by adjustable valves can lead to significant long-term savings and enhanced performance.

Industry trends indicate a growing demand for Rexroth Modular Valves, driven by advancements in automation and the increasing adoption of smart manufacturing technologies. According to a report by the International Federation of Robotics, industries are investing heavily in upgrading hydraulic systems to enhance precision and efficiency, underscoring the strategic importance of high-quality valves in achieving these objectives. These trends suggest a broader movement towards integrating digital technologies with hydraulic systems, further enhancing their precision through data analytics and real-time monitoring.

Moreover, the emphasis on environmental sustainability and energy efficiency has given rise to a preference for hydraulic solutions that minimize energy consumption while maximizing performance. In this context, Rexroth Modular Valves' ability to provide accurate control helps meet the industry's green initiatives by improving hydraulic system efficiency and reducing overall energy expenditures. As automation solutions and smart technologies become more prevalent, they also foster a competitive landscape where efficiency, precision, and reliability are paramount.

Additionally, as global supply chains adjust in response to rapidly changing market conditions, industries are reevaluating their operational strategies. Companies are increasingly leveraging modular and scalable solutions such as Rexroth Modular Valves to respond to these changes, allowing for prompt adjustments in production methods and efficiency measures. Overall, the future of Rexroth Modular Valves is bright, as they continue to evolve alongside industry needs and technological advancements.

Rexroth Modular Valves epitomize precision and reliability in hydraulic systems, serving as integral components necessary for modern industrial applications. By enabling efficient fluid control and offering customizable solutions, these valves support the intricate demands of various sectors. Collaborating with Rexroth not only assures users of having the foremost hydraulic solutions readily available but also emphasizes the commitment to innovation and excellence that Rexroth stands for.

As industries continue to innovate and adapt to the challenges of automation and sustainability, the role of Rexroth Modular Valves in enhancing machinery performance remains critical. Through their ongoing evolution and responsiveness to market needs, these valves will undoubtedly contribute to achieving operational excellence, making them a valuable asset in any hydraulic system. By investing in such advanced technology, businesses ensure they are not just keeping pace with current trends but also setting the stage for future growth and efficiency.

In conclusion, Rexroth Modular Valves not only represent a blend of robust engineering and innovation but also signify a commitment to the future of hydraulic control technology. Their strategic importance in various applications and industries underscores their enduring value in achieving a higher standard of operational efficiency.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!