The Lvdt Proportional Valve revolutionizes fluid control in various industrial applications by offering precision and adaptability. This article delves into the functions, benefits, and technical specifics of these valves, which integrate Linear Variable Differential Transformers (LVDTs) to provide exceptional performance control, translating linear motion into electrical signals to regulate flow direction and rate with remarkable accuracy and responsiveness.

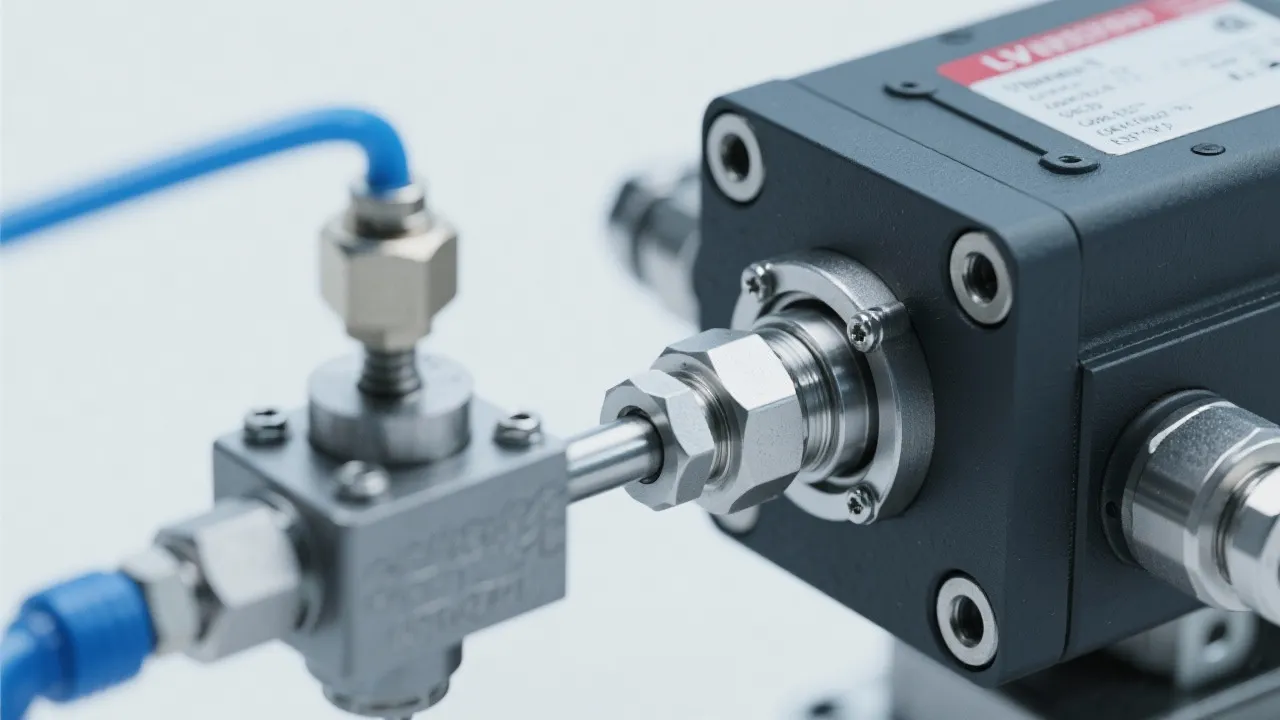

The Lvdt Proportional Valve represents a significant advancement in the realm of fluid control technologies. These valves are equipped with Linear Variable Differential Transformers (LVDTs), crucial components that convert mechanical linear motion into electrical signals. This conversion enables the precise control of fluid velocity and direction in a multitude of industrial settings, from pneumatic systems to hydraulic machinery. The versatility of LVDT technology makes it an essential factor in enhancing the efficiency and efficacy of fluid handling systems across diverse applications.

Lvdt Proportional Valves utilize LVDTs for nuanced feedback, facilitating fine-tuned adjustments based on current operational requirements. The LVDTs generate a proportional electrical output linked with stem positioning, allowing for exact control over fluid flow. Unlike traditional valves that may rely on binaries (open or close), Lvdt Proportional Valves offer a spectrum of operational states, enhancing system efficiency and response rate. The precision of fluid control directly influences the performance and safety of the entire system, making the implementation of Lvdt Proportional Valves a worthwhile investment in any advanced industrial application.

To delve deeper into their functionality, LVDTs operate based on the principle of electromagnetic induction. They consist of a primary coil and two secondary coils, where a metallic core moves within these coils in response to the position of the valve stem. As this core moves, it alters the magnetic flux linkage in the secondary coils, generating a differential voltage output that correlates with the linear displacement. This high-fidelity feedback allows the control system to position the valve accurately, ensuring appropriate fluid delivery under varying conditions.

These valves are characterized by several critical specifications that define their performance capabilities and suitability for various applications:

This combination of features underscores their effectiveness where precision is paramount. For environments where response time and accuracy can greatly affect productivity, such as in automated manufacturing lines or complex hydraulic systems, the inclusion of Lvdt Proportional Valves can significantly enhance overall performance.

Lvdt Proportional Valves find applications in numerous industries, including:

The primary benefits of these valves include increased efficiency, reduced energy consumption, and minimized wear and tear on mechanical components due to their ability to operate smoothly and consistently over extended periods. Organizations leveraging these technologies can expect not just immediate operational improvements but also long-term savings due to decreased maintenance needs and extended equipment lifecycles.

A comparative view of fluid control technologies shows that Lvdt Proportional Valves hold several advantages over traditional valves:

| Parameter | Lvdt Proportional Valve | Traditional Valve |

|---|---|---|

| Precision Control | High - Provides continuous control across a range of demands | Medium - Limited to binary states, compromising on gradation |

| Response Time | Fast - Quick adaptation to changes, ideal for dynamic environments | Moderate - Slower adjustment speeds, which may lead to inefficiencies |

| Durability | High - Built for longevity in demanding settings, providing reliable performance | Varies - Often less robust in harsh conditions, requiring frequent replacements |

| Energy Efficiency | Low power consumption, contributing to lower operational costs | Higher power requirements, potentially increasing energy expenses |

In industries where precision and reliable performance are essential, the Lvdt Proportional Valve offers significant benefits over more traditional options.

Despite their advantages, the adoption of Lvdt Proportional Valves also brings challenges, primarily in terms of cost and system complexity. The initial investment in these sophisticated components may be higher than simpler valve systems, which can deter potential users. However, the long-term savings and efficiency improvements often justify this upfront cost. Additionally, their integration into existing systems requires careful planning and expertise to maximize their potentials fully and avoid operational issues or efficiency losses.

Implementation challenges can include the necessity for highly-skilled personnel to program and maintain the proportional control systems, as well as the need for enhanced training for operators who must learn to work with these advanced components effectively. Furthermore, ensuring compatibility with existing infrastructure is critical; thus, thorough analysis and consideration during the design phase are necessary to avoid costly retrofitting later on.

Moreover, ongoing monitoring and tuning of systems using LVDT Proportional Valves may be needed to adapt to changing operational conditions or to optimize performance further. This can introduce additional operational overhead, although many manufacturers offer support and advanced software solutions aimed at minimizing these challenges.

The utilization of Lvdt Proportional Valves signifies a pivotal step forward for industries that demand advanced fluid control solutions. By choosing these robust, precise, and reliable valves, organizations are not only investing in current operational effectiveness but also laying the groundwork for future technological advancements. With ongoing innovations in LVDT technology and control systems, the potential applications for these valves will likely continue to expand, further driving improvements in automation and efficiency across various sectors.

In conclusion, the integration of Lvdt Proportional Valves into fluid control systems represents a transformative approach to managing fluid dynamics more effectively. By harnessing their capabilities, industries can achieve greater efficiency, enhanced safety, and better overall operational harmony, paving the way for more innovative and effective solutions in the future.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!