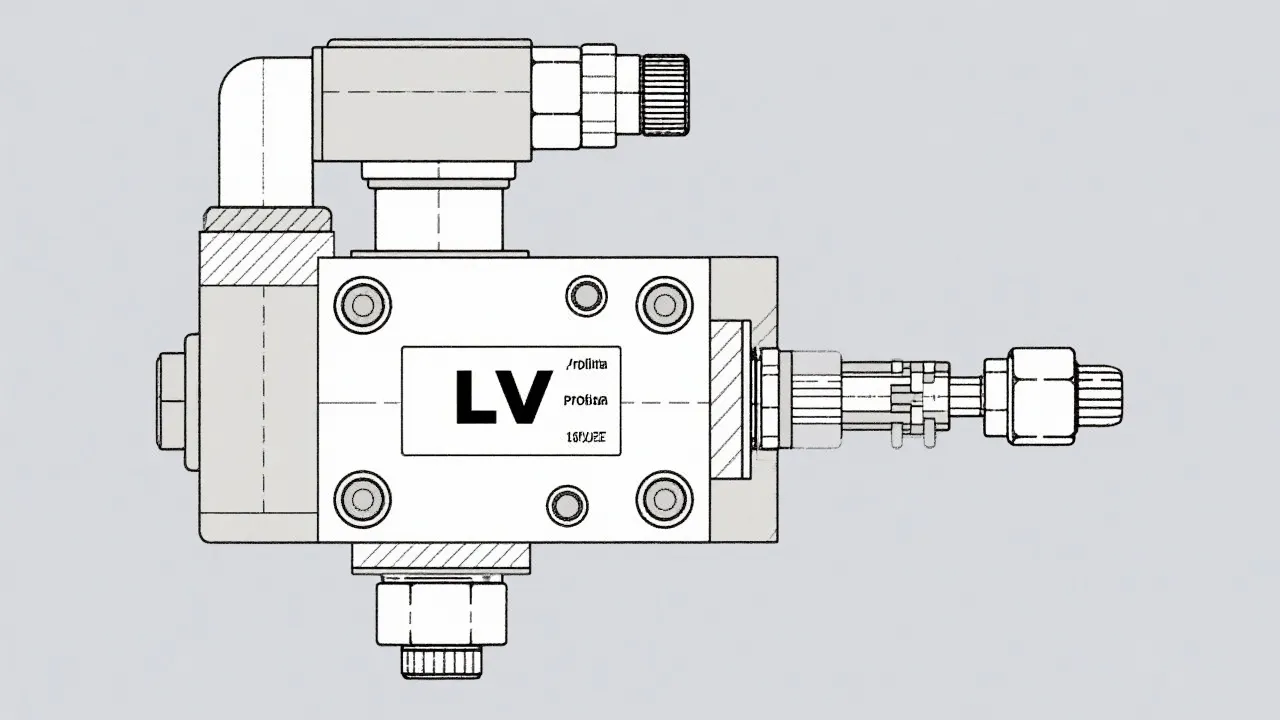

This guide provides an in-depth analysis of Lvdt Proportional Valves, critical components in hydraulic systems for precise flow control. Known for their accuracy and efficiency, these valves integrate LVDT sensors for seamless electronic command input into mechanical motion output, ensuring optimal performance in high-demand applications like industrial machinery and aerospace.

Lvdt Proportional Valves serve as an essential component in modern hydraulic systems, ensuring precise fluid regulation that meets the critical demands of various industries. Known for their reliability and accuracy, these valves integrate with Linear Variable Differential Transformers (LVDT) to convert electronic signals into mechanical movement, allowing for enhanced control over fluid flow. It is these properties that make them indispensable in applications requiring robust and accurate flow management, such as industrial machinery, aerospace engineering, automotive systems, and even advanced robotics.

As industries continue to push the boundaries of what is possible with automation and precision engineering, the need for components that can deliver exceptional performance and adaptability has never been greater. Lvdt Proportional Valves meet this demand, merging sophisticated technology with practical functionality. In this exploration, we will delve deeper into the specific characteristics, benefits, applications, comparisons, and considerations to keep in mind when utilizing these complex yet vital hydraulic components.

The Lvdt Proportional Valve is characterized by its capacity to provide precise control of hydraulic systems. This precision stems from the integrated LVDT, which operates as a feedback element ensuring real-time adjustments and optimal system performance. Some key benefits include:

The versatility of Lvdt Proportional Valves makes them suitable for a wide range of applications. Notably, they are heavily utilized in the industrial and aerospace sectors, among others:

The integration of LVDTs into proportional valves offers a significant edge over traditional hydraulic valves. Below is a comparison highlighting the distinctions:

| Aspect | Lvdt Proportional Valves | Traditional Hydraulic Valves |

|---|---|---|

| Control Precision | High precision due to real-time feedback | Limited precision without feedback integration |

| Response Time | Quick response to electronic signals | Slower due to mechanical adjustments |

| Maintenance | Requires minimal maintenance due to fewer mechanical parts | Higher maintenance needs due to mechanical wear |

| Energy Efficiency | More energy-efficient due to precise fluid control | Less energy-efficient, often resulting in wasted energy |

| Installation Flexibility | Can be installed in a variety of configurations | Typically requires specific conditions and setups |

| Cost of Ownership | Lower overall costs due to increased longevity and reduced downtime | Higher costs associated with frequent repairs and replacements |

When selecting a supplier for LVDT Proportional Valves, factors such as price, reliability, and supplier reputation are crucial. Here are essential considerations to keep in mind:

The primary advantage is their accuracy and responsiveness, allowing for precise control in complex hydraulic systems. This results in improved machinery performance and process efficiency.

While widely applicable, the suitability depends on the specific requirements of the hydraulic system and the environment in which it operates. Factors such as pressure ratings, fluid types, and environmental conditions must be considered.

The LVDT provides real-time position feedback, which enhances valve control precision and system efficiency. This feedback loop allows the system to adapt instantly to changes, ensuring optimal performance under varying loads.

Key industries include aerospace, automotive, manufacturing, robotics, and medical devices. Each of these sectors demands high precision and reliability in their fluid control systems to maintain safety and operational efficiency.

While the benefits are significant, potential downsides include initial costs and the need for specialized knowledge for integration. However, these downsides are often outweighed by performance benefits in the long run.

Emerging trends include the increasing use of smart technology and IoT integrations in hydraulic systems. This will likely enhance monitoring capabilities, predictive maintenance, and overall efficiency of fluid control operations.

Lvdt Proportional Valves stand at the forefront of hydraulic innovation, transforming electronic inputs into precise mechanical operations. Their development marks a significant leap in control accuracy, reliability, and efficiency. Whether applied in industrial settings, advanced aerospace systems, or automated manufacturing, these valves are integral in driving advancements in fluid control technology. As industries evolve towards greater automation, the natural synergy between LVDT technology and hydraulic systems paves the way for smarter, more efficient factories and machines. When selecting such a vital component, understanding the specifications and functionalities ensures optimized system integration and performance. With the right knowledge and support, users can leverage the full potential of LVDT Proportional Valves to advance their operational goals and industrial capacities.

As the demand for precision control in hydraulics continues to grow, so too does the technology behind LVDT Proportional Valves. Innovations in materials, sensors, and electronic control systems are paving the way for new possibilities. Some notable developments include:

Looking ahead, the potential for LVDT Proportional Valves is vast. As industries pivot towards automation and enhanced efficiency, the role of these valves will only expand. Future prospects include:

Overall, understanding the technological advancements and future prospects related to LVDT Proportional Valves is essential for industries seeking to harness their capabilities. By staying informed and adapting to these changes, organizations can optimize their operations, improve performance, and contribute significantly to the evolution of fluid control technologies.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!