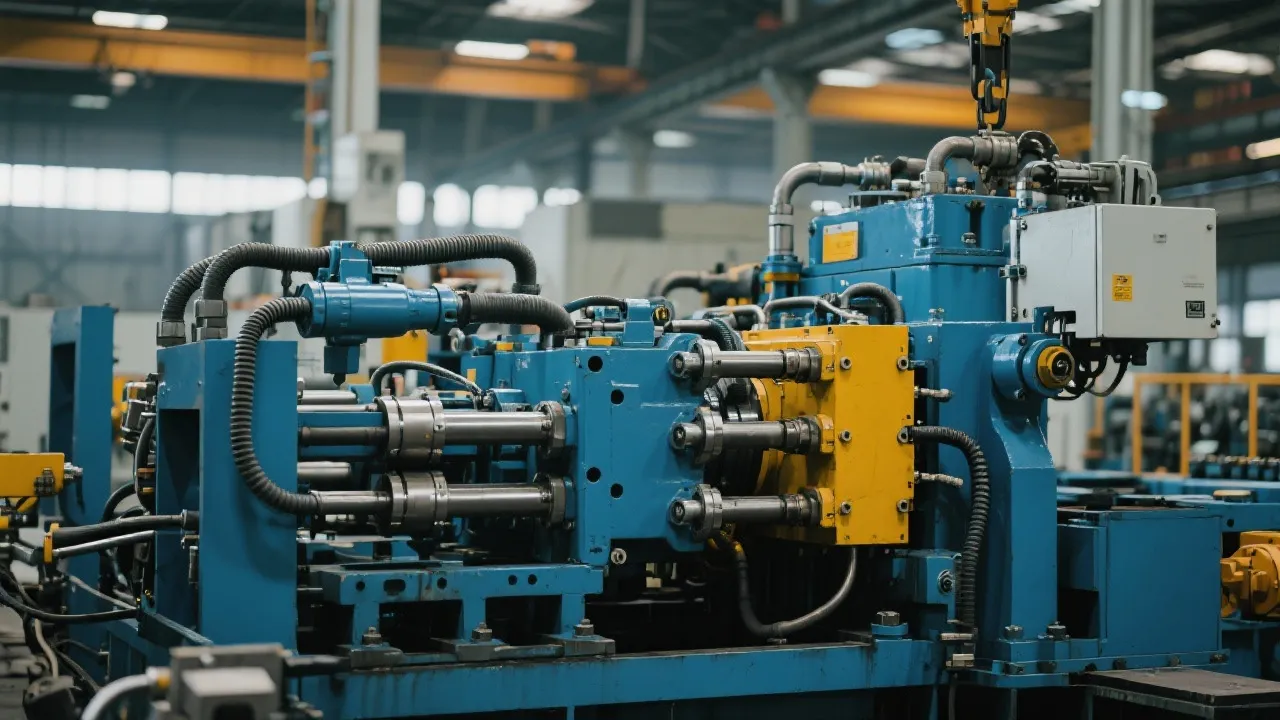

Hydraulic Cartridge Valves play a significant role in modern hydraulic systems, offering a compact solution for fluid control. These valves are integral to various industries due to their versatility, robustness, and efficiency in directing hydraulic fluid flow. With rapid advancements in hydraulic technology, understanding these components' specifications and applications is crucial for engineers and manufacturers.

Hydraulic Cartridge Valves are a pivotal component in the world of fluid power systems. Designed to manage the flow and pressure of hydraulic fluid within a circuit, these valves serve a multitude of applications across industries such as construction, agriculture, and manufacturing. They are critical in controlling the hydraulic systems that drive machinery in various settings, operating as precise control mechanisms for both high-pressure applications and high-flow scenarios. Unlike traditional valves, hydraulic cartridge valves provide a more compact and modular solution, allowing for significant advancements in design and functionality.

The execution of hydraulic systems heavily relies on the efficiency provided by these components. The ability of hydraulic cartridge valves to simplify complex maneuvers by providing a reliable interface for fluid control—along with their ability to handle higher pressures—enhances performance in equipment that ranges from simple hydraulic tools to complex construction machinery. Their versatility, combined with a robust build, makes them essential for efficient hydraulic system designs, paving the way for innovation in mechanical engineering and application.

The nature of hydraulic cartridge valves contributes to their increasing popularity, as they can be easily embedded within machinery designs or utilized in retrofitting older systems with updated technology. This development enhances overall equipment effectiveness while promoting energy conservation standards that are vital in today's industrial landscape. Thus, understanding how these valves operate and the advantages they bring is crucial for engineers, manufacturers, and operators alike.

Hydraulic Cartridge Valves streamline the design of hydraulic systems by integrating essential functions into a compact unit. They often incorporate various functions such as check, relief, flow control, and directional control, which makes them a flexible solution in fluid movement management. The engineering of these valves is highly specialized to ensure precise fluid control, which is crucial for optimizing system performance and reliability. Key benefits include:

In the context of evolving industrial technologies, hydraulic cartridge valves also benefit from advanced design techniques that leverage sophisticated simulation methods, allowing for the optimization of flow characteristics and pressure drops. These advancements contribute to the ongoing efforts in hydraulic engineering to reduce energy consumption and enhance efficiency in system operations.

The widespread use of hydraulic cartridge valves is due to their adaptability and robust performance under variable conditions. Here are a few key sectors where these valves have made a significant impact:

The versatility of hydraulic cartridge valves also extends to niche applications, including renewable energy systems—where they assist in controlling hydraulic functions in systems such as wave energy converters and advanced solar tracking systems. The trend towards automation and increased efficiency across all sectors continues to drive innovation in cartridge valve functionality and application.

Selecting the appropriate hydraulic cartridge valve requires understanding the specific needs of your application. A multitude of factors comes into play when making this decision, including but not limited to pressure rating, flow capacity, and environmental conditions. Each of these parameters plays a vital role in ensuring optimal functioning and avoiding unexpected failures. Here's a deeper look at what to consider when choosing hydraulic cartridge valves:

Consulting with industry experts or relying on manufacturers with proven track records can prevent costly errors and enhance system performance. Drawing on the experience of professionals can provide insights on the intersection of material choice and valve design that ultimately supports operational sustainability and efficiency, ensuring that equipment meets or exceeds industry standards.

| Parameter | Description |

|---|---|

| Pressure Rating | Specifies the maximum pressure the valve can handle, crucial for ensuring compatibility with system pressure. |

| Flow Capacity | Indicates the valve's capability to handle specific fluid flow rates, which affects the efficiency of the hydraulic system. |

| Response Time | Refers to the speed at which the valve reacts to input signals, critical for applications requiring high precision. |

| Temperature Tolerance | Indicates the operational temperature range within which the valve can function effectively. |

| Material Composition | Determines the valve's suitability for different environmental demands, such as high temperature or corrosive environments. |

| Sealing Performance | Reflects how well the valve prevents leakage and maintains fluid integrity under pressure. |

To ensure prolonged functionality and efficiency of hydraulic cartridge valves, regular maintenance and correct operational practices are a must:

As industries increasingly focus on sustainability and reducing environmental impacts, hydraulic cartridge valves are evolving. Manufacturers are developing more eco-friendly hydraulic fluids and materials, reducing environmental footprints while ensuring the same level of performance and durability. Additionally, advancements in valve design aimed at enhancing efficiency are allowing systems to operate at lower pressures and with reduced energy consumption.

The incorporation of smart technology in hydraulic systems also promises to revolutionize how hydraulic cartridge valves are monitored and managed. Sensors embedded in the valves can provide real-time data on performance metrics, allowing for quicker responses to any issues that may arise. Predictive maintenance models rely on this data, helping prevent unexpected downtime and reducing operational costs.

Moreover, with the rise of automation, the demand for more complex and integrated hydraulic systems is increasing. Hydraulic cartridge valves are set to play a crucial role in these developments, offering the necessary versatility and performance needed to support robotic systems, powered actuators, and autonomous machinery. Future trends also indicate a movement towards more standardized valve designs, making replacements and upgrades easier across different machinery and sectors.

Hydraulic cartridge valves are essential elements in hydraulic systems, offering a combination of compact design, durability, and versatility that suit a wide range of applications. From construction machinery to agricultural equipment and automation, their ability to provide reliable fluid control is critical in enhancing productivity and efficiency. Understanding the intricacies behind their functionality, selection, and maintenance can greatly benefit operators, engineers, and companies involved in hydraulic applications.

As technology continues to evolve, so too will the capabilities of hydraulic cartridge valves. Staying informed about industry advancements and emerging trends will enable stakeholders to harness the full potential of these vital components in their hydraulic systems. The ongoing integration of digital technology, coupled with a focus on sustainability, promises a bright future for hydraulic cartridge valve implementation across numerous applications.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!