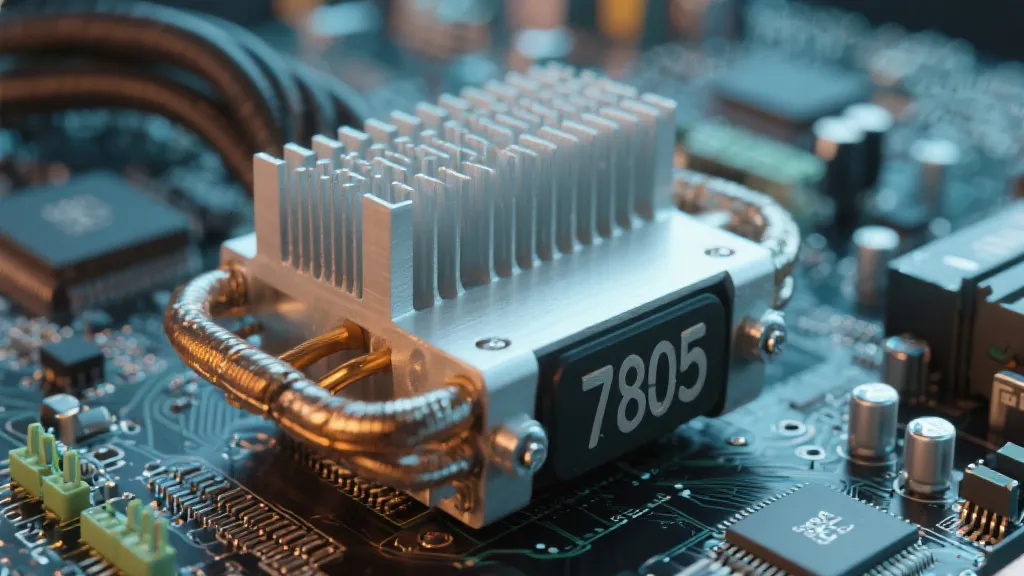

This guide explores the 7805 heatsink, a critical component in electronic assemblies for dissipating heat produced by devices like voltage regulators. Known for its efficiency, the 7805 heatsink plays an essential role in maintaining optimal temperatures in circuit boards, thus ensuring reliability and longevity in electronic devices. Learn about specification details, integration in circuits, and benefits in enhancing device performance.

The 7805 heatsink is a pivotal component in modern electronics, particularly valued for its ability to effectively dissipate heat from voltage regulators and other heat-generating components on a circuit board. This capability helps to maintain stable temperatures, which is essential for the reliability and efficiency of electronic devices. As numerous applications and industries increasingly rely on electronic components, understanding the function and benefits of the 7805 heatsink becomes even more critical.

As electronic devices become smaller and more compact, the need for efficient heat dissipation becomes even more pressing. The 7805 voltage regulator, a common component in various power supply circuits, is known to generate significant heat during its operation, particularly when there is a large voltage drop from input to output. Consequently, a 7805 heatsink not only optimizes the performance of the voltage regulator but also enhances the overall robustness of the circuit, making it an irreplaceable asset in the field of electronics.

The 7805 heatsink is designed with several features that make it suitable for various uses. It typically requires a compatible attachment to 7805 type linear voltage regulators, allowing for efficient heat transfer. The material, often aluminum, offers excellent thermal conductivity while keeping the component lightweight and affordable. Additionally, the dimensions and fin design are optimized to enhance the surface area for better heat dissipation without compromising space in compact circuit designs.

In applications where space is limited, engineers can choose from a variety of heatsink styles, including extruded heatsinks, stamped heatsinks, or even custom-made designs. Each type has its advantages depending on the thermal performance required, manufacturing costs, and the specific application. For instance, extruded heatsinks are particularly popular due to their ease of production and reliable performance.

| Feature | Description |

|---|---|

| Material | Aluminum for lightweight and efficient thermal conductivity. |

| Compatibility | Suitable for 7805 linear voltage regulators. |

| Design | Finned structure to maximize heat dissipation. |

| Dimensions | Varies based on application, typically between 20mm and 60mm in height. |

| Thermal Resistance | Measured in °C/W, indicating how effectively the heatsink can dissipate heat. |

| Mounting Options | Includes mechanical fastening and thermal adhesive pad options. |

Integrating a 7805 heatsink involves several steps to ensure optimal performance. First, proper placement on the circuit board is crucial, ideally near the heat source but allowing for adequate air circulation. Attachment methods vary, often involving mechanical fasteners or adhesive thermal pads that secure the heatsink to the chip. Ensuring good contact between the surfaces is critical for effective thermal transfer. Careful consideration of the circuit layout and airflow dynamics is vital to prevent overheating and ensure device longevity.

For optimal integration, it’s advisable to utilize thermal paste or thermal interface materials (TIMs) between the 7805 voltage regulator and the heatsink. This not only fills any microscopic air gaps that reduce thermal conductivity but also aids in faster heat transfer from the regulator to the heatsink. The effectiveness of a heatsink can also be improved by examining its orientation in relation to airflow patterns within the enclosure; vertical mounting may increase convection efficiency.

In high-power applications, multiple heatsinks might be employed, or a larger heatsink may be considered to ensure that the total thermal load is adequately managed. Additionally, the use of fan-assisted cooling can significantly enhance the heat dissipation capabilities of a heatsink assembly, particularly in environments where ambient temperatures are high or airflow is limited.

The primary benefit of utilizing a 7805 heatsink is its ability to prolong the lifespan of electronic components by preventing overheating. By maintaining lower operational temperatures, the risk of thermal-related failures is significantly reduced. Moreover, this contributes to improved performance and reliability of the device. Enhanced thermal management also allows for higher power densities and compact designs, which are increasingly crucial in modern electronics applications.

Furthermore, using a heatsink can also minimize the need for additional cooling solutions such as active fans or more expensive thermal management options, effectively lowering overall system costs. A well-designed thermal management solution that includes a heatsink may also enable the use of more cost-effective components throughout the design process, as the system can operate within safe thermal limits even under heavy load conditions.

Moreover, incorporating a heatsink can support higher efficiency in power conversion, which is essential for battery-operated devices where energy savings are paramount. In systems where minimizing power loss is critical, such as in renewable energy applications or electric vehicles, the role of the 7805 heatsink becomes even more significant.

The versatility of the 7805 heatsink means it finds usage in a diverse range of applications across different industries. Key application scenarios include:

To maximize the effectiveness of the 7805 heatsink, several best practices should be followed:

The emergence of new technologies and materials is poised to revolutionize thermal management, impacting the role of heatsinks significantly. Innovations like advanced composite materials that offer improved thermal conductivity and reduced weight are being developed and may soon replace traditional aluminum in some applications. Moreover, as the demand for miniature devices grows, integrated solutions that combine heatsinks with electronic components on a single chip may become prevalent, leading to more efficient space utilization and improved thermal performance.

Additionally, with the rise of electric vehicles and renewable energy solutions, the requirements for advanced thermal management strategies are set to increase. Electronic components must handle higher thermal loads, necessitating more robust and effective heatsink designs. Companies in the electronics industry are also exploring smarter thermal management systems that dynamically adjust cooling requirements based on real-time data, optimizing performance while minimizing energy consumption.

Furthermore, the Internet of Things (IoT) has introduced a myriad of new applications that require precise thermal management due to their continuous operation in various environmental conditions. The integration of IoT with advanced analytics may also lead to predictive maintenance strategies for thermal management systems, increasing overall reliability and reducing costs associated with downtime.

In conclusion, the 7805 heatsink plays a vital role in the thermal management of electronic devices. Understanding its application, integration, and the benefits it provides is essential for electronics designers and engineers. As technology continues to evolve, the demand for proficient thermal management solutions like the 7805 heatsink will persist, underscoring its importance in achieving efficient and reliable electronics systems. The ongoing developments in materials and design will further enhance the role of heatsinks, making it imperative for professionals in the field to stay abreast of advancements to apply them effectively in future projects.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!