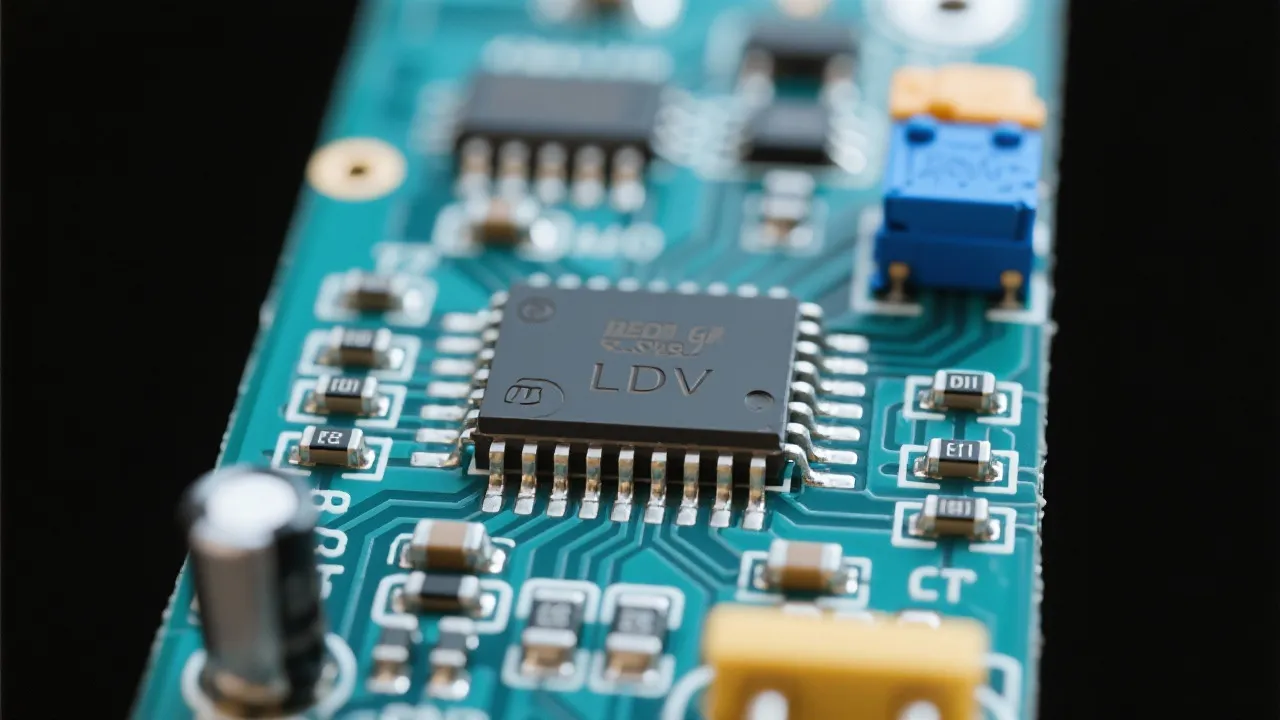

In the evolving realm of electronics, Infineon's Low Dropout Regulators (LDOs) have emerged as pivotal in achieving efficient power management. Known for their precision and reliability, these voltage regulators are crucial in minimizing power loss across various applications, including portable devices and communication infrastructure, marking significant advancements in electronic component technology.

Infineon's Low Dropout Regulators, or LDOs, represent a cornerstone in the effective distribution of power within electronic circuits. LDOs are critical in scenarios where efficient power conversion is necessary without significant power loss or heat generation. As electronics continue to miniaturize, the role of LDOs becomes even more vital, ensuring steady voltage outputs even as input voltage diminishes close to output levels. This consistency allows for enhanced performance in various electronic applications, especially as the number of devices relying on precise power management rapidly escalates.

LDOs are essential for maintaining efficiency in power supply circuits, providing stable output despite low differential voltage. This efficiency is critical in battery-powered devices where preserving power is paramount. Infineon's LDOs stand out due to their ability to offer minimal power waste during transmission, making them ideal for compact and energy-sensitive applications like smartphones, tablets, and wearable technology. Furthermore, their design supports low noise operation, which is crucial in audio and RF applications where signal integrity is paramount.

Infineon LDOs find use in multiple sectors. In consumer electronics, these regulators support the longevity of battery life by minimizing power consumption. In telecommunications, Infineon's LDOs ensure that sensitive communication equipment performs reliably under varying conditions, supporting robust infrastructure with reduced downtime. Their role extends into automotive systems, particularly as vehicles becomes increasingly reliant on advanced electronics for navigation, safety systems, and infotainment. The demand for resilience and precision in these electronic systems has never been higher, which makes the efficiency these regulators provide even more crucial. They ensure that high-performance applications, such as electric drive systems and battery management units, operate effectively in diverse environments.

Recent advancements in Infineon's LDO technology have led to enhanced power regulation solutions. Key innovations include improved thermal performance, which allows for greater operational reliability even in high-temperature environments. Lower noise output is another significant advancement, making them suitable for audio applications where maintaining signal clarity is necessary. Increased power density enables these LDOs to deliver more consistent performance while occupying less board space—a vital factor in the design of modern electronic devices. Infineon's commitment to environmental sustainability is reflected in the design of their LDOs, which are engineered to consume less power and, consequently, have a smaller carbon footprint. This eco-conscious approach aligns not only with regulatory expectations but also with the growing consumer demand for green electronics.

| Model | Key Features | Applications |

|---|---|---|

| TLV767 | Ultra-low noise output, fast transient response | Audio devices, RF modules |

| TLV710 | High power supply rejection, extended temperature range | Automotive equipment, industrial sensors |

| TLV700 | Low quiescent current, high current output capability | Mobile devices, portable electronics |

| TLV900 | Enhanced load transient response, integrated thermal protection | Wearable devices, IoT applications |

| TLV803 | Low dropout voltage, stable operation over temperature | Medical devices, industrial automation |

When designing with LDOs, several factors must be taken into account to optimize performance. Dropout voltage is a primary consideration; it refers to the minimum voltage difference between the input and output that guarantees stable operation. Designers should select an LDO with a dropout voltage appropriate for the application to ensure efficient performance. Additionally, load current is critical; LDOs must be able to handle the maximum expected load to prevent performance degradation.

Another design aspect to consider is the power dissipation within the LDO. High power dissipation can lead to overheating and potentially damage the device. Thermal management, including adequate heat sinking or layout considerations to facilitate heat dissipation, is essential. Additionally, understanding the LDO's power supply rejection ratio (PSRR) will help in determining how well it can filter out noise from the input voltage, which is essential for sensitive analog circuits.

While Infineon LDOs offer many benefits, there are inherent challenges associated with integrating LDOs into designs. One significant challenge is managing thermal performance in high current applications. The more current the LDO has to deliver, the more heat it generates. A robust thermal management strategy must be employed to mitigate the effects of heat. For instance, the use of thermal vias and copper planes on PCB can help spread heat and maintain junction temperatures within specifications.

Another potential challenge is instability in high-ESR output capacitors. LDOs can become unstable if not properly designed with the correct output capacitor, leading to oscillations. It is essential to follow Infineon's recommendations regarding capacitor types and values to ensure stable operation. Designers may need to experiment with capacitor types, such as tantalum or ceramics, to find an optimal solution that minimizes ESR while maintaining performance.

When integrating Infineon LDOs into electronic designs, following best practices can significantly enhance performance. Begin by evaluating the application's specific requirements, including voltage levels, load current, and thermal constraints, to select the appropriate LDO model. Next, pay attention to PCB layout; short traces between the LDO and the load minimize parasitic inductance and resistance, resulting in better performance. Adequate decoupling capacitors should be placed close to the LDO's output to stabilize the voltage and reduce noise.

Additionally, ensure that the LDO has sufficient headroom under all operating conditions. This practice guarantees reliable operation, particularly as the input voltage approaches the output voltage levels. Lastly, regular testing under different load conditions and temperatures will help identify any quirks in operation that may arise and ensure functionality across all scenarios.

Q: What sets Infineon LDOs apart from other brands?

A: Infineon LDOs offer superior efficiency, precision, and reliability. They are designed to minimize power loss while maintaining optimal performance across a range of environments, catering to both standard and demanding applications.

Q: How do LDOs benefit portable device manufacturers?

A: LDOs greatly extend battery life by efficiently managing power consumption, making them indispensable for portable devices under compact design constraints. Their low quiescent current and low dropout voltage translate to longer-lasting devices, which is a crucial selling point in competitive markets.

Q: Are there specific conditions for using Infineon LDOs?

A: While Infineon LDOs are versatile, they are highly beneficial where low dropout voltage and high efficiency are essential, such as in battery-operated devices and precision electronics. Their applications can vary widely; however, the performance is optimized when the conditions are aligned with the product specifications and recommendations.

Q: How does temperature impact LDO performance?

A: Temperature can significantly affect the performance of LDOs, impacting both output voltage stability and overall efficiency. Higher operating temperatures can increase power dissipation, leading to thermal shutdown if not managed correctly. It's vital to choose LDOs that are rated for the operational temperature range of the application and to implement effective thermal management strategies.

Q: What role do decoupling capacitors play in LDO circuits?

A: Decoupling capacitors are crucial in LDO circuits to filter out noise and stabilize the output voltage. They help manage load transients and provide necessary energy during momentary fluctuations in load, ensuring a stable and reliable output from the LDO. Choosing the right capacitor type and value is essential to maintain performance.

Infineon LDOs are at the forefront of power management technology, offering innovative solutions that enhance device longevity and efficiency. As electronic devices and systems become more sophisticated, reliable power regulation provided by these LDOs will continue to play a crucial role in the industry's evolution, supporting sustainable and high-performance designs. Their contribution to improving battery longevity in consumer electronics, ensuring signal integrity in telecommunications, and optimizing performance in automotive and industrial applications signifies their critical value across multiple domains. With ongoing advancements in technology, Infineon LDOs are likely to evolve in their capacity to meet future power management challenges, sustaining today's rapidly changing electronic landscape.

As we look ahead, the demand for advanced power management solutions will only continue to grow. Key trends influencing the future of LDOs include the rise of electric vehicles, the expansion of the Internet of Things (IoT), and the increasing miniaturization of electronic devices. In electric vehicles, LDOs will be instrumental in managing power distribution and supporting the various sensors and control systems necessary for efficient operation. Similarly, in the IoT space, the need for low-power, efficient designs will amplify the role of LDOs as they serve to manage power for a myriad of connected devices.

Moreover, advancements in semiconductor technology are leading to new materials and manufacturing techniques that enhance LDO performance. Silicon carbide (SiC) and gallium nitride (GaN) technologies are beginning to emerge, enabling LDOs to operate at higher voltages and efficiencies. As these technologies mature, we can anticipate LDOs that deliver even greater performance metrics while supporting smaller and more compact designs.

Finally, the continued emphasis on energy efficiency and sustainability will push manufacturers toward LDOs that not only perform well but also conform to eco-friendly standards. As societies worldwide grapple with climate change and energy consumption, companies need to be proactive in adopting solutions that contribute to a more sustainable future. Infineon's focus on creating environmentally-conscious LDO products will help pave the way for greener electronics that maintain high performance and efficiency.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!