Introduction to Sj 170t

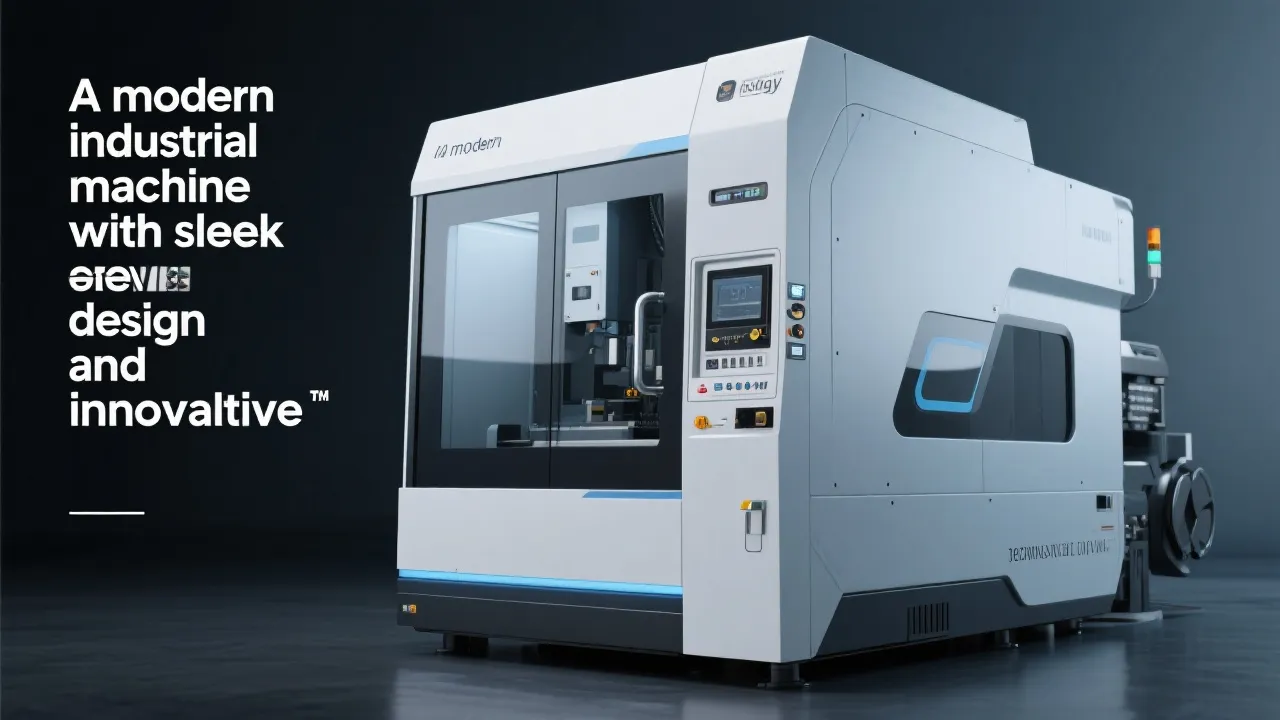

The industrial machinery landscape is constantly evolving, with advancements geared towards enhancing production efficiency and reducing operational costs. Among these innovations, the Sj 170t machine stands out, lauded for its superior performance and versatility. This article explores the intrinsic details of the Sj 170t and its applications in various manufacturing domains, providing an expert's perspective on its place in today's industrial ecosystem. The Sj 170t is at the cutting edge of technology, serving industries ranging from automotive to consumer goods, and its significance grows as the demands of production change and develop.

Key Features of the Sj 170t

At the core of the Sj 170t is its state-of-the-art design, which integrates cutting-edge technology to meet diverse industrial needs. With an emphasis on precision and reliability, the machine offers unparalleled performance. Key features of the Sj 170t include:

- High Efficiency: Engineered to optimize workflow, the Sj 170t enhances productivity by minimizing downtime and maximizing output. The machine's ability to constantly operate at peak performance ensures that production schedules are met with ease, contributing to overall efficiency in the manufacturing process.

- Durable Construction: Crafted with top-tier materials, it ensures longevity and sustained performance, minimizing the need for frequent maintenance. This durability translates into cost savings over the life of the machine, as businesses face fewer unexpected repairs and replacements.

- Precision Control: Equipped with advanced control systems, it allows for precise adjustments, catering to intricate production requirements. With its ability to execute precise operations, manufacturers can achieve superior quality in their final products, meeting higher industry standards.

- User-Friendly Interface: Designed with operators in mind, it features an intuitive interface that simplifies operation, reducing training time and increasing efficiency. A user-friendly machine allows operators to quickly adapt and ensures that they can focus on production rather than troubleshooting controls.

The Sj 170t in Industrial Applications

The versatility of the Sj 170t makes it a valuable asset across multiple sectors. Its adaptability to different production environments is a significant advantage, facilitating its use in areas such as:

- Automotive Industry: Essential for components manufacturing, the Sj 170t's precision capabilities ensure high-quality finished products. Whether producing engine components or intricate electronic parts, this machine meets the rigorous demands of automotive production.

- Electronics Manufacturing: Its fine-tuned control systems are perfect for assembling delicate electronic components, reducing error rates. As products become smaller and more intricate, the need for precision in electronics manufacturing is paramount, and the Sj 170t excels in this area.

- Textile Production: The machine accommodates various fabric types, enabling efficient mass-production while maintaining quality standards. Producers can leverage the Sj 170t to enhance both the speed and quality of textile output, aligning with consumer demands for faster fashion cycles.

- Consumer Goods Manufacturing: From small household items to complex machinery parts, the Sj 170t handles diverse tasks with ease. Its flexibility allows manufacturers to switch production lines seamlessly without significant downtime.

Advantages of Implementing the Sj 170t

Industries that integrate the Sj 170t within their operations benefit significantly. The primary advantages include:

- Cost-Effectiveness: By reducing waste and energy consumption, the Sj 170t lowers operational costs, offering a compelling return on investment. The machine's efficiency means that companies can process more units while utilizing less energy per unit, a critical factor in today’s cost-sensitive environment.

- Scalability: Adaptable to varying production scales, it supports business growth and expansion without requiring substantial additional investment. Companies can increase production capacity with the same equipment, allowing for strategic scaling in response to market demands without the need for drastic operational changes.

- Environmental Impact: Designed with sustainability in mind, the Sj 170t contributes to reduced environmental footprints through efficient resource use. As industries strive to meet environmental guidelines and consumer expectations for sustainability, the Sj 170t stands as a robust solution that aligns with these values.

Expert Insights on the Sj 170t

Experts in the industry recognize the Sj 170t for its advanced manufacturing capabilities. As noted by leading industrial engineers, its contribution to increasing production efficiency and quality assurance stands out. Furthermore, manufacturers appreciate the machine's ability to integrate seamlessly into existing production lines, offering flexibility without compromising performance. Industry professionals also note the Sj 170t's ability to provide data-driven insights, fostering a culture of continuous improvement within the manufacturing processes.

Future Developments

Looking forward, the Sj 170t is positioned for further enhancements, with potential upgrades focused on augmenting its digital connectivity features and incorporating AI-driven analytics to predict maintenance needs. Such advancements are anticipated to enhance its utility, paving the way for smarter, more responsive manufacturing processes. Manufacturers may be able to harness real-time data to fine-tune operations further, maximizing efficiency and minimizing costs through predictive analytics and machine learning algorithms.

Comparative Analysis: The Sj 170t Vs. Competitors

To better understand the position of the Sj 170t in the market, it is essential to conduct a comparative analysis with similar machines from competitors. This section will examine noteworthy alternatives, highlighting differentiating factors.

- Competitor A: The Bx 1500, while similar in efficiency, tends to have a slower adjustment mechanism, affecting overall adaptability in production lines. This can make a considerable difference in environments requiring rapid changes or adjustments.

- Competitor B: The Cg 200 emphasizes speed but lacks the precision control that the Sj 170t uniquely offers. Consequently, manufacturers might opt for the Sj 170t for tasks where quality assurance is prioritized, despite the slightly longer processing time.

- Competitor C: The Sz 250, which boasts a lower initial cost, may lead to higher operational expenses over time due to its less robust construction, leading to increased maintenance requirements and a shorter lifespan.

These comparisons illustrate that while there are various machines available, the Sj 170t strikes a balance between efficiency, durability, and precision, making it a worthy investment for businesses focused on long-term success and sustainability.

Real-World Use Cases of the Sj 170t

Examining specific real-world applications of the Sj 170t provides further insights into its operational capabilities and benefits in diverse settings:

- Automotive Components: A leading automotive manufacturer implemented the Sj 170t for producing engine parts. The precision of the machine reduced the defect rate to below 1%, which significantly improved customer satisfaction and reduced costs associated with rework.

- Electronics Assembly: A mid-sized electronics firm adopted the Sj 170t to optimize its assembly line. With enhanced control capabilities, the company noted a 25% decrease in assembly time, allowing for faster turnaround in fulfilling customer orders.

- Textile Applications: In a textile facility, the forward-thinking use of the Sj 170t allowed for the production of hybrid fabrics, accommodating diverse fibers without compromising quality. This flexibility helped capture new market segments, catering to the growing consumer preference for sustainable and versatile textiles.

- Consumer Products Manufacturing: A household products company utilized the Sj 170t in creating new kitchen gadgets. The machine’s precision control facilitated the assembly of complex parts, leading to a successful product launch that exceeded sales forecasts, demonstrating the market's readiness for innovation.

Training and Support for Sj 170t Users

To ensure that operators maximize the potential of the Sj 170t, comprehensive training and support are critical components of successful implementation. Companies that invest in proper training typically experience:

- Reduced Learning Curve: Through structured training programs, operators can quickly become proficient in using the machine, ensuring that production remains steady.

- Enhanced Problem-Solving Skills: A deeper understanding of the machine's capabilities allows operators to troubleshoot minor issues independently, minimizing downtime.

- Ongoing Support: Many manufacturers offer ongoing technical support and software updates, ensuring that the Sj 170t adapts to evolving production needs and continues operating at peak performance.

The investment in training and support not only prepares operators for immediate challenges but also fosters a culture of continuous improvement and operational excellence within the organization.

FAQs

- What makes the Sj 170t unique compared to other machines?

- The Sj 170t's unique combination of precision, efficiency, and adaptability sets it apart from other industrial machines. Its user-friendly design and robust construction further enhance its appeal, making it an ideal choice for manufacturers aiming for high-quality production.

- Is the Sj 170t suitable for all types of production facilities?

- While highly versatile, it is essential to assess specific production needs and facility requirements to ensure the best fit for the Sj 170t. Customizing the machine's parameters may be required for optimal functionality in certain specialized environments.

- How does the Sj 170t contribute to sustainable manufacturing?

- By optimizing resource use and minimizing waste, the Sj 170t supports sustainable practices, aligning with green manufacturing goals. Its design allows manufacturers to meet or exceed regulations regarding waste management and energy consumption.

- Can the Sj 170t be integrated with existing systems?

- Yes, the Sj 170t is designed to integrate smoothly into both new and existing manufacturing systems, enabling businesses to leverage their current setup while enhancing productivity.

- What type of maintenance does the Sj 170t require?

- Regular maintenance generally includes routine inspections, calibration checks, and timely updates to software systems. Many providers also suggest establishing a maintenance schedule based on usage patterns to prolong the machine's lifespan effectively.

Conclusion

The Sj 170t represents a significant stride in the realm of industrial machinery, combining efficiency with versatility to meet contemporary manufacturing needs. As industries continue to gear towards scalable and sustainable production solutions, the Sj 170t offers an innovative and reliable choice, ensuring efficiency and quality in various applications. With advancements in technology pushing the boundaries of manufacturing capabilities and expectations, investing in such machines can set industries apart in a competitive market. The Sj 170t stands as a beacon for future innovations in manufacturing processes, indicating a strong future for businesses that prioritize efficiency, quality, and sustainability.

| Features |

Benefits |

| High Efficiency |

Increased productivity with minimal downtime |

| Precision Control |

Accurate adjustments for intricate production |

| User-Friendly Interface |

Ease of operation reducing operator training time |

| Durable Construction |

Long-lasting performance decreasing maintenance needs |

| Robust Analytics |

Data-driven insights enhancing operational efficiency |

| Seamless Integration |

Compatible with existing machinery, maximizing ROI |