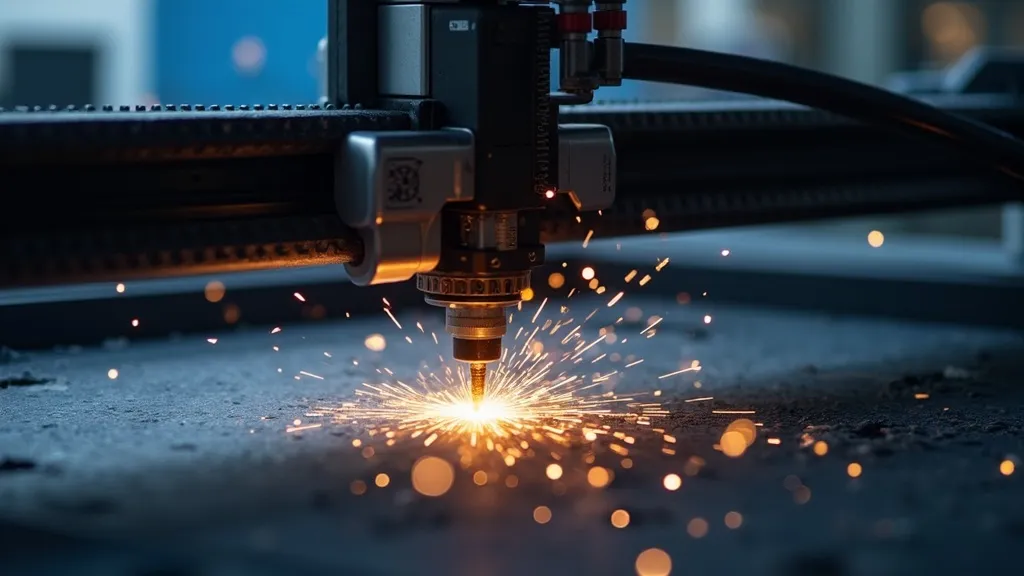

This article delves into the world of Mrk Laser technology, a critical component in modern manufacturing and industrial applications. Mrk Laser systems are renowned for their precision and efficiency, transforming how industries approach cutting, engraving, and marking processes. By exploring the capabilities and advantages of Mrk Laser, this guide provides valuable insights for businesses seeking innovative solutions.

In the rapidly evolving landscape of industrial manufacturing, laser technology stands out as a pivotal innovation. Among the very advanced systems is the Mrk Laser, known for its precision, versatility, and efficiency in a range of applications. This article explores the intricacies of Mrk Laser technology, shedding light on how it is revolutionizing various industries by enhancing productivity and ensuring high-quality output.

Mrk Laser refers to a specific brand and type of laser technology utilized in numerous industrial applications. These systems are designed to provide high precision in tasks such as cutting, engraving, and marking on a variety of materials. The technology's ability to deliver consistent results with minimal waste makes it a popular choice in sectors ranging from automotive to electronics. Unlike traditional methods, Mrk Laser technology employs focused light beams that deliver energy to materials with remarkable accuracy, allowing for intricate designs and patterns that were previously difficult or impossible to achieve.

The adoption of Mrk Laser technology offers numerous benefits, including:

Mrk Laser technology is employed across various industries, each benefiting from its unique capabilities:

| Model | Power Output | Material Compatibility | Key Features |

|---|---|---|---|

| Mrk Laser X100 | 100W | Metals, plastics | High-speed processing, ideal for small to medium-scale production. |

| Mrk Laser Z200 | 200W | Wider material range, including wood and composites | Enhanced precision, suitable for intricate designs and larger projects. |

| Mrk Laser Pro 300 | 300W | High-density materials, thick metals | Advanced cooling system, designed for heavy-duty applications. |

| Mrk Laser Mini 50 | 50W | Light materials, such as paper and fabric | Compact size, perfect for small workshops and startups. |

| Mrk Laser Eco 150 | 150W | Most metals, plastics, and porous materials | Energy-efficient model, designed for environmentally conscious operations. |

As industries continue to evolve, the demand for advanced laser technologies like Mrk Laser is expected to grow. Several trends are shaping the future of this technology:

To illustrate the profound impact of Mrk Laser technology across various industries, let’s explore some case studies that highlight its applications and benefits:

A leading automotive manufacturer implemented Mrk Laser systems to produce intricate components, such as airbag covers and dashboard inserts. By using laser technology, they achieved remarkable precision, which not only improved the quality of the final products but also significantly reduced production time. The company reported a 30% decrease in material waste and a 20% increase in production efficiency, allowing them to meet the growing demand for vehicles without incurring additional costs.

In the electronics sector, a prominent company adopted Mrk Laser technology for the production of circuit boards. The precision of the laser systems enabled the manufacturer to etch fine lines and patterns, resulting in smaller and more efficient circuit designs. Additionally, the speed of the laser cutting process allowed for faster turnaround times, enabling the company to keep pace with market demands. The overall implementation led to a cost reduction of 15% in production expenses.

A renowned jewelry designer utilized Mrk Laser systems to create custom pieces with intricate engravings. The technology allowed for the production of detailed designs that were previously unattainable through traditional methods. The designer reported an increase in customer satisfaction due to the unique, personalized offerings and a boost in sales as a result. The ability to quickly prototype and iterate designs also shortened the product development cycle, enhancing creativity and innovation within the brand.

A fashion brand incorporated Mrk Laser technology into its production process, utilizing it for cutting and engraving fabrics. The precision cutting reduced fabric waste and allowed for more complex design patterns. The brand experienced a 25% increase in design options available to customers, leading to higher sales and improved brand loyalty. Furthermore, the eco-friendly nature of the laser cutting process aligned with the brand’s commitment to sustainability, enhancing its market position.

Mrk Laser technology continues to be at the forefront of industrial innovation, offering unmatched precision and efficiency. As industries strive for higher standards of production and quality, Mrk Laser systems provide a reliable solution that meets these demands effectively. The versatility of Mrk Laser technology allows it to be adapted for various applications, from automotive to jewelry, making it an essential tool in modern manufacturing. For businesses looking to optimize their manufacturing processes, investing in Mrk Laser technology is a strategic decision that promises significant benefits, including cost savings, increased productivity, and enhanced product quality.

Looking ahead, the integration of advanced technologies such as automation and IoT in Mrk Laser systems will likely continue to propel the industry forward. As manufacturers embrace these innovations, the potential for Mrk Laser technology to further transform the manufacturing landscape is immense. Companies that adopt this technology will not only improve their operational efficiency but also position themselves as leaders in an increasingly competitive market.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!