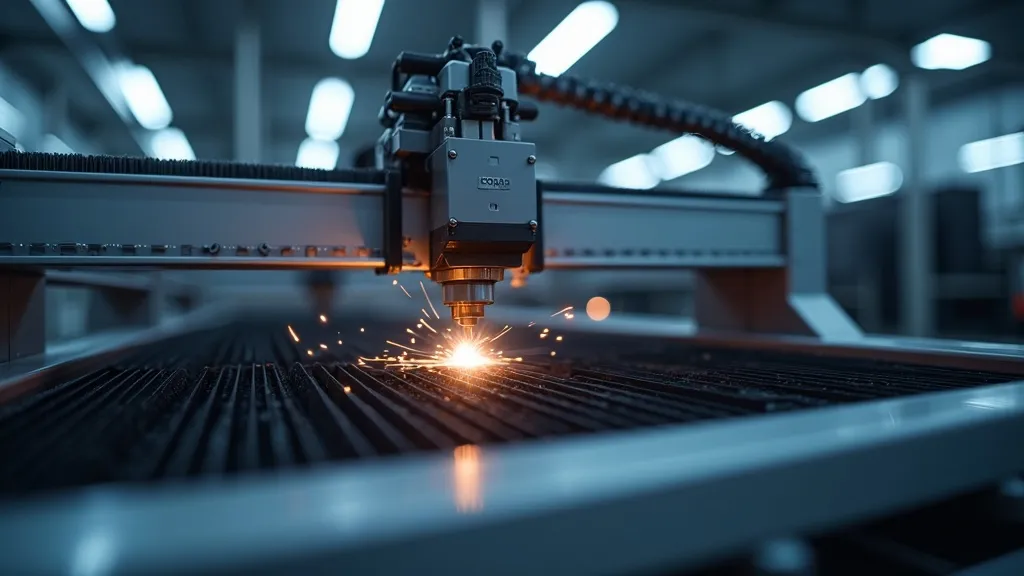

Mrk Laser represents a significant advancement in precision laser technology, offering unparalleled accuracy and efficiency in industrial applications. This article delves into the intricacies of Mrk Laser, exploring its technological features, industry applications, and the competitive advantages it offers to businesses seeking cutting-edge solutions. Additionally, it provides insights into the operational requirements and benefits of utilizing such advanced equipment in today's market.

In the ever-evolving landscape of industrial technology, Mrk Laser stands out as a beacon of precision and innovation. As industries strive for accuracy and efficiency, Mrk Laser delivers solutions that meet the highest standards of quality. In this article, we explore the comprehensive features of Mrk Laser systems, their applications across various sectors, and the benefits they bring to modern manufacturing and production processes. By delving deeper into the intricacies of Mrk Laser technology, we aim to provide readers with a holistic understanding of its role in shaping the future of industrial applications.

Precision laser technology has come a long way since its inception. Initially developed for scientific applications, lasers have now become an integral part of industrial settings. The evolution of laser technology is marked by improvements in power, accuracy, and versatility. Mrk Laser has emerged as a leader in this evolution, offering products that cater to diverse industrial needs, from material processing to intricate cutting tasks. This journey of innovation has included advancements such as fiber lasers, which provide higher efficiency and lower operational costs, and solid-state lasers, which offer enhanced durability and performance in demanding environments.

Moreover, the integration of digital controls and automation in laser systems has revolutionized how industries operate. With the ability to program laser systems for various tasks, manufacturers can achieve a level of customization that was previously unattainable. The continuous research and development efforts at Mrk Laser ensure that their technologies not only keep pace with the latest advancements but also set benchmarks for others in the sector.

Mrk Laser systems are renowned for their high precision and reliability. These systems incorporate advanced laser optics and sophisticated control mechanisms, enabling them to perform complex tasks with minimal error margins. The integration of cutting-edge software further enhances the capabilities of Mrk Lasers, allowing for seamless customization and adaptability to various industrial processes. Additionally, the user interface is designed to be intuitive, enabling operators to quickly learn how to maximize the system’s potential without extensive training.

One of the standout features of Mrk Laser systems is their ability to automate processes, which significantly reduces the likelihood of human error. Automation not only improves consistency but also enhances overall productivity by allowing machines to operate continuously without fatigue. This is particularly beneficial in high-demand environments where maintaining output levels is critical. Furthermore, Mrk Laser systems are designed to be easily integrated into existing production lines, minimizing downtime during installation and ensuring a smooth transition for manufacturers.

Mrk Laser technology is utilized across a wide range of industries, each benefiting from its precision and efficiency. In the automotive sector, for example, Mrk Lasers are used for cutting and welding components with exacting precision. The ability to perform intricate cuts and welds ensures that parts fit together perfectly, which is crucial for the safety and performance of vehicles. The laser cutting process also allows for intricate designs and shapes that traditional cutting methods cannot achieve.

The electronics industry employs these lasers for micro-processing tasks, ensuring the integrity and performance of intricate circuitry. The precision that Mrk Lasers provide is essential for manufacturing components such as circuit boards, where even the smallest error can lead to significant functional issues. Moreover, the speed at which these lasers operate means that production can keep pace with the rapid advancements in technology, meeting consumer demand effectively.

Additionally, Mrk Laser systems are pivotal in the medical field for manufacturing precise medical instruments and devices. The healthcare sector demands not only precision but also stringent safety standards, making Mrk Lasers an ideal choice for tasks such as cutting surgical instruments or engraving medical implants. The technology’s ability to produce consistent and reproducible results is vital in ensuring that medical devices meet regulatory requirements and function as intended.

Beyond these sectors, Mrk Laser technology has found applications in industries such as aerospace, where it is used for cutting and welding lightweight materials, and in textiles, where it can cut complex patterns in fabrics with remarkable accuracy. The versatility of Mrk Lasers enables them to adapt to the unique requirements of each industry, making them a valuable asset for manufacturers seeking to innovate and improve their processes.

The advantages of employing Mrk Laser systems are manifold. One of the primary benefits is the unparalleled precision they offer, which is crucial for industries where accuracy is paramount. The ability to achieve tolerances in the micrometer range ensures that products meet stringent specifications and quality standards. This high level of precision not only enhances product quality but also reduces the need for rework and scrap, leading to cost savings for manufacturers.

Furthermore, Mrk Lasers are designed for efficiency, reducing production time and minimizing material wastage. The focused energy of laser beams allows for faster cutting speeds compared to traditional methods, which translates to shorter cycle times and increased throughput. This efficiency is particularly beneficial in high-volume production environments, where every second counts. By optimizing production processes, companies can meet deadlines more effectively and respond to market changes with agility.

Their versatility allows them to handle a wide array of materials, from metals to polymers, making them a valuable asset for manufacturers. This adaptability means that businesses do not need to invest in multiple machines for different materials, simplifying operations and reducing capital expenditure. Additionally, Mrk Lasers can be programmed to switch between different tasks and materials with ease, enabling manufacturers to diversify their product offerings without significant investment in new technology.

Another significant advantage is the cleanliness of the laser cutting process. Unlike traditional cutting methods that may produce debris or require secondary finishing processes, laser cutting is a non-contact method that produces minimal waste. This not only enhances the working environment but also reduces the need for additional cleanup and maintenance, further improving operational efficiency.

Implementing Mrk Laser technology requires an understanding of specific operational requirements. These systems need to be housed in environments that ensure optimal performance, including controlled temperature and humidity levels. Fluctuations in environmental conditions can affect the performance of the laser, leading to inconsistencies in output quality. Therefore, it is essential to create a stable environment that supports the operation of these advanced systems.

Additionally, operators must be trained to handle the equipment safely and efficiently, ensuring the longevity and consistent performance of the laser systems. Training programs should cover not only the technical aspects of operating the machines but also safety protocols, as lasers can pose hazards if not handled properly. Regular maintenance checks and calibrations are also essential to maintain the accuracy and reliability of the systems over time.

Moreover, organizations should consider the integration of Mrk Laser technology within their existing workflows. This includes assessing how the new systems will interact with current machinery and processes, as well as planning for potential workflow adjustments. Effective integration can enhance overall productivity and reduce disruptions during the transition period.

| Feature | Mrk Laser | Traditional Laser Systems |

|---|---|---|

| Precision | High | Moderate |

| Efficiency | High | Varies |

| Versatility | Wide Range of Materials | Limited to Specific Materials |

| Operating Costs | Low | Higher due to energy consumption |

| Maintenance Requirements | Minimal | Higher due to wear and tear |

| Setup Time | Quick | Longer due to calibration |

In conclusion, Mrk Laser technology represents a significant leap forward in industrial laser applications. Its precision, efficiency, and versatility make it an invaluable tool for modern manufacturing. The continuous evolution of technology within this field ensures that Mrk Lasers will remain at the forefront of innovation, meeting the growing demands of various industries. As industries continue to evolve, adopting advanced technologies like Mrk Laser will be crucial for maintaining competitive advantage and achieving high-quality production outputs.

Moreover, as businesses strive to adopt more sustainable practices, the eco-friendly benefits of laser technology will play a pivotal role in shaping future manufacturing processes. The reduction of material waste and energy consumption not only contributes to cost savings but also aligns with global sustainability goals. In this light, Mrk Laser technology is not just about enhancing productivity but also about fostering responsible manufacturing practices that benefit the environment.

Looking forward, we can anticipate further advancements in laser technology, including developments in artificial intelligence and machine learning that will enhance automation and predictive maintenance capabilities. Such innovations will undoubtedly expand the horizons of what is possible with laser systems, paving the way for even more sophisticated applications across various sectors. As we embrace these technological advancements, Mrk Laser stands poised to lead the charge, shaping the future of industrial processes and redefining standards of excellence in precision manufacturing.

Explore the Tranquil Bliss of Idyllic Rural Retreats

Ultimate Countdown: The 20 Very Legendary Gaming Consoles Ever!

Understanding Halpin and its Influence

Affordable Full Mouth Dental Implants Near You

Discovering Springdale Estates

Illinois Dentatrust: Comprehensive Overview

Embark on Effortless Adventures: Unveiling the Top in Adventures Made Easy Outdoor Equipment

Unveiling Ossur Valves: Innovation in Prosthetics

Unlock the Full Potential of Your RAM 1500: Master the Art of Efficient Towing!